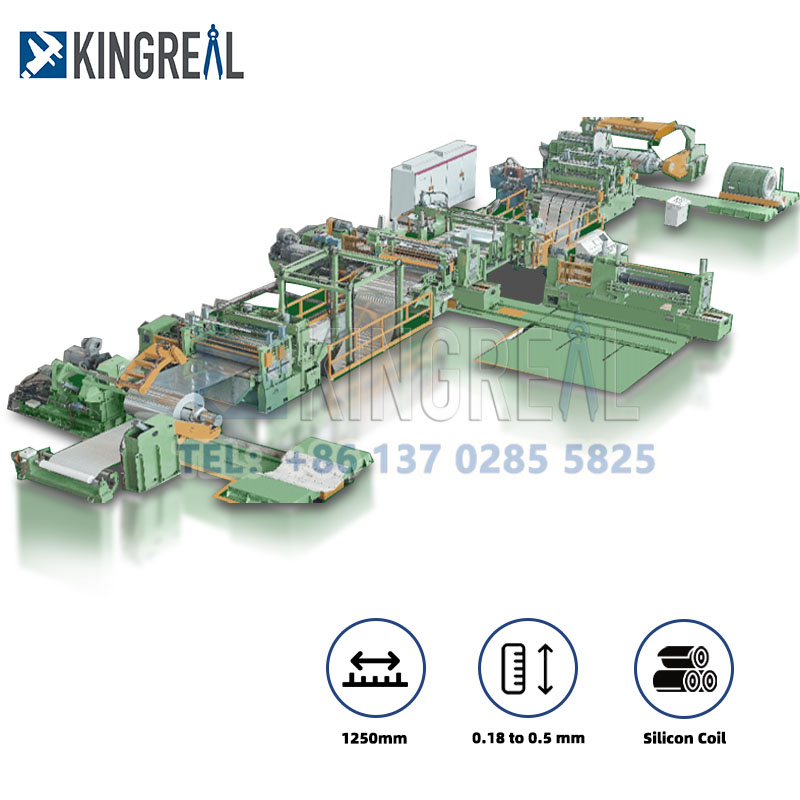

As an indispensable equipment in modern industrial production, silicon coil slitter is widely used in the processing of metal materials. Its main function is to slit large rolls of materials into small rolls of the required width, thereby improving production efficiency, ensuring slitting accuracy, and reducing the difficulty of subsequent processing.

Therefore, the excellent performance and long-term stable use of the silicon coil slitting line are directly related to the production efficiency and economic benefits of the factory.

Factors affecting service life of silicon coil slitting line

Material quality

The quality of materials used in the operation of the silicon coil slitting machine directly affects the degree of wear and damage risk of the machine. High-quality raw materials can reduce the wear of the tool and reduce the burden of the silicon coil slitting line, while inferior materials may cause the tool to wear too quickly and even cause machine failure.

Factory environment

The working environment of the silicon coil slitter also has an important impact on its service life. A humid, dusty or extreme temperature environment will accelerate the corrosion and aging of the silicon coil slitting machine and shorten its service life. Therefore, it is very important to keep the factory environment clean and at a suitable temperature and humidity.

Improper operation by workers

The skill level and operating specifications of the operator are also key factors affecting the service life of the silicon coil slitting line. If the worker has not received professional training, it may cause misoperation of the silicon coil slitting machine and damage to the equipment. In addition, failure to regularly maintain and inspect the silicon coil slitting machine in accordance with the operating procedures will also accelerate its wear and tear.

Usage and maintenance tips of silicon coil slitter

1. Regularly inspect silicon coil slitting line: Regularly conducting a comprehensive inspection of the silicon coil slitting machine is the key to ensuring its normal operation. The inspection content includes the wear of the tool, the lubrication status of the mechanical parts, the safety of the electrical system, etc. By discovering potential problems early, small faults can be avoided from turning into major faults, thereby extending the life of the silicon coil slitting machine.

2. Regularly maintain silicon coil slitting machine: Regular maintenance of the silicon coil slitting line should include cleaning, lubrication and replacement of worn parts. In particular, key components such as tools and bearings need to be replaced and maintained regularly to ensure their accuracy and performance. In addition, the establishment of maintenance records also helps to track the use and maintenance history of the silicon coil slitting machine.

3. Timely adjust the tool: The adjustment and replacement of the tool is an important part of the maintenance of the silicon coil slitting line. The sharpness of the tool directly affects the quality and efficiency of the slitting. Regularly checking the sharpness of the tool and adjusting or replacing it in time as needed can effectively improve work efficiency and cutting quality.

KINGREAL SLITTING's Service

In order to solve various problems encountered by users in the use of silicon coil slitting machines, KINGREAL SLITTING provides comprehensive service support, including silicon coil slitting line maintenance and operation guidance.

1. Machine maintenance: KINGREAL SLITTING has a professional maintenance team that can provide fast and efficient maintenance services for various types of silicon coil slitting machine failures. Whether it is an electrical failure or a mechanical failure, professional technical support can be used to ensure the normal operation of the silicon coil slitting line.

2. Machine operation guidance: In order to improve the operating level of workers, KINGREAL SLITTING also provides professional training courses to guide workers on how to operate the silicon coil slitting machine correctly and safely. These trainings not only include basic operating procedures, but also cover maintenance techniques and troubleshooting methods, so that workers can better deal with problems in actual operations.

Through the above measures, the service life of the silicon coil slitting machine can be effectively extended, thereby providing more lasting support for the factory's production.