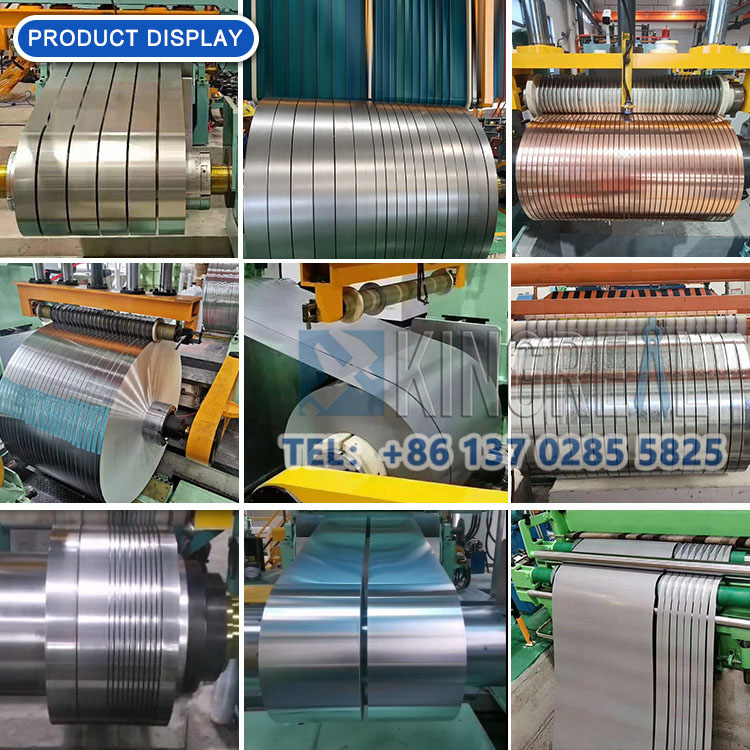

Coil slitting machine is an indispensable and important equipment in the metal processing industry. It plays a key role in the processing of coils. With the diversification of industrial production needs, improving the product quality of the metal slitting line has become the focus of every manufacturer and user.

This article will analyze how the coil slitter can improve product quality, focusing on the importance of product quality to the enterprise, the key factors affecting product quality, and how to ensure the cutting accuracy and consistency of the coil slitting machine through technical and management means.

Importance of product quality

In modern manufacturing, the quality of products directly determines the competitiveness of enterprises. For slitting processing, quality and consistency are crucial. Product quality not only affects the efficiency of the production line, but also determines customer satisfaction and trust, which in turn affects the brand image and market share.

Key factors affecting product quality

In the slitting process, multiple factors will affect the quality of the final product. The following are some of the key factors:

1. Material quality

Material is the most basic raw material in slitting processing, and different types of metal materials have different effects on cutting effects. Taking steel and aluminum as examples, steel has a higher hardness and requires stronger tools and more precise operations when cutting. Aluminum is softer, and although it is relatively easy to cut, if the tool wears too quickly, it will also affect the cutting quality. Therefore, using high-quality raw materials can effectively improve the cutting accuracy and consistency of the metal slitting line. In order to ensure the quality of the product, qualified metal materials must be selected and the process parameters of the coil slitting line must be adjusted according to the material characteristics.

2. Adjustment and configuration of the coil slitter

The adjustment of the coil slitting machine is another important factor affecting product quality. The precise adjustment of the tool, tension control, speed setting, etc. will directly affect the accuracy and consistency of the cutting. For example, if the gap of the tool is too large, it is easy to have "burrs" during cutting, affecting the appearance quality of the product; if the tool angle is not appropriate, it will also affect the cutting effect. The speed control of the coil slitting machine is also very important. Too fast speed may lead to uneven cutting, and too slow speed may affect production efficiency. In addition, tension control also plays a decisive role in the uniformity and stability of the coil.

3. Factory environment

Sometimes, the conditions of the factory environment will also affect the processing effect of the metal slitting line. Factors such as ambient temperature and humidity may cause changes in the physical properties of metal materials, thereby affecting cutting accuracy. For example, in a high temperature environment, the expansion of the metal may cause dimensional deviations during the cutting process, while excessive humidity may cause corrosion on the metal surface, affecting the cutting quality. Therefore, the factory must maintain appropriate temperature and humidity conditions to reduce the impact of the external environment on product quality.

How does the coil slitting machine ensure product quality?

1. Automatic control system

Modern coil slitters are generally equipped with advanced automatic control systems that can accurately monitor and adjust cutting parameters. The automatic system can automatically adjust parameters such as speed and tension in real time according to the different materials, the operating status of the equipment and the processing requirements, thereby ensuring that each cut has the same accuracy.

2. Precise control and optimization of the tool

The tool is the core component of the coil slitting line, and the quality and configuration of the tool directly determine the cutting effect. KINGREAL SLITTING coil slitting machines pay more attention to accuracy and durability in tool design.

First of all, the sharpness of the tool directly affects the quality of the cutting. Sharp tools can reduce friction and avoid burrs.

Secondly, the material of the tool also needs to be optimized according to different processing materials. Carbide tools are usually more suitable for processing metal materials with higher hardness.

In addition, the installation accuracy of the tool is also crucial. The distance between the tool and the coil must be accurate to the millimeter level, otherwise it is easy to cause uneven cutting and affect the quality of the finished product.

3. Continuous equipment maintenance and care

The long-term stable operation of the coil slitting machine requires good maintenance and care. Regularly checking the tool, transmission system, automatic control system and other components, and timely cleaning and replacing wearing parts can effectively ensure the normal operation of the coil slitting machine and avoid fluctuations in cutting quality caused by equipment failure. At the same time, reasonable equipment maintenance can extend the service life of the coil slitting line, reduce maintenance costs, and ensure the continuous and efficient operation of the production line.