Rotary shearing ctl machine is an automated equipment for metal sheet processing, which is designed to shear metal coils into flat sheets of specific lengths. It is mainly used for shearing a variety of metal materials such as cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, etc. The basic composition of the rotary shearing cut to length machine includes a loading trolley, an decoiler, a leveler, a feeding mechanism, a shearing machine, a conveying device and a stacking device, etc., which can efficiently complete the cross-cutting operation of metal materials.

Rotary shearing ctl line produces flat sheets of the required length by uncoiling, leveling, sizing and shearing the metal coils. With the advancement of science and technology and the increase in industrial demand, the functions and application scope of the rotary shearing cut to length machine are constantly expanding. This article will discuss in detail the working principle, main advantages and application areas of the rotary shearing cut to length machine around the world.

1.Working principle of the rotary shearing ctl line

The working principle of the rotary shearing ctl machine is mainly based on the principles of mechanical shearing and material deformation. Its basic process includes the following steps:

1. Uncoiling: Under the action of the decoiler, the metal coil is unfolded and prepared for subsequent processing.

2. Leveling: The leveling machine bends and stretches the plate several times to make its surface flat and eliminate internal stress. This process is crucial to ensure the quality of the final product.

3. Feeding: The leveled plate is accurately fed into the shearing machine through the feeding mechanism to ensure accuracy during the shearing process.

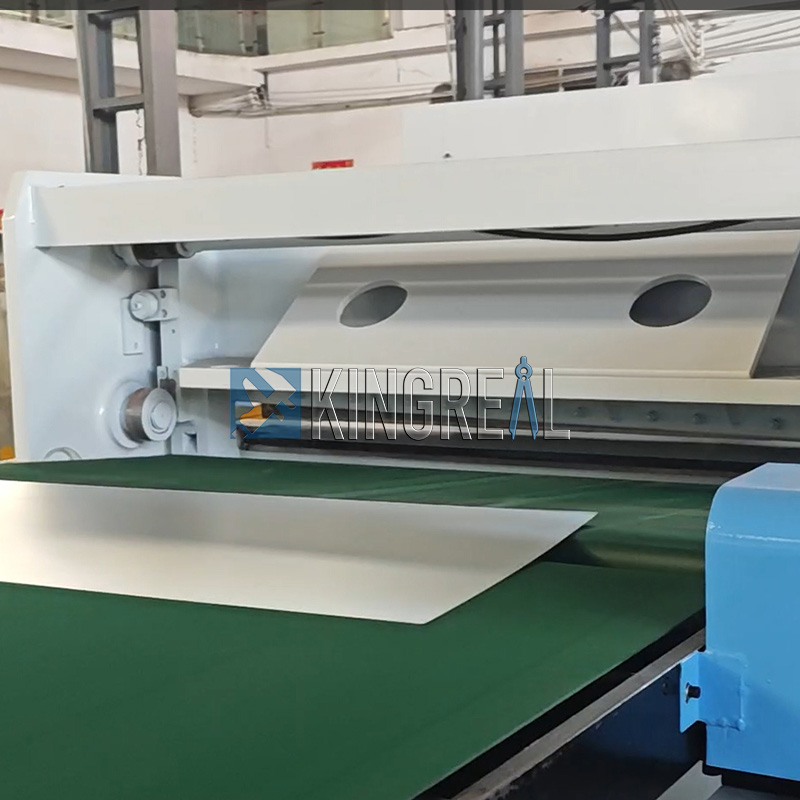

4. Shearing: The shearing machine shears according to the set length to ensure that the size of each plate is accurate and the edges are smooth.

5. Conveying and stacking: After shearing, the plate is sent to the stacking device through the conveying device and neatly stacked for subsequent processing and transportation.

This series of work processes ensures the efficiency and accuracy of the rotary shearing cut to length machine, making it play an important role in the metal processing industry.

2. Advantages of the rotary shearing ctl line

The design and function of the rotary shearing cut to length machine give it many significant advantages, which make it widely used in the field of metal processing.

2.1 High precision

The rotary shearing ctl line can achieve high-precision shearing through advanced mechanical design and automated control. Specifically:

- No scratches: During the shearing process, the design of the equipment can effectively avoid scratches on the surface of the material and ensure the surface quality of the final product.

- No burrs: Modern rotary shearing cut to length machines use precise tool design, which can reduce the generation of burrs during shearing and improve the quality of material use.

High-precision shearing enables enterprises to produce products that meet strict quality standards, thereby enhancing market competitiveness.

2.2 Full automation

The full automation of the rotary shearing ctl line is one of its major advantages. Operators can set parameters such as shearing speed and shearing length according to production requirements, and the equipment will automatically complete the shearing process. The advantages of this automation are reflected in:

- Reduce labor costs: Fully automated operation reduces manual intervention, and enterprises can effectively reduce labor costs.

- Improve production efficiency: The equipment can run continuously for a long time without being affected by fatigue, ensuring stable production efficiency.

- Easy operation: The modern rotary shearing cut to length machine has a friendly operating interface, and the time required to train new employees is short, which reduces the difficulty of operation.

2.3 Customization

With the diversification of market demand, customized rotary shearing ctl lines have become a trend. Rotary shearing ctl machines can be customized according to the actual production needs of customers to ensure the best match between equipment and production processes. Specifically, the advantages of customization include:

- Strong targeting: Different rotary shearing ctl line parameters are designed according to the specific production needs of customers. For example, the rotary shearing cut to length machine with double levers can achieve higher flatness through the design of two levelers; the heavy gauge rotary shearing ctl line can handle metal plates with a thickness of 6-20mm to meet the needs of heavy-duty industries; the rotary shearing cut to length machine with double stacking table increases the stacking speed, saves manpower, and avoids the risk of injury during handling.

- Market adaptability: Customized rotary shearing ctl machines can better adapt to market changes and improve the flexibility of enterprises.

2.4 Cost-effectiveness

Although the initial investment of rotary shearing ctl lines is high, its cost-effectiveness is very significant in the long run. Specifically include:

- High production capacity: The efficient operation of the rotary shearing ctl line can complete a large number of shearing tasks in a short time, thereby increasing overall production capacity.

- Save labor costs: With the increase in labor costs, the use of rotary shearing cut to length machines can effectively reduce long-term labor expenses and improve the return on investment.

- Equipment durability: Modern rotary shearing ctl lines are usually manufactured with high-quality materials and advanced technology, with long service life and low maintenance costs.

3. Application areas of rotary shearing ctl machines

Rotary shearing ctl machines are widely used around the world, covering multiple industries and countries. Here are some of the main application areas:

3.1 Construction industry

In the construction industry, metal materials are widely used in structural support, exterior wall decoration, roofing materials, etc. rotary shearing cut to length machines can provide high-precision metal sheets to meet the strict requirements of the construction industry for material quality.

3.2 Automobile manufacturing

A large amount of metal sheets are required in the automobile manufacturing process for the production of body, chassis and other parts. The efficient shearing and precise size of the rotary shearing ctl machine ensure the quality and safety of automobile parts.

3.3 Home appliance industry

The outer shell and internal structure of home appliance products usually require sheared metal materials. Rotary shearing ctl machines can quickly produce standard metal sheets to meet the needs of the home appliance industry.

3.4 Machinery manufacturing

The manufacture of various types of mechanical equipment requires metal sheets for shells, frames and parts. The wide application of rotary shearing ctl machines makes machinery manufacturing more efficient.

3.5 Shipbuilding

The manufacture of the hull structure and its internal equipment requires a large amount of metal plates. Rotary shearing ctl machines can meet the material needs of shipbuilding and ensure the safety and performance of ships.