Cold rolled cut to length line is a kind of equipment specially used to cut metal coils into the length required by customers for subsequent processing. This kind of equipment plays a vital role in the metal processing industry and is widely used in many fields. In this article, KINGREAL SLITTING will discuss in detail the definition, application field, market demand and advantages of cr cut to length line.

Definition of cr cut to length line

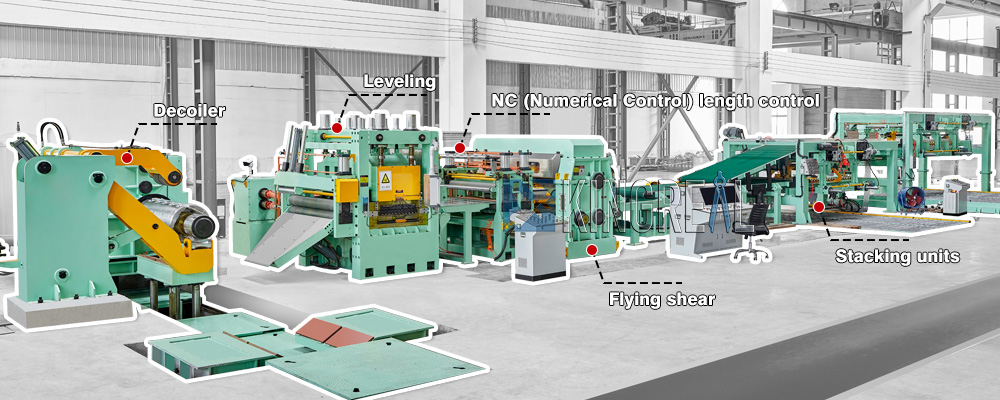

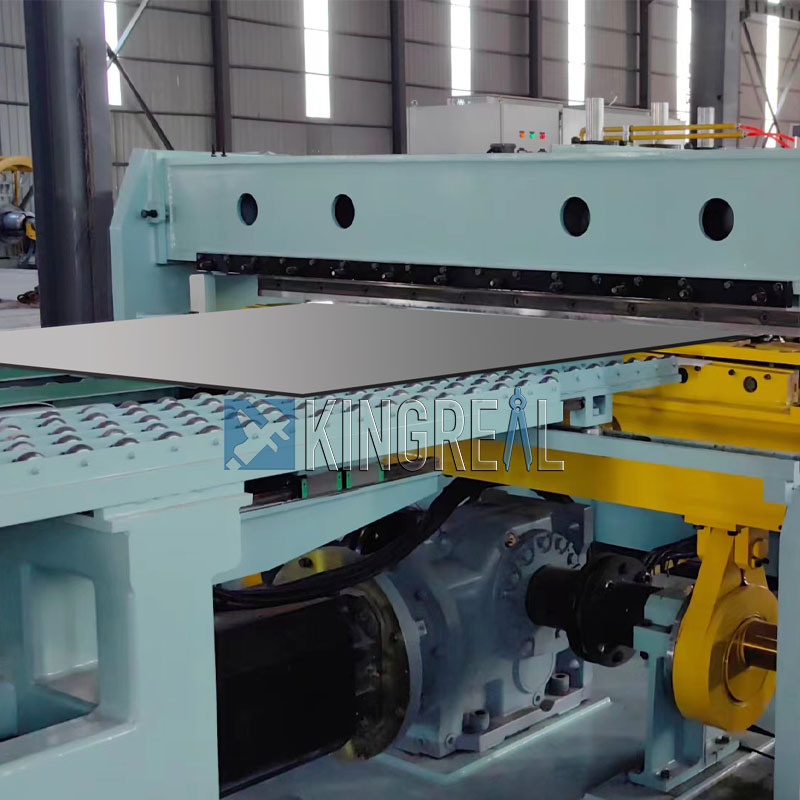

Cold rolled cut to length machine is an automated production equipment, which is mainly used to cut metal coils into metal sheets of specified length according to customer requirements. Its working process usually includes several links such as uncoiling, leveling, and shearing. Through these links, the cold rolled cut to length line can efficiently and accurately process the coils into standard products for subsequent processing and application.

The high efficiency and automation of the cold rolled cut to length machine make it an indispensable equipment in modern manufacturing. It can not only improve production efficiency, but also reduce labor costs, improve product processing accuracy, and bring significant economic benefits to enterprises.

Application fields of cr cut to length lines

CR cut to length lines are widely used in many industries. Here are some of the main application fields:

1. Electronics industry

In the electronics industry, cold rolled cut to length machines are mainly used to process electronic components and housings. Precise shearing and high-quality metal materials are essential to the performance and appearance of electronic products. Using cold rolled cut to length lines, companies can quickly produce metal sheets that meet specifications to meet the needs of different types of electronic products.

2. Aerospace

The aerospace industry has extremely high requirements for the quality and performance of metal materials, and cold rolled cut to length machines also play an important role in this field. By using high-precision cold rolled cut to length line, companies can ensure the production of metal sheets that meet aviation standards, which is essential for the manufacture of complex products such as aircraft and spacecraft.

3. Construction industry

In the construction industry, cr cut to length lines are widely used to process metal materials for construction, such as steel plates, aluminum plates, etc. These materials are often used in building structures, decoration and infrastructure. Cold rolled cut to length machines can quickly and efficiently produce the required metal sheets according to the needs of architectural design to ensure the smooth progress of construction.

4. Automobile Manufacturing

The automobile manufacturing industry has strict requirements on the precision and strength of metal parts. Cold rolled cut to length lines can efficiently process various metal materials required for automobiles, including body, chassis and other structural parts. Through precise shearing, enterprises can improve production efficiency and reduce material waste.

5. Home Appliance Industry

In the home appliance industry, cr cut to length lines are mainly used to process shells and internal structural parts. High-quality metal materials and precise shearing can ensure the safety and aesthetics of home appliance products. As the home appliance market continues to expand, the application of cold rolled cut to length machines is also increasing.

Market demand for cold rolled cut to length lines

With the continuous advancement of global industrialization, the market demand for cold rolled cut to length machines has gradually increased. The following are some countries with large demand for cr cut to length lines and the reasons:

1. China

China is the world's largest manufacturing country, and the demand for cold rolled cut to length machines is extremely large. With the acceleration of urbanization and the advancement of infrastructure construction, the rapid development of the construction industry, automobile manufacturing industry and electronics industry have all driven the demand for cold rolled cut to length lines. In addition, China has an increasing demand for efficient and automated production equipment to improve production efficiency and reduce labor costs.

2. United States

The US manufacturing industry also has a strong demand for cold rolled cut to length machines. With the advancement of Industry 4.0, the traditional manufacturing industry is transforming towards intelligence and automation. As an efficient automation equipment, cr cut to length lines help American companies maintain their competitiveness in the fierce market competition and have become a popular choice in the market.

3. Germany

Germany is famous for its high-quality manufacturing industry, and cold rolled cut to length lines play an important role in Germany's industrial production. German companies have extremely high requirements for the accuracy and reliability of equipment, and the efficiency and precision of cr cut to length lines just meet this demand. In addition, Germany's strong strength in aerospace and automobile manufacturing has also promoted the market demand for cold rolled cut to length lines.

4. Japan

Japan has a strong market demand in the fields of electronics and automobile manufacturing. With the continuous advancement of technology, the application of cr cut to length lines has gradually deepened and has become an indispensable production equipment in these industries. While pursuing high efficiency and high quality, Japanese companies have also put forward higher requirements for the degree of automation of equipment.

5. India

India's manufacturing industry is developing rapidly, especially in the automotive and construction industries, and the demand for cold rolled cut to length lines is gradually increasing. The government's emphasis on infrastructure construction and the rise of the manufacturing industry have made metal shearing lines an important equipment to promote economic growth.

Advantages of cr cut to length lines

The advantages of cold rolled cut to length machines have made them occupy a place in the market. The following are the main advantages of cold rolled cut to length lines:

1. Processing of metal sheets of various thickness

CR cut to length lines can process metal sheets of different thicknesses. In order to better meet market demand, KINGREAL SLITTING has designed three cold rolled cut to length lines for different metal thicknesses:

- Light gauge cut to length line: It can process metal sheets with a thickness of 0.3-3mm, suitable for the shearing of light metal materials.

- Medium gauge cut to length line:It can process metal sheets with a thickness of 0.3-6mm, suitable for medium thickness metal processing.

- Heavy gauge cut to length line: It can process metal sheets with a thickness of 6-20mm, suitable for the shearing of heavy metal structures.

This design of cold rolled cut to length lines for different thicknesses enables enterprises to choose suitable equipment according to their own needs, improving the flexibility and efficiency of production.

2. Fast shearing speed

The cr cut to length line has high working efficiency and the shearing speed can reach up to 80m/min. This high-speed shearing capability enables enterprises to complete a large number of orders in a short time, greatly improving production efficiency. In an environment of increasingly fierce market competition, fast production capacity has won more market opportunities for enterprises.

3. Customization

KINGREAL SLITTING is committed to meeting the needs of different customers and providing a variety of customized cold rolled cut to length machine designs. For example, KINGREAL SLITTING has designed a cr cut to length line with lamination, a cold rolled cut to length line with double levelers, and a cold rolled cut to length line with double stackers. This flexible customization service enables customers to choose the most suitable equipment according to their own production requirements and market demand, thereby improving production efficiency and product quality.

Not only that, in response to the special needs of customers, KINGREAL SLITTING also welcomes customers to provide drawings for customization. This personalized service enhances customer satisfaction.

4. Different shearing speeds

According to different production situations of customers, KINGREAL SLITTING has designed three cr cut to length lines with different shearing methods:

- Flying shear cut to length line:suitable for fast shearing, which can meet efficient production needs.

- Fixed shear cut to length line: suitable for conventional production, which can provide stable shearing quality.

- Swing shear cut to length line: suitable for shearing of complex shapes, which can meet diversified product needs.

This diversified shearing method enables enterprises to choose the most suitable equipment according to their own production methods and product needs, which improves production flexibility.