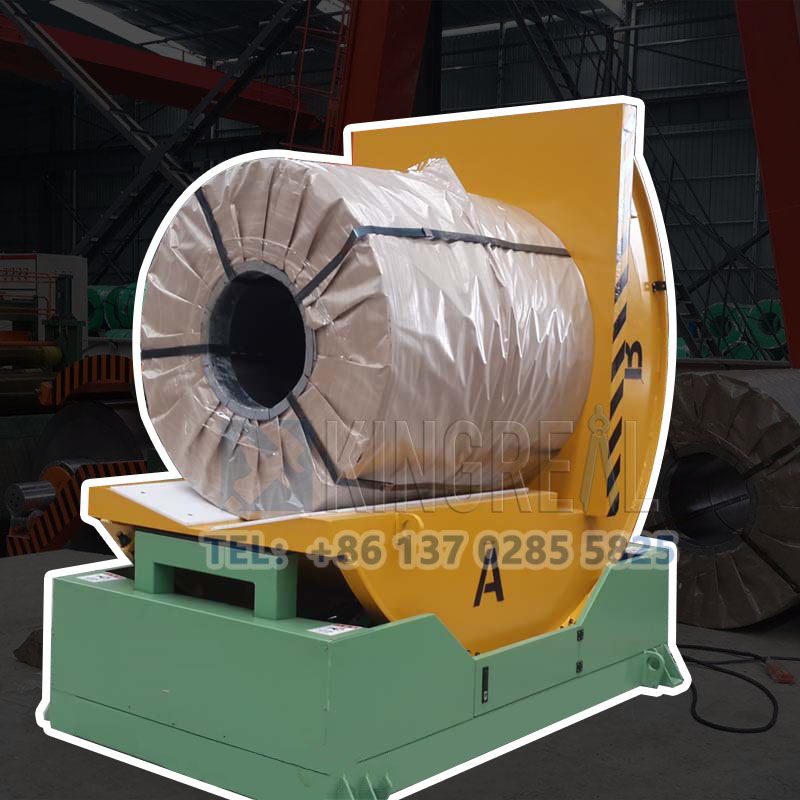

Description of Hydraulic Coil Tilter

KINGREAL SLITTING Coil turnover machine can accurately control the tilt angle of the coil to ensure a smooth transition and feeding of the coil into the coil slitter, the maximum tilt angle can reach 180°.

KINGREAL SLITTING coil upender and tilter has a fast flipping speed, which can reach 40-70 seconds/direction. The hydraulic coil tilter is mechanically driven and can stop and hold the load at any point during the rotation. KINGREAL SLITTING coil turnover machine is designed to simplify for customers the dangerous process of tilting coils manually or using a crane.

Parameters Of Coil Tipper

◆Load : 15T

◆OD: 800mm-1500mm

◆ID:508-610mm

◆Degree of tilting: 180°

◆Turn over speed 40-70 sec/direction

Main Components of Coil Upender and Tilter

◆Adjustable narrow coil support arms

◆Solid v-nest for coil support

◆180 degree rotating base

◆Guide rollers support

◆Powered sliding v-nest for skid removal

◆Heavy duty fabricated steel construction

Features of Coil Turnover Machine

① Fully automatic coil tilting.

The operation process of the coil upender and tilter is completely precisely controlled by the control panel. The operator only needs to input the flip angle, speed and other parameters in advance, and the hydraulic coil tilter can automatically perform the tilting operation according to the preset requirements. Through the digital control system, every detail can be accurately adjusted during operation to ensure stability and consistency during the tilting process. Automated coil tilting greatly improves production efficiency, while reducing errors in human operation, so that each tilt can achieve the best effect.

② Coil quality assurance.

Whether it is the internal and external structure of the coil or the surface state, the coil unpender can avoid damage caused by improper operation by precisely controlling the tilting angle and speed. Traditional manual operation or inaccurate automatic equipment may cause scratches, indentations and other damage to the coil surface, while KINGREAL SLITTING uses high-precision mechanical components and advanced control systems to ensure the stability and integrity of the coil throughout the tilting process, avoiding damage to the coil caused by misoperation, thereby protecting the quality of the coil and ensuring the flawlessness and high standards of the final product.

③ Adjustable flipping speed.

KINGREAL SLITTING coil turnover machine can flexibly adjust the flipping speed according to different production needs, and the fastest flipping speed can reach 70 seconds in one direction. This function is very suitable for customers who have different types of coil production needs. When processing heavier or thinner metal coils, different flipping speeds can be adjusted in time to ensure smooth tilting and no damage to the coils.

④ Position locking function.

The KINGREAL SLITTING coil tipper is equipped with a powerful position locking function, which can stop and maintain stability at any tilting angle. The position locking function of the coil turnover machine makes it convenient for workers to stop the machine at a specific angle for inspection, adjustment or subsequent processing.

⑤180° flipping.

Most Coil turnover machines on the market only support flipping the metal coil 90°, but KINGREAL SLITTING coil unpender can achieve 180° flipping and has more comprehensive functions.

Advantages Of Using With Coil Slitter

① Improve production safety. The use of coil upender and coil slitting machine can directly receive the coil and send it to the coil slitting line for processing through automatic metal coil tilting, avoiding errors or risks caused by manual handling. Through automated operation, reduce safety hazards during manual handling and operation.

② Efficient automated production line. The hydraulic coil tilter can work with the coil slitting machine to achieve high automation of the entire production process, thereby greatly improving production efficiency. Through the integration of the coil upender and the coil slitting machine, each link in the production line can be quickly and seamlessly connected together.

③ Improve slitting accuracy. After the metal coil passes through the coil upender and tilter, it is in a suitable state, and the coil slitter can better slitting and reduce errors in the cutting process.

④ Reduce labor costs. The use of the automated hydraulic coil tilter in conjunction with the coil slitting machine reduces dependence on manual operation. By reducing manual handling and operation, enterprises can not only improve production efficiency, but also effectively reduce labor costs. Workers no longer need to spend a lot of time and energy on high-intensity handling work.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil