Definition of metal cut to length machine

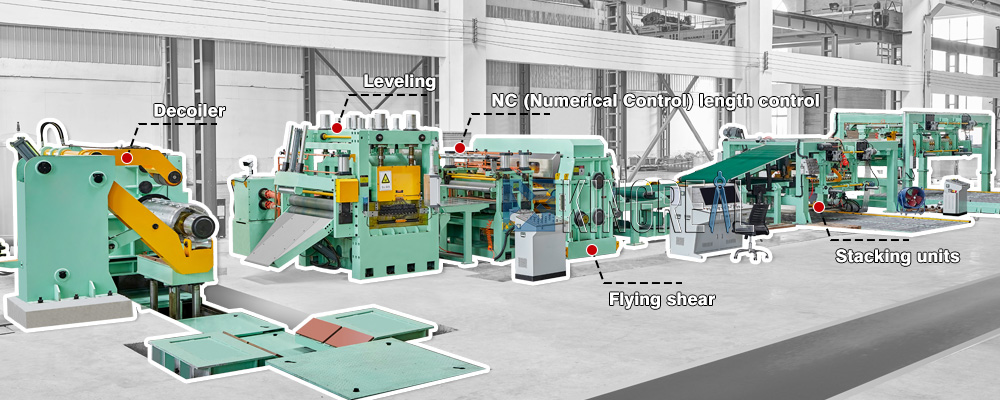

Metal cut to length equipment is an automated production equipment used to accurately cut metal coils or metal sheets. It is widely used in the production of many industries such as steel, machinery, construction, automobiles, and home appliances.Its main function is to shear large coils of metal materials into sheets that meet the size requirements. These sheets are usually used as raw materials in subsequent processing. Cut to length equipments play an important role in improving production efficiency, ensuring product quality, and reducing labor costs. They are one of the indispensable equipment in modern manufacturing.Metal cut to length machines usually consist of multiple functional modules, including feeding systems, leveling devices, shearing equipment, receiving systems, and control systems. First, the metal coil is fed into the shearing line through the feeding device, and the coil is leveled by the precision straightening machine to eliminate the curling and warping of the coil and ensure the flatness of the sheet.

The leveled metal sheet is cut by a high-precision shearing system, and the shearing accuracy and speed can be adjusted according to customer needs. The sheared sheets are collected and stacked by the receiving system to facilitate subsequent processing or transportation.

KINGREAL SLITTING newly design: simple metal cut to length machine

In the metal sheet processing industry, improving production efficiency and reducing production costs have always been the goal pursued by factories. In order to meet the needs of factories with low production requirements,KINGREAL SLITTING recently launched a newly designed "simple metal cut to length machine", which has excellent machine advantages and can help factories reduce production costs and improve production efficiency.

Compared with other high-end metal cut to length equipment, this simple cut to length machine is more prominent in terms of machine advantages.

First of all, the price of the machine is more affordable, suitable for factories with low production requirements, reducing the burden of equipment investment.

Secondly, the maintenance cost of the cut to length equipment is also low, and it does not require too much manpower investment, which further reduces the production cost. In addition, the equipment occupies a small area, saving the factory's space resources.

KINGREAL SLITTING simple cut to length machine consists of four parts: unwinding, leveling, shearing, and stacking, which can meet the basic production needs of customers. And the machine is compatible with a variety of metal raw materials, such as chrome steel, galvanized iron sheet, galvanized aluminum sheet, etc. The production speed can be adjusted by itself, up to 30m/min.

The cut to length equipment adopts advanced automation technology to achieve metal sheet cutting. Compared with the traditional shearing process, the equipment reduces the need for manual operation and greatly improves production efficiency. At the same time, the cut to length equipment also has an intelligent control system that can accurately control the cutting size and ensure the stability of product quality.

KINGREAL SLITTING customized service

KINGREAL SLITTING always adheres to the service concept of "customer first". With rich industry experience and advanced technology, different cut to length equipment solutions are tailored to the specific needs of customers. KINGREAL SLITTING is well aware that each customer's production environment, processing requirements and quality standards are different.

Therefore, KINGREAL SLITTING's engineering team will provide one-to-one customized solutions based on the actual needs of customers to ensure that the metal cut to length machine can not only operate efficiently, but also accurately match the customer's production goals.

In addition to the simple metal cut to length machine, KINGREAL SLITTING has also launched the following according to customer needs:

● Heavy duty metal cut to length machines that can handle metal coils with a maximum thickness of 25mm,

● Flying shearing metal cut to length machines that can be produced at high speed and have a maximum speed of 80m/min,

● Metal cut to length machines equipped with dual precision straightening machines designed for customers with high requirements for plate flatness, etc.

In addition to the existing standard cut to length equipment and customized solutions, KINGREAL SLITTING continues to develop and launch more innovative cut to length equipment based on market demand and customer feedback.

KINGREAL SLITTING’s team always remains sensitive to industry trends and keeps up with the pace of technological innovation. Therefore, no matter what special needs you have, KINGREAL SLITTING can provide you with a tailor-made metal cut to length machine solution.KINGREAL SLITTING is well aware that with the rapid development of the manufacturing industry, customers' demand for equipment is becoming more and more personalized and professional.KINGREAL SLITTING is good at designing and manufacturing unique equipment that is not available on the market according to industry characteristics and customer-specific requirements to meet the needs of different industries. Whether it is special shearing thickness, ultra-high speed, precision, or shearing of special materials, KINGREAL SLITTING is the ability to provide customers with exclusive innovative solutions.