Video About Fly Shearing Cut To Length Machine

Cut To Length Machine With Fly Shearing System

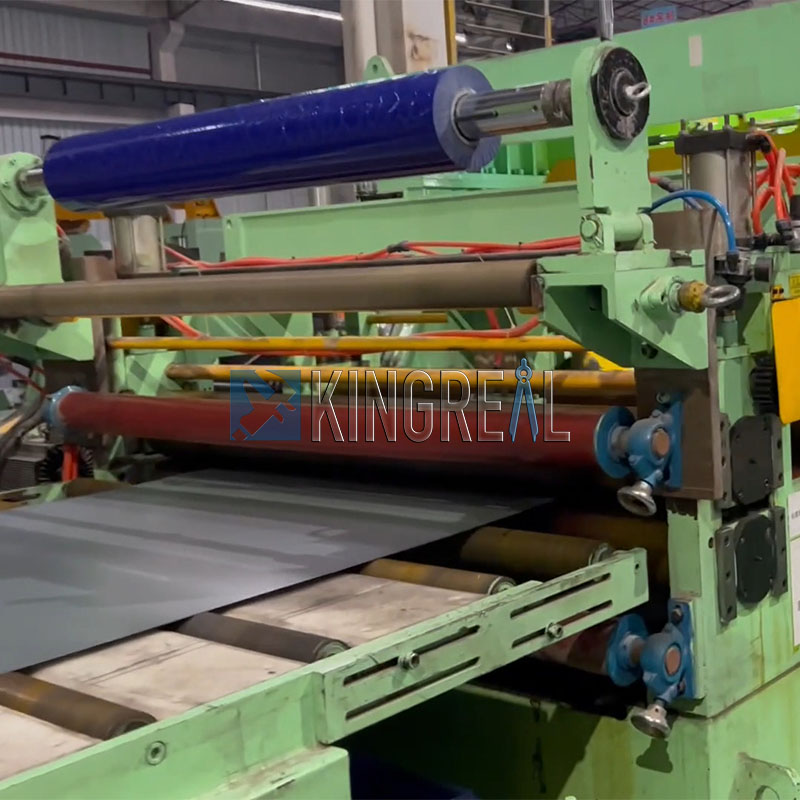

The Cut to Length Machine with Fly Shear is an industrial machine designed for cutting continuous metal strips into plates or sheets of specific lengths. KINGREAL SLITTING Fly Shearing technology enables continuous, automatic, and precise cutting of metal strips without stopping, even during high-speed movement, with speeds reaching up to 80 meters per minute. This machine is widely used in the processing of steel, aluminum, copper, and other metals, and finds applications in automotive, home appliances, construction, and other fields.

When the production line is in operation, the decoiler feeds the metal strips into the system. The sheet material first passes through a high-precision leveling machine with six layers and 21 rollers to ensure it is perfectly flat. Next, it enters the NC Length Measurer, which is controlled by an electric eye and lateral mechanism. The NC Length Measurer sets the desired length and then feeds the material to the rotary cutting machine. When the material reaches the set length, the shearing machine cuts the sheet, which is then neatly stacked by the conveying device into the Products Stacking Machine.

The lifting platform of the stacker automatically lowers as the height of the stacked steel sheets increases. Once the preset quantity of plates is reached, the production line automatically stops. At this point, the lifting platform is manually lowered, the discharge trolley is driven out, and another discharge trolley is driven in to begin the next working cycle.

Working Process Of High Speed Cut To Length Line

Material Upload → Automatic vertical Laser Centering → Pressing down material coil → Remove strap → Uncoiler feeding material → Pinch Rollers to enter the 6 layers precision Leveling Machine → Short Looper Station → Side Guide mechanism → Feeding-to-length → Fly Shearing Machine → Belt Conveying Device → Products Stacking → Discharging Trolley

Technical Specification

| 1 | Raw material | CRC STEEL |

| 2 | Thickness | 0.4-3.0mm |

| 3 | Width | ≤1500mm |

| 4 | Coil weight | ≤ 20T |

| 5 | Speed | 0~80m/min (Stepless speed regulation) |

| 6 | Power | 380V/50Hz/3Phase |

| 7 | Installed Capacit | Around 365KW |

| 8 | Control | AC frequency conversion control |

Feature Of Fly Shearing Cut To Length Line

1. According to the metal material, there are fixed-length stainless steel machines, silicon steel fixed-length machines, cold-rolled or hot-rolled plate fixed-length machines, etc.

2.Based on the control method, there are pneumatic cross-cutting lines, CNC cross-cutting lines, and more.

3. The main machine's bearings and slides are from imported brands, featuring an advanced lubrication system and ensuring long service life.

4. Electrical components are sourced from high-end imported brands, while mechanical parts come from renowned domestic and international brands.

5. Automatic switching of double palletizers ensures precise calculation, safety, and reliability. The system includes automatic detection and patting mechanisms.

6. The entire cut to length line is manufactured in strict accordance with mechanical standards, with rigorous tracking and control of each component's production. The machine is designed for a reasonable structure, compact form, high precision, high efficiency, and easy adjustments. Functions include automatic detection of steel coil parameters, one-key winding, one-key pick-up, and automatic alignment adjustment.

7. Collaboration with well-known manufacturers globally has introduced first-class leveling line technology. This technology is enhanced and expanded by our professional technical team to offer users high-quality, efficient automatic sheet processing equipment.

8. The line utilizes numerical control (NC) centralized control, providing three key advantages: high automation, high production efficiency, and high working precision.

FAQ :

1. What is the warranty period of your machines?

Our machine line provides 1 year warranty from the acceptance date of installation and commissioning.

2. How long will it take you to prepare the basic drawings for the machine line?

After receiving the 30% deposit, we need about 5 to 15 days to prepare the basic drawings for you.

3. What are your advantages?

Over 15 years of experience in machine manufacturing. Professional and experienced...

We are a manufacturer, not a trading company.

Therefore, we can provide strong and powerful pre-sales and after-sales services.

We can produce 4 lines per month

4. Do you have after-sales support?

Yes, we have a professional and strong installation team. And will provide you with lifetime service of the machine.

If you have any problem, please contact us and we will solve it for you.

5. How can I visit your company?

Our factory is located in Foshan City, near Guangzhou. Therefore, there are two ways to reach our factory.

One is to take a plane and go directly to Guangzhou or Foshan airport.

The other is to take a high speed train to Guangzhou or Foshan railway station.

We will pick you up at the railway station or the airport.

6. what information you need to prepare a quotation?

1. Coil thickness (min-max)

2. Coil width (min-max)

3. the type of material you have

4. the weight of your rolls (max)

5. How many tons do you need per day or per month?

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil