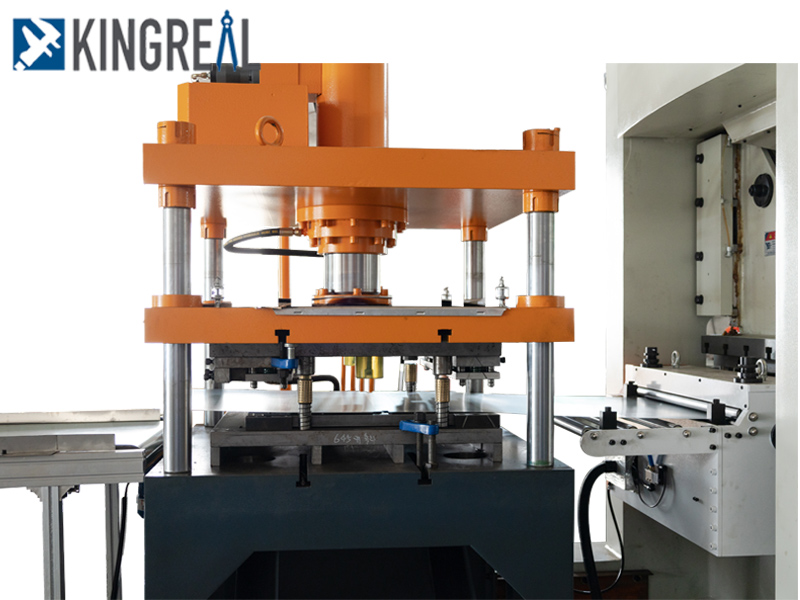

What is Automatic Punching Machine?

Punching machine is a very practical production tool, for our industrial production to improve efficiency has made a great contribution, in fact, punching machine has a lot of aliases, we may usually have heard of, but do not know what is something, today we will talk about these aliases.

Since the punching machine from the development to today only less than twenty years, the development in the country is only a dozen years, all the current there are many imperfections, not to mention the absence of a unified industry standard, so the current name alone there are more than a dozen.

The general accurate call called punching machine, also known as CCD punching machine, many people called target punching machine, Japan, Taiwan, Guangdong area called perforating machine, eye piercing machine or point eye machine, and many people called shooting machine, punching target machine, etc., in fact, all refer to the same product.

Punching machines can be divided into manual punching machines, automatic positioning/alignment punching machines, automatic punching machines, super automatic punching machines, etc. according to the degree of automation.

According to the processing object, it can be divided into soft board punching machine and membrane switch punching machine.

(1) An incomplete gear mechanism is used as the gap motion mechanism.

When the main gear 1 rotates for one week, the driven gear 2 rotates for a quarter of a week, and the driven gear stops four times per revolution. When the driven gear stops, the locking arc on the master gear and the locking arc on the driven gear cooperate with each other to lock to ensure that the driven gear stops at the locked position.

When the motor rotates at high speed, the incomplete gear mechanism, the angular velocity of the master gear increases, the angular velocity of the driven gear also increases, and the inertia force increases during operation. At this point, jamming between gears can easily occur. For this reason, an elastic damping system is added to the system.

The inertia force of the gears is overcome by adjusting the spring force. If high speed operation is required and the gears have high inertia forces, the spring force should be increased, otherwise the spring force should be reduced.

(2) Using the guiding function of the punching die, the slider mechanism of the punch is eliminated; due to the small punching force, the flywheel mechanism of the punch is eliminated, making the whole mechanism simplified and easy to process.

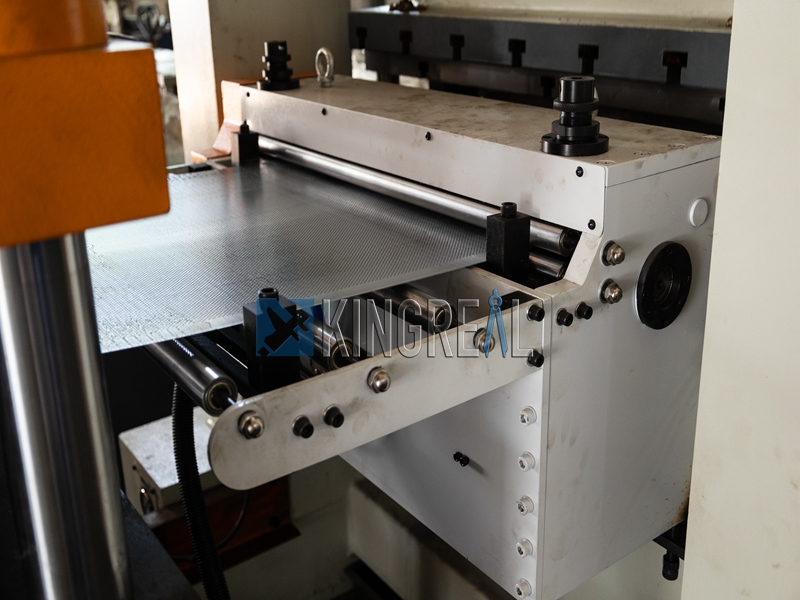

(3) The die is usually mounted vertically on the punch to complete the punching task. Using the existing die holder, considering the safety cap of the vibrating hopper is horizontal, the punching die should be placed horizontally, i.e., the punching task should be done in horizontal direction.

(4) It is a small punch and feeding mechanism in itself, which solves the contradiction of occupying other punches.

(5) In the past, manual feeding was used in the production, which was often not in place and could lead to crushing hand injury accidents. This mechanism solves the problem of press hand and improves the feeding accuracy.

(6) The punching machine used in the past had high-power, high-power consumption and high cost. The power consumption of this mechanism is 500W, which greatly saves energy and reduces the cost.

(7) The invention adopts stepless variable speed, which can adjust the punching speed arbitrarily.

To maintain the automatic punching machine in this way.

1. Ensure that the mechanical punch is wet for a long time. A wet punch can effectively reduce the resistance when punching, reduce the degree of wear and tear of the punch, and extend the service life.

2. Ensure that the compressed air is dry. Compressed air must be dry when using, and the solenoid valve must not enter the water, otherwise it is easy to rust damage.

3. Do not use hard objects to knock on the body. Hard objects knocking easily on the automatic punching machine damage, affecting the normal operation of the equipment.

4. Routine inspection before use. Insist on checking whether there are foreign objects between the punch and the lower die before use to avoid accidents.

5. Reasonable choice of lubricant. Use high quality automatic punching machine lubricant without color and moisture can achieve better use and maintenance effect.

Click here to learn about the automatic punching line you need.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima