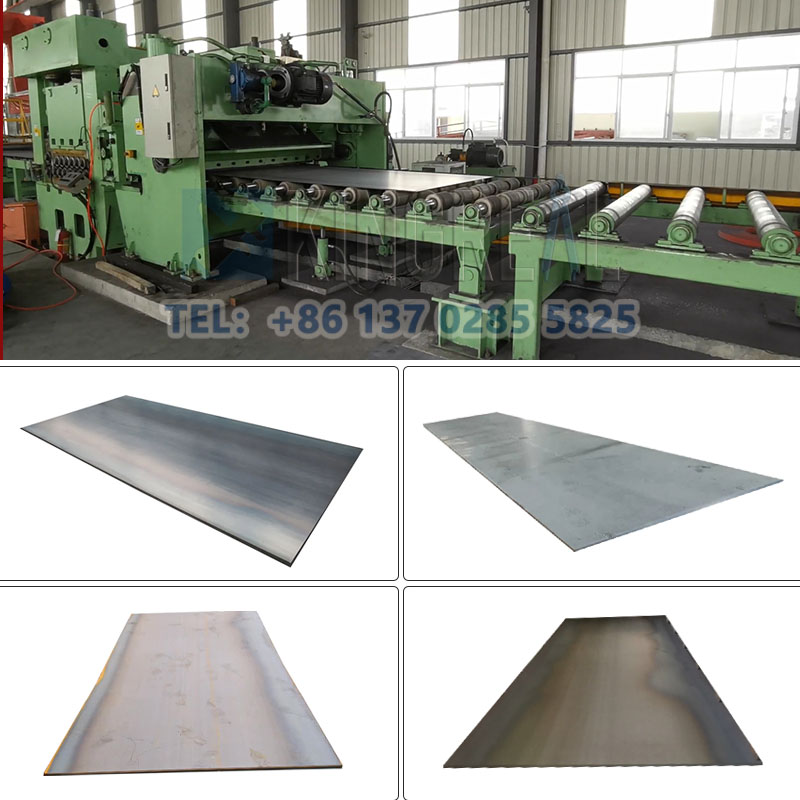

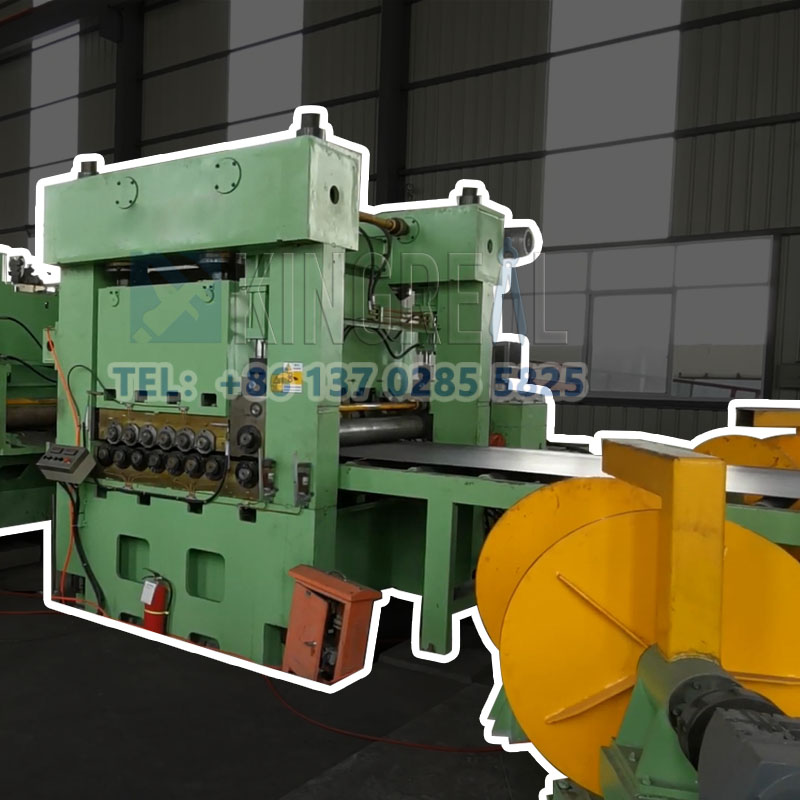

In modern manufacturing, heavy gauge cut to length lines, as an important metal processing equipment, are widely used in the shearing and slitting of steel, aluminum and other metal materials. With the acceleration of industrialization, the market demand for heavy gauge cut to length machines continues to increase, and its importance in factory production has become increasingly prominent. The normal operation of heavy gauge ctl lines not only affects production efficiency, but is also directly related to production costs and product quality.

However, once the heavy gauge cut to length line fails, the factory will face serious losses, including production delays, downtime losses, and repair costs. Therefore, improving the service life of heavy gauge ctl lines and reducing equipment failure rates have become the focus of major manufacturing companies. In this article, KINGREAL SLITTING will discuss with you the factors that affect the life of heavy gauge cut to length machines, as well as effective methods to improve the service life of heavy gauge ctl lines, so as to help companies improve their return on investment.

1. Factors affecting the life of heavy gauge ctl lines

1.1 Daily maintenance

Daily maintenance is the basis for ensuring the normal operation of heavy gauge cut to length machines. Lack of regular maintenance and care will lead to increased wear and tear of equipment and shorten its service life. Here are a few key points to note in daily maintenance:

✦ Lubrication system: The lubrication system of the heavy gauge cut to length line is essential to prevent wear and overheating. Check the quality and oil level of the lubricating oil regularly to ensure that all moving parts are fully lubricated.

✦ Cleaning work: During the production process, metal chips and dirt will accumulate inside the equipment, affecting the normal operation of the equipment. Regularly cleaning up the debris inside and around the equipment and keeping the equipment clean can effectively extend its service life.

1.2 Operating specifications

The operating habits and skill level of the operator directly affect the service life of the heavy gauge cut to length machine. Improper operation may cause excessive wear and failure of the equipment. Operating specifications include:

✦ Training and assessment: Provide professional training for operators to ensure that they understand the operating procedures and precautions of the equipment and reduce operating errors.

✦ Follow equipment instructions: Operators should strictly follow the operating manual provided by the equipment manufacturer to avoid overload and improper operation.

1.3 Material quality

The quality of the metal materials used is also an important factor affecting the life of the heavy gauge ctl line. Low-quality raw materials may cause increased wear of the equipment and increase the risk of failure. Selecting the right material and ensuring that it meets the processing standards is the key to extending the service life of the heavy gauge cut to length machine.

1.4 Environmental factors

The working environment of the heavy gauge ctl line will also affect its service life. Harsh environments such as high temperature, high humidity, and dust may cause corrosion and failure of the equipment. Therefore, maintaining a good working environment and regularly checking the external conditions of the equipment can effectively prevent the impact of environmental factors on the equipment.

1.5 Equipment design and manufacturing quality

The design and manufacturing quality of the heavy gauge cut to length machine are directly related to its service life. High-quality equipment usually uses high-quality materials and advanced technology, and has better wear resistance and stability. Therefore, choosing heavy gauge cut to length lines produced by well-known brands and manufacturers is an important guarantee for extending the service life.

2. Methods to improve the life of the heavy gauge ctl line

In order to effectively improve the service life of the heavy gauge cut to length machine, KINGREAL SLITTING recommends that enterprises can take the following methods:

2.1 Correct use of the machine

When using the heavy gauge cut to length machine, operators should follow the following principles:

✦ Reasonable arrangement of production plan: avoid the equipment being in full load for a long time, reasonably arrange production tasks, and leave enough rest and cooling time for the equipment.

✦ Control cutting speed and pressure: adjust the cutting speed and pressure according to the characteristics of the material to avoid excessive wear and damage to the tool.

2.2 Regular maintenance

Regular maintenance is a key measure to increase the service life of heavy gauge ctl line. Enterprises should develop a detailed maintenance plan, including:

✦ Regular inspection: Regularly conduct a comprehensive inspection of the equipment to promptly detect and solve potential problems. The inspection content includes electrical systems, hydraulic systems, mechanical parts, etc.

✦ Replacement of worn parts: For easily worn parts, such as knives and bearings, regular replacement is carried out to ensure the normal operation of the equipment.

2.3 Strengthen employee training

Enterprises should attach importance to employee training, regularly organize technical training and skill improvement courses, so that employees can master the operation essentials and maintenance knowledge of the heavy gauge ctl line. Strengthen employees' sense of responsibility and safety awareness to reduce equipment damage caused by improper operation.

2.4 Use high-quality materials

During the shearing and slitting process, choosing high-quality metal materials can reduce wear on the equipment and increase the service life of the heavy gauge ctl line. Enterprises should cooperate with reliable suppliers to ensure the quality of raw materials.

2.5 Regular technical transformation

With the advancement of technology, enterprises can consider appropriate technical transformation of equipment. For example, installing advanced monitoring systems to monitor the working status of equipment in real time and detect abnormal conditions in time can effectively reduce the occurrence of failures.

2.6 Improve environmental adaptability

Creating a good working environment for theheavy gauge ctl line can effectively extend its service life. Enterprises can take the following measures:

✦ Control temperature and humidity: Maintain the appropriate temperature and humidity in the workshop to prevent equipment from being damaged by environmental factors.

✦ Dust prevention measures: Set up dust prevention facilities in the workshop to reduce dust damage to the equipment and ensure the normal operation of the equipment.

2.7 Establish equipment files

Establish detailed equipment files for each heavy gauge cut to length machine to record the operation status, maintenance history and fault records of the equipment. By analyzing these data, enterprises can discover the usage patterns of the equipment and take corresponding maintenance and care measures in a timely manner.