1. Introduction of Hot Rolled Slitter

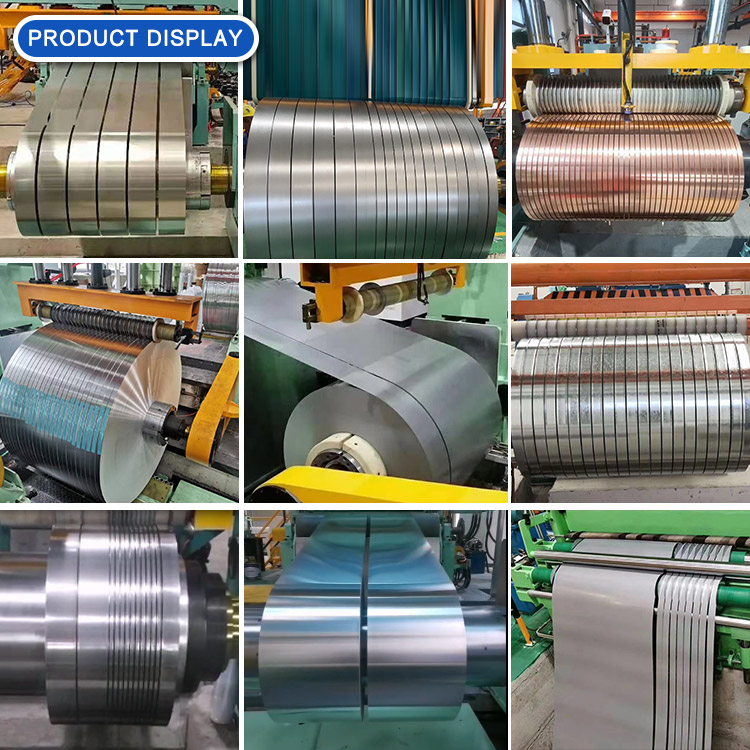

The hr coil slitting machine is a device specially used to process hot-rolled metal coils into narrow strips. By placing the metal coils into the hr slitting line and slitting them according to the narrow strip width required by the customer, the narrow strips can be used for subsequent secondary processing, such as stamping, welding and forming. hr coil slitting machines play a key role in modern industrial production and are widely used in many industries such as automobiles, construction, and home appliances.

2. Reasons for Large Demand for hr slitting lines

The large demand for hot rolled slitter mainly stems from its wide range of applications. The following are some of the main application industries and countries:

(1) Automobile manufacturing

In the automotive industry, the production of various metal parts requires a large number of narrow strips as raw materials. The hr slitting line can split the hot-rolled coils into widths suitable for different body parts to ensure the efficient operation of the production line.

(2) Construction industry

The demand for steel in the construction industry is also growing. The hot rolled slitter can provide steel strips of different widths for the production of structural parts and building materials. Especially in steel structure buildings, the application of hr coil slitting machines is particularly important.

(3) Home appliance industry

Hot-rolled metal strips are usually required for the metal shells and internal structural parts of home appliances. hr slitting lines can provide metal strips of precise width to meet the needs of home appliance manufacturing.

(4) Shipbuilding

In shipbuilding, the processing of hot-rolled metal materials is also inseparable from hr slitting lines. Hot rolled slitter can provide metal strips of various specifications for the manufacture of hulls and internal structures.

✧Demands of various countries

The demand for hr slitting lines is not only in China, but also in Europe, America, Southeast Asia and other countries and regions, which are actively introducing and using such hr coil slitting machine to improve the efficiency and competitiveness of their manufacturing industries.

3. Methods for Achieving Efficient Production of Hot Rolled Slitter

To achieve efficient production of hr slitting lines, optimization and improvement are required from multiple aspects. The following are several effective methods:

(1) Full automation

Equipping hr coil slitting machines with fully automated components is an effective means to achieve efficient production.

(1.1) Automatic packaging line

In order to maximize the automation of the entire slitting process, KINGREAL SLITTING provides a series of automatic coil packaging machines, including:

- Coil strapping machine:This equipment is used to automatically wind the slitting metal strip into a coil for easy storage and transportation. The winding line has a high degree of automation, which can reduce manual operations and improve production efficiency.

- Coil tilter station: This equipment is used to tilt the metal strip at a certain angle after slitting, which is convenient for subsequent processing and packaging. The design of the tilting line can effectively reduce the damage of the metal strip during transportation.

- Vertical packaging line: The vertical packaging line is used to automatically package the slitting metal strip to ensure the neat appearance of each product and improve packaging efficiency. The vertical packaging design can save space and adapt to different production environments.

(2) Equipment selection

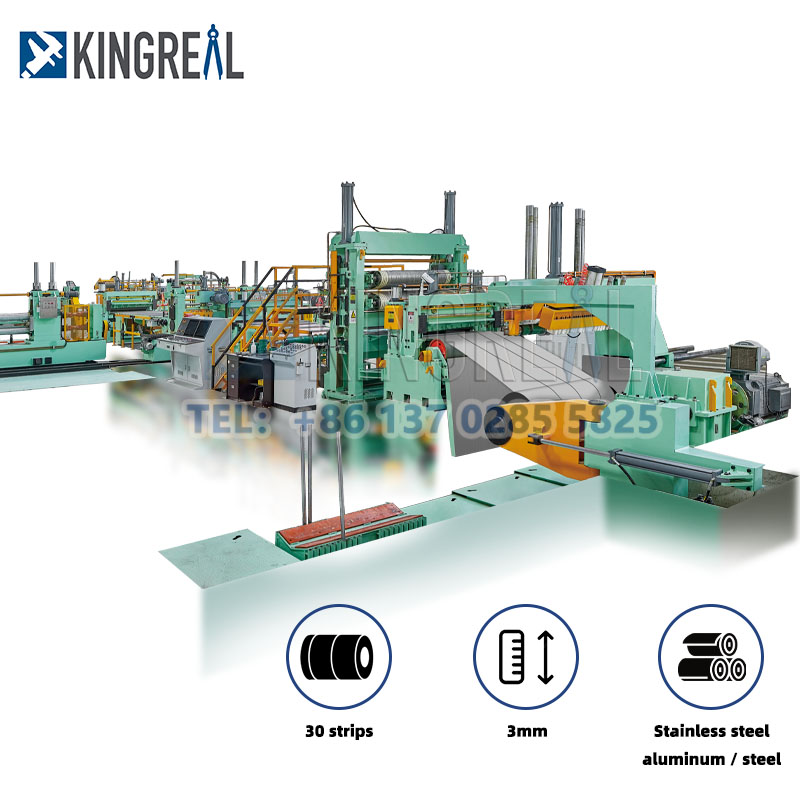

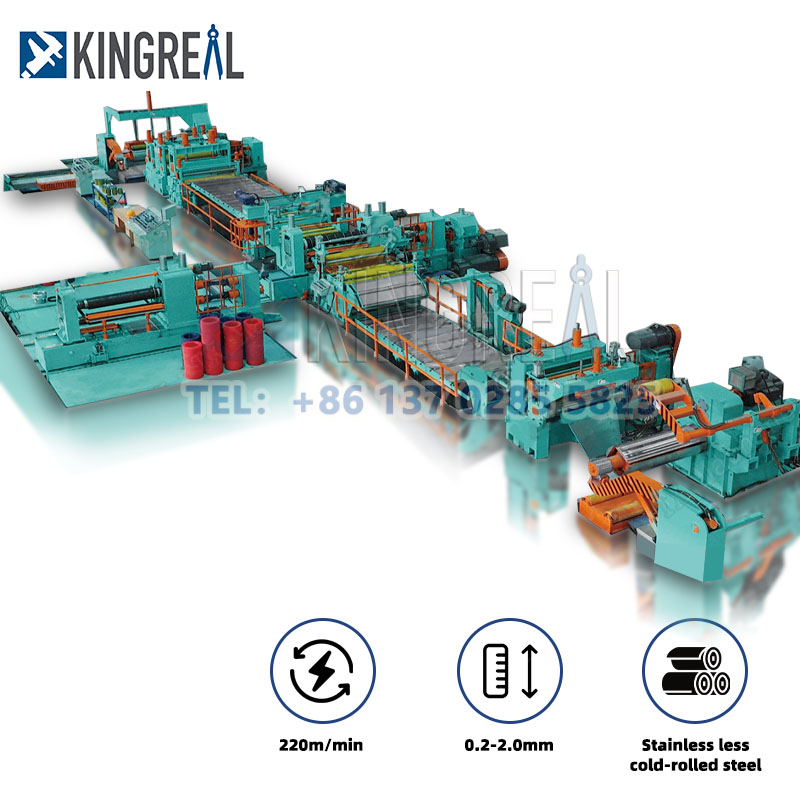

It is very important to choose the right hr slitting line model and match performance with production capacity. KINGREAL SLITTING designs various types of hr coil slitting machines according to the special production needs of customers, such as:

- 1600mm hr slitting line: It can slitting metal coils with a width of 1600mm to meet customers' needs for processing coils with special widths.

- Belt tension hr coil slitting machine: It is used to adjust the tension of the metal belt during the slitting process to ensure the accuracy and quality of the slitting.

- Dual slitter head hot rolled slitter:This design can achieve more efficient slitting and is suitable for the production needs of complex products.

(3) Operation process optimization

Operator training is crucial for the efficient production of hr coil slitting machines. Workers need to have a full understanding of the operation process, precautions, common faults, etc. of the hr slitting line. After installing the hot rolled slitter, KINGREAL SLITTING will provide hr coil slitting machine operation training to customer workers to help them master the correct operation techniques and avoid production accidents caused by improper operation.

(4) Maintenance and care

Regular maintenance and care are important links to ensure the efficient production of hr coil slitting machines. After a long period of operation, the equipment may be worn and malfunction. Regular maintenance can effectively extend the service life of the hr slitting line.

(4.1) Common faults and treatment methods

- Tool wear: The tool is one of the most important parts of the hot rolled slitter. Regularly checking the sharpness of the tool and replacing the worn tool in time can ensure the quality of slitting.

- Unstable tension: If the tension of the metal strip is unstable during the slitting process, it may cause uneven slitting. Check the status of the tension machine regularly to ensure its normal operation.

- Electrical failure: The electrical system of the hr slitting line is a key part. Regularly checking the circuit connection, component status, etc. can avoid downtime caused by electrical failure.

- Lubrication system: Ensuring that the moving parts of the hot rolled slitter are well lubricated can reduce friction, reduce energy consumption, and extend the life of the hr slitting line.