KINGREAL SLITTING builds the NEWS column to help everyone learn more about the cutting-edge technology and industry trends in the field of more professional metal slitting machines and cut to length line, and provide professional equipment knowledge and application solutions for manufacturing users.

At the same time, update the latest developments of KINGREAL SLITTING, including the company's participation in exhibitions, customer visits, case sharing, after-sales installation, technological innovation, etc. Help everyone understand the most vivid KINGREAL SLITTING.

If you want to know more about our consultation or are interested in our metal slitting machines and cut-to-length shearing lines, please contact us!

The following is a description of the content of the popular column:

1. Technical analysis of metal slitting machines

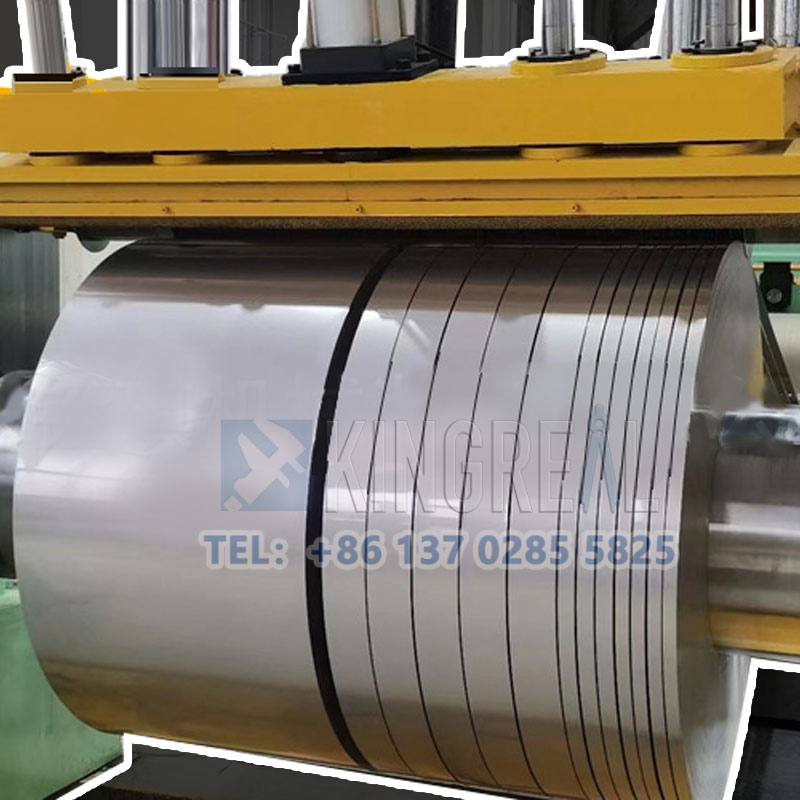

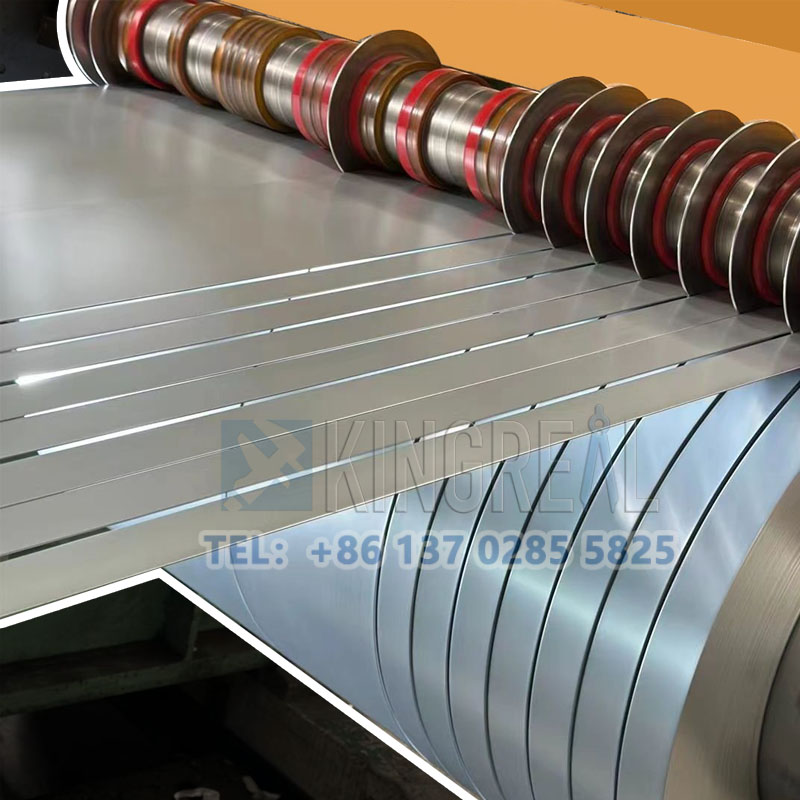

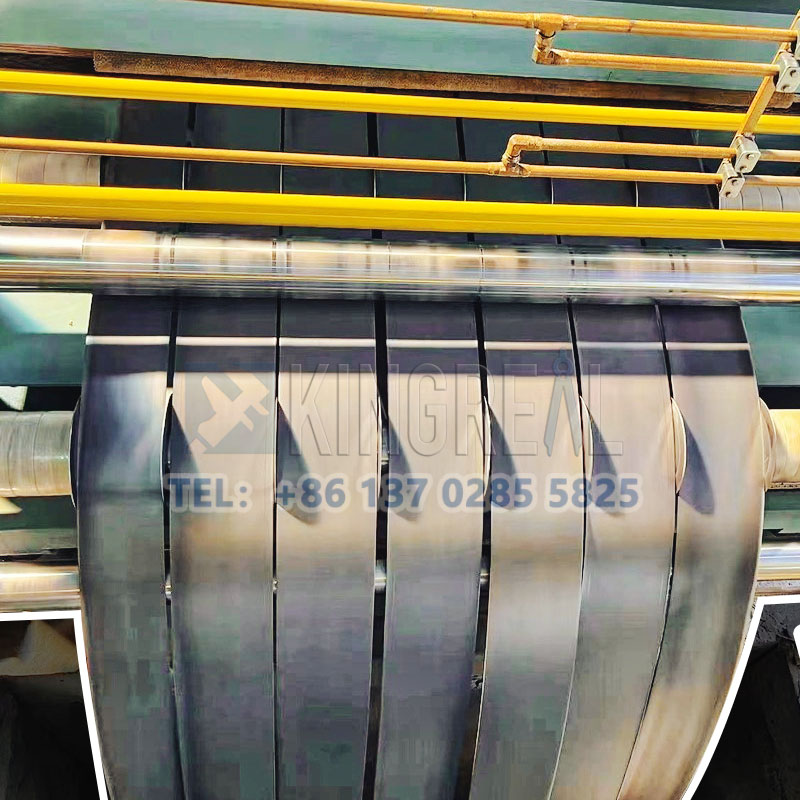

Metal slitting machines are designed to slit metal coils into specified widths and roll them up. High-quality knife seats and tension processes are used to ensure the accuracy and process of coil processing. The most common topics include:

Classification of metal slitting machines: fully automatic/semi-automatic slitting machines, thin/medium/thick material special models

Functional characteristics of metal slitting machines: automatic edge cutting, energy-saving temperature control system, waste edge winding technology, reducing material loss and improving edge flatness

Process flow of metal slitting machines: technical analysis of the entire process from unwinding, leveling, longitudinal shearing to winding, suitable for the processing needs of metal coils such as strip steel and stainless steel

2. Innovative application of cut-to-length line

Equipment types of cut-to-length shearing line: high-speed cut-to-length shearing line, fully automatic cross-cutting line, thick plate slitting unit

Technical parameters of cut-to-length shearing line: shearing thickness (0.1-6.0mm), slitting accuracy (±0.05mm), line speed (up to 200m/min)

Industry adaptation of cut-to-length shearing line: customized shearing solutions for transformer silicon steel sheets, automotive plates, construction steel and other scenarios

3. Equipment operation and maintenance guide

Safety regulations: cut-to-length shearing line shutdown inspection and maintenance sign system, hydraulic system operation precautions

Efficiency improvement: explanation of metal slitting machine step material utilization optimization, knife axis synchronization calibration and maintenance skills

Troubleshooting: slitting machine cutting edge burr control, shearing machine feeding speed matching solution

4. Industry trends and case studies

Application areas: Metal processing innovation cases in the fields of home appliance manufacturing, new energy equipment, and packaging industry

Technological innovation: High-speed slitting production line, double knife holder interchangeable design, digital tension control system

Global dynamics: In-depth interpretation of the energy-saving and automation needs of slitting machines in the European, American and Southeast Asian markets

5. KINGREALSLITTING corporate dynamics

New product launch: Introduction to the latest high-speed longitudinal slitting line, fully automatic cut-to-length shearing line, intelligent stacking system and other equipment

Service upgrade: Global customer technical support system, customized equipment delivery cases

Honorary certification: ISO quality standards, industry technology patent results announcement

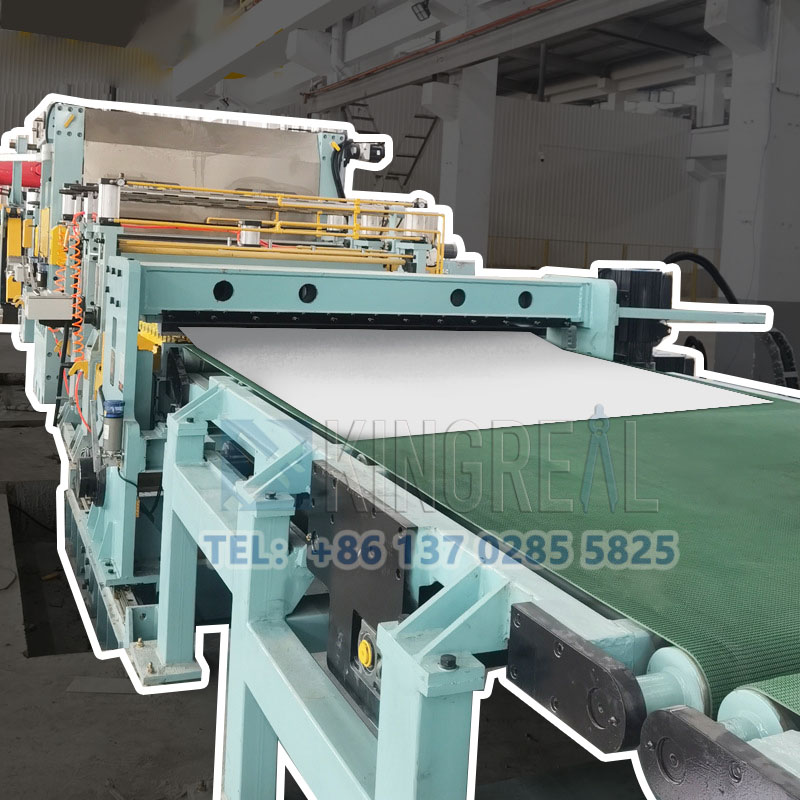

KINGREAL manufacturing the cut to length line for cutting the coil to the sheet. Blanking line for cut to length machine, which is consist of decoiler, straightener, cut to length line and auto stacking of the metal sheet.

More

(0.3-3)×1600MM Steel Slitting Machine is the common blanking line, used to slit the light gauge coil to the narrow strip, can process 0.3-3mm thickness different type material coil. KINGREAL SLITTING insisting on bringing high quality metal slitter solution to our customers.

More

KINGREAL SLITTING provides high speed cut to length blanking line, also called cut to length line, which is a special shearing blanking line specially designed for processing cold rolled coils into the required size by flattening and cutting to length. High speed cut to length line is equipped with fly shearing cut to length device, which can reach 60-80M/Min shearing speed for metal plates. Compared with the common 20-50M/Min shearing speed of metal plates, high speed cut to length machine can help metal processing workshops improve production speed and obtain long-term production benefits.

More

CRGO Silicon steel coil slitting machine is the key equipment in silicon steel sheet processing, silicon steel slitting machine produced by the secondary processing of silicon steel coil is the core material for manufacturing transformer core, motor stator/rotor. Different specifications of electrical equipment require different widths of silicon steel sheet strips, KINGREAL SLITTING silicon steel slitting machine can meet the transformer industry, motor home appliance industry and new energy field for silicon steel raw material processing requirements.

More

What is the feature of heavy duty steel slitting machine? Heavy gauge steel slitting machine can processing 6-20mm thickness metal coil to the narrow strip,can meet the production needs of processing thick or heavy gauge materials

More

The metal slitting line is one of the most important processes in the coil processing line and is used to slit aluminium, steel, galvanized steel, stainless steel, silicon steel and many other different metal coils into small strips of equal width and high precision for final winding. KINGREAL SLITTING is able to provide both high standard and high quality metal slitting lines for large coil processing customers as well as economical solutions for new projects.

More