In modern manufacturing, stainless steel ctl line, as an important processing equipment, undertakes the task of accurately shearing metal coils according to the preset length of customers. This process not only involves the application of technology, but also concerns production efficiency and product quality. Stainless steel cut to length line is widely used in many fields such as automobile industry, industry, construction industry, aerospace industry, etc. Due to its flexibility and efficiency, it has become a key link in the production process of many enterprises.

In this article, KINGREAL SLITTING will discuss in detail the definition of stainless steel cut to length machine, market demand, and various methods to improve the efficiency of stainless steel cut to length line.

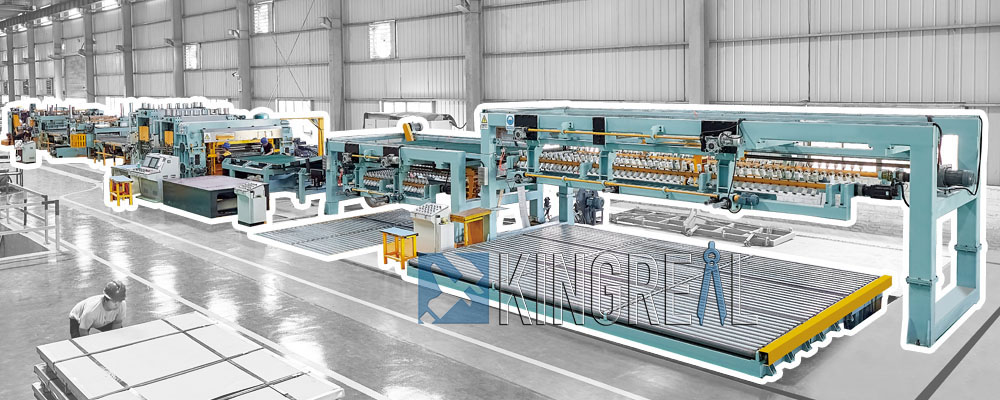

Introduction of stainless steel cut to length line

Stainless steel cut to length machine is a kind of equipment specially used for shearing metal coils (such as steel coils, aluminum coils, etc.). It uses advanced shearing technology to cut wide metal coils into the length and width required by customers, which is convenient for subsequent processing and manufacturing. Stainless steel ctl line usually consists of multiple parts, including feeding device, shearing device, winding device and control system.

The working process of stainless steel cut to length machine is as follows: the metal coil is fed into the shearing area through the feeding device, and after precise cutting, the product is wound or conveyed to the next process. This process requires high-precision control and stable equipment performance to ensure the quality of the final product.

Market demand for stainless steel ctl lines

With the rapid development of the global manufacturing industry, the market demand for stainless steel cut to length lines is increasing. Here are some major countries and the reasons for their demand:

1. China

As the world's largest manufacturing country, China's industry is developing rapidly. The huge demand for metal materials in industries such as automobiles, construction, and home appliances has promoted the widespread application of stainless steel cut to length machines.

2. The United States

The United States is very mature in fields such as aerospace, automobiles, and construction, and the demand for high-quality metal processing continues to grow. Shearing lines play a key role in these industries and can improve production efficiency and product accuracy.

3. Germany

Germany is famous for its high-end manufacturing industry, especially in the automotive and mechanical engineering fields. As the demand for customized and high-quality products increases, the demand for stainless steel cut to length lines also rises.

4. Japan

Japan's manufacturing industry is known for precision processing, and stainless steel cut to length machines play an important role in its electronics, automobiles, and machinery industries. Efficient shearing technology can meet the demand for high precision and high efficiency.

5. India

With the acceleration of industrialization, India's demand for metal processing equipment is increasing. The demand for stainless steel cut to length machines in the automotive, construction and heavy industry fields is also rising.

6. South Korea

South Korea's manufacturing industry is also developing rapidly, especially in the fields of electronics and automobile manufacturing. The high efficiency and flexibility of stainless steel cut to length lines make it the first choice for many companies.

Methods to improve the efficiency of stainless steel ctl lines

Improving the efficiency of stainless steel cut to length machines can not only reduce production costs, but also improve product quality and market competitiveness. Here are some effective methods:

1. Choose the best configuration

Different types of stainless steel cut to length lines differ in shearing methods and speeds. Among them, flying shear technology is widely used. Flying shears have the characteristics of non-stop shearing, and their shearing speed can reach 80m/min, which significantly improves production efficiency. In addition, it is also crucial to select suitable shearing tools and materials to ensure that they have good wear resistance and cutting performance.

2. Implementing an automated control system

The introduction of an automated control system can significantly improve the efficiency of stainless steel cut to length machines. Through PLC (Programmable Logic Controller) and HMI (Human Machine Interface) technology, real-time monitoring and adjustment of the shearing process can be achieved, and problems can be discovered and solved in time. In addition, the automation system can also reduce manual intervention and improve production stability.

3. Regular maintenance and care

The normal operation of the equipment is inseparable from regular maintenance and care. Formulating a detailed maintenance plan, including regular inspection of the wear of the tool and the working status of the lubrication system, can effectively extend the service life of the equipment and reduce the failure rate. Ensuring that the equipment is in the best condition can greatly improve production efficiency.

4. Optimizing the production process

Optimizing the production process of the stainless steel cut to length line can improve the overall work efficiency. By reasonably arranging the order of feeding, shearing and winding, and reducing the waiting time between each link, the production efficiency can be effectively improved. In addition, the use of advanced logistics systems combines material transportation with the shearing process to reduce the material handling time.

5. Strengthening personnel training

Operators are an important guarantee for the efficient operation of the stainless steel cut to length line. Regular training of operators to improve their equipment operation skills and troubleshooting capabilities can reduce operating errors and ensure the smoothness of the production process. In addition, strengthen safety training to ensure that operators can work efficiently in a safe environment.

6. Data monitoring and analysis

By monitoring and analyzing the operating data of the stainless steel cut to length machine, potential problems can be discovered in time. Collect data such as shearing speed, equipment load, and failure rate, use data analysis tools to analyze, find out the key factors affecting production efficiency, and make targeted improvements.

7. Use high-quality raw materials

The quality of raw materials directly affects the working efficiency and product quality of the stainless steel cut to length line. Selecting high-quality metal coils can ensure the smooth progress of the shearing process and reduce downtime caused by material problems. At the same time, high-quality raw materials can also enhance the market competitiveness of the final product.

8. Use advanced technology

With the advancement of science and technology, many new technologies are constantly emerging, such as laser shearing and plasma shearing. Although the initial investment of these technologies is relatively high, their high efficiency and high precision can significantly reduce costs and improve production efficiency in long-term operations. Enterprises should choose suitable advanced technologies for application according to their own conditions and market demand.

9. Implement lean production

Lean production is a management concept aimed at eliminating waste and improving efficiency. By optimizing the production process and reducing unnecessary links and resource waste, the efficiency of the stainless steel cut to length machine can be effectively improved. The implementation of lean production requires the participation of all employees, from management to front-line employees, to form a good production atmosphere.

10. Feedback mechanism

Establishing an effective feedback mechanism and timely collecting opinions and suggestions from operators and quality inspectors can help companies identify problems in production and make targeted improvements. Through regular feedback meetings, sharing experiences and lessons, the operating efficiency of the stainless steel cut to length machine can be continuously optimized.