Definition of Coil Slitting Machine

Metal precision metal coil slitter machine is a important tool in the metalworking industry, which consists of a production line composed of a feeder, a slitting host, a tension mechanism, a receiving machine and other machines.

Its function is to slit wide metal, non-metal and composite material coils into many precision narrow coils. Metal coil slitter machines will be slit metal coil, more commonly also includes slitting, stainless steel, copper ... It is mainly used in steel processing plants, rolling mills, electrical industry, automotive, etc. Stamped parts, etc.

KINGREAL SLITTING: An expert in coil slitting machine manufacturing for more than 20 years

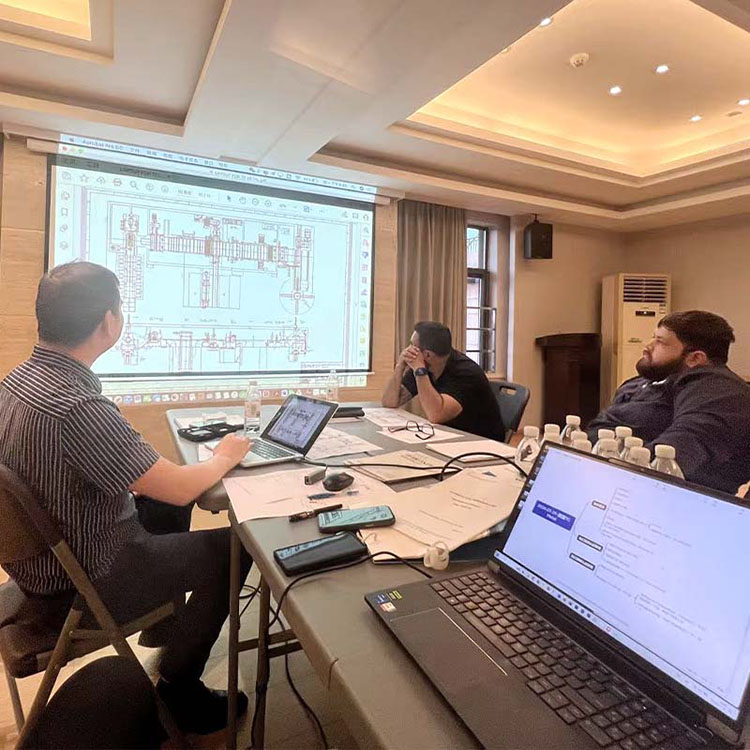

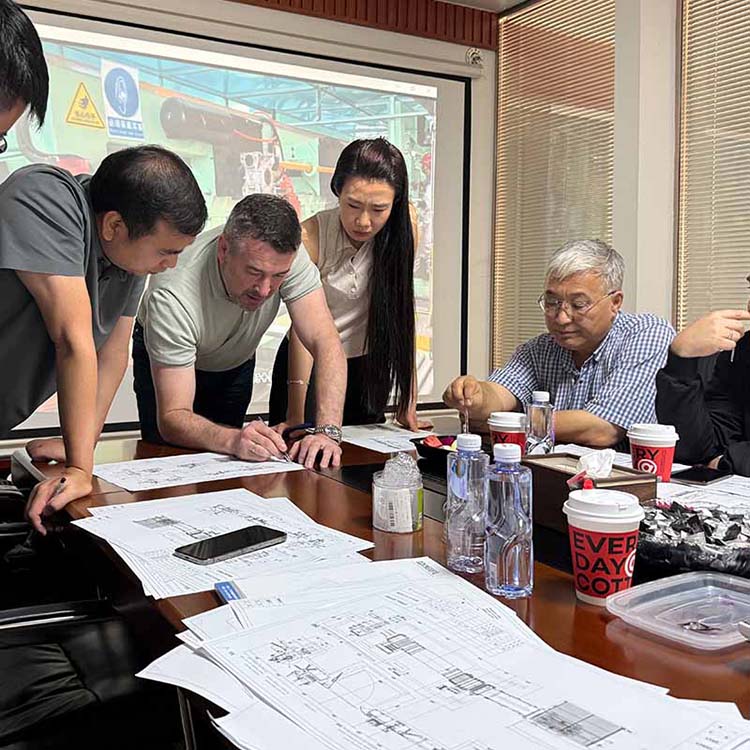

KINGREAL SLITTING has been deeply involved in the field of coil slitting machine manufacturing for more than 20 years. With its rich industry experience and excellent customer service capabilities, it has won wide recognition in the global market. KINGREAL SLITTING not only has a professional customer service team that can respond to customer needs 24 hours a day, but also brings together a group of highly skilled engineers. They are good at providing highly customized metal coil slitter machine solutions based on the specific needs of customers.

So far, KINGREAL SLITTING has successfully sold more than 200 metal coil slitter machines, which have been exported to customer factories in more than 50 countries around the world, including India, Russia, Spain, Italy, Saudi Arabia and other countries, and has established long-term and close cooperative relations with customers in these countries.

Behind the wide praise from customers: rigorous manufacturing process

The reason why KINGREAL SLITTING coil slitting machines can win the trust of customers is not only due to its deep manufacturing experience, but also due to a rigorous machine manufacturing process. From the strict screening of raw materials to the pursuit of excellence in the manufacturing process, to the final machine test, every link pursues excellence. This article will explain in detail how KINGREAL SLITTING ensures the high quality of each metal coil slitter machine.

1. Before machine manufacturing: strict material selection to ensure basic quality

Before manufacturing a high-quality coil slitting machine, the selection of materials is crucial. KINGREAL SLITTING knows that high-quality materials are the foundation of high-quality machines, so it always insists on cooperating with fixed material suppliers to ensure the stability and reliability of raw materials.After each batch of raw materials is delivered, the technicians will strictly test its key indicators such as accuracy, hardness, and toughness. If it is found that it does not meet the standards, the materials will be returned, and substandard raw materials will never be used for production. Such high standards have laid a solid foundation for the quality of the metal coil slitter machine.

2. In machine manufacturing: keep improving and do not miss any details

In the manufacturing process of the coil slitting machine, KINGREAL SLITTING technicians always maintain a high degree of concentration. Even a screw is required to fully match the design specifications of the coil slitting machine. Each component must be strictly inspected to ensure that its performance and quality meet the standards before it can be used for assembly. During the assembly process, engineers carefully check every detail, striving to present a stable and efficient metal coil slitter machine.

3. After manufacturing: multiple rounds of testing to ensure impeccable performance

After the metal coil slitter machine is manufactured, KINGREAL SLITTING will assemble the equipment into a complete production line, including decoilers, coil slitters and other components, and then use metal coils for multiple rounds of testing.The test content mainly covers multiple key indicators such as slitting speed, narrow strip accuracy, and equipment stability. After the first test, the technicians will adjust the equipment parameters according to the test results to ensure that the equipment is in the best condition. If it is found that the equipment cannot meet customer needs, it will be directly judged as an unqualified product and re-produced, and defective products will never be allowed to enter the market.

Behind customer trust: word of mouth and repeat customers

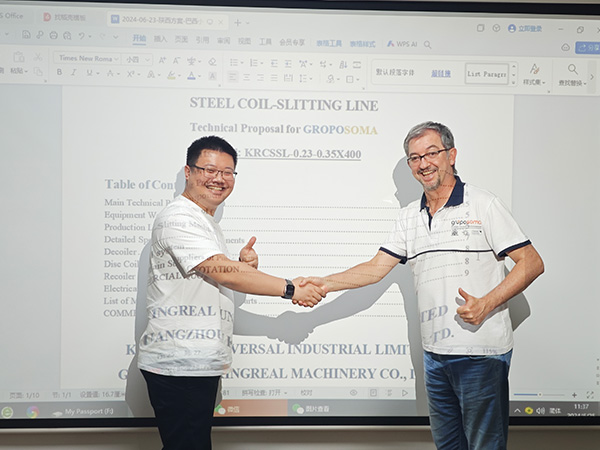

It is precisely because KINGREAL SLITTING has always adhered to a rigorous manufacturing process and a spirit of craftsmanship that pursues excellence that it enjoys a good reputation in the field of coil slitting machine manufacturing. Moreover, many customers have become long-term partners after using KINGREAL SLITTING metal coil slitter machines and have recommended KINGREAL SLITTING to more potential customers.

In the future, KINGREAL SLITTING will continue to be customer-oriented, continuously optimize products and services, and provide more efficient and reliable slitting machine solutions for global customers.