CNC Hydraulic Punching Machine Maintenance Matters

1. Often check whether the equipment safety measures are effective, CNC hydraulic punching machine "emergency stop" button are mechanically locked, must be rotated to reset. To make the machine start, you must make all the emergency stop button reset.

2. Daily check whether there is leakage in the hydraulic pipeline, gas line, pressure is normal, water cooling is good. Check whether the outer skin layer of the high-pressure hose is intact, and whether there is any pull-off near the joint, and replace it in time if necessary to avoid cracking.

3. CNC hydraulic punching machine oil should be strictly filtered before adding to the oil tank, the oil tank filling volume is not less than the requirements of the oil label.

4. The oil temperature should never exceed 50 ℃, otherwise the system will be damaged. For equipment that is not used for a longer period of time, the piston rod of the oil cylinder must be retracted into the oil cylinder to prevent rusting.

5. Listen to the normal operation sound at the motor, pipeline, solenoid valve and oil tank of the equipment every week.

6. Check the water divider filter, oil mist, pressure regulator and pressure gauge every week. Check and calibrate the pressure gauge once every six months.

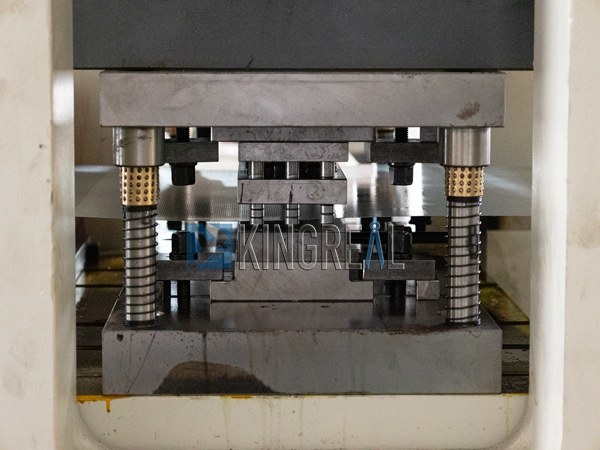

7. Inject oil into the die holder, punch rod and guide block once per shift before starting to use the hydraulic punching machine.

8. The moving parts on the machine, when moving, will be beyond the range of the machine base and the ground feet. Therefore, no one is allowed to enter the above-mentioned dangerous area when the machine is running.

9. When the machine is operating, the ambient temperature should be at 10℃~40℃, the corresponding humidity should be less than 75%, and all cables should be protected from rat bites.

10. When lifting materials and workpieces, it is strictly forbidden to collide with the equipment or pass over the equipment.

11. The movement of the workpiece, relying on the guide rail and screw to ensure the positioning accuracy, should pay attention to keep clean, no foreign objects fall into it to cause obstruction.

12. The oiling hole of the die holder, the oiling hole of the slider and the moving parts should be cleaned before each start, and the guideway surface and the screw of the punching machine should be oiled once a shift, and the sliding surface should be blown clean with an air gun every shift for iron chips or grease.

13. The operator in the operation of hydraulic punching machine work, not away from their posts. Indeed, when the situation is left, should stop, cut off the power.

14. The machine in the work or adjustment, the fingers are strictly prohibited into the jaws.

15. The operator shall not adjust the system pressure without permission, if necessary, must notify the repair staff, must be responsible for the repair staff to adjust.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima