Definition of Cut to Length Line Machine

Cut to length line machine, also known as a coil cut to length machine or CTL, is designed to unroll and flatten steel coils, which are then cut to the desired width or length and back punched to achieve the final profile.Coil cut to length machine handling with wide coils is typically equipped with quick tool change systems to accommodate different cutting applications, uncoiler and back-flushers systems and collection systems to stack sheet products into bundles.High-performance slitters are used in fixed-coil cut to length machines, which are typically circular cutters that handle a variety of rolled metal coils and efficiently cut them to precision lengths.

KINGREAL SLITTING's experience in coil cut to length machine manufacturing

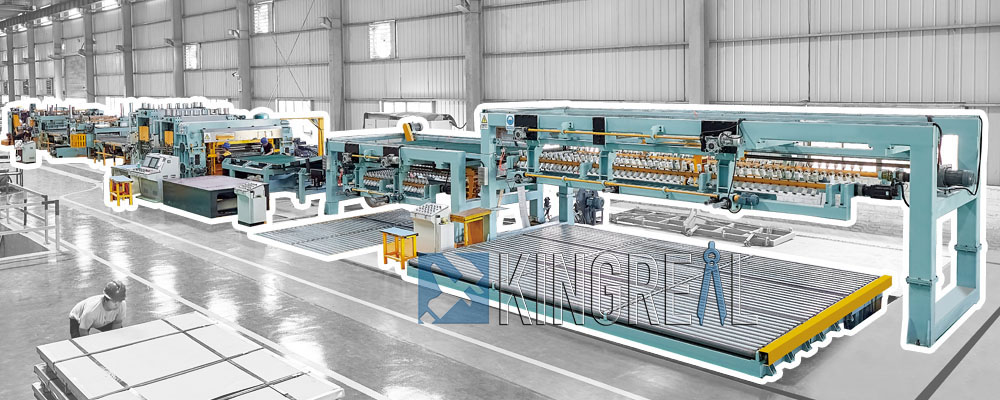

KINGREAL SLITTING has been deeply involved in the field of cut to length line machine manufacturing for more than 20 years. With its excellent technology and innovative design, its machine products have been exported to more than 20 countries and regions around the world, including Russia, India, Turkey, UAE and other important markets.

As a leader in the industry, KINGREAL SLITTING has an experienced and skilled team of engineers. The team can tailor cut to length line machine solutions according to the specific production needs of customers to ensure the efficiency and applicability of the equipment. In the manufacturing process of each cut to length line machine, KINGREAL SLITTING strictly controls every detail, from design, production to installation and commissioning, to ensure that the equipment can perfectly match the needs of customers.

Multiple coil cut to length machine solutions provided

Over the years, KINGREAL SLITTING has been expanding the models of coil cut to length machines according to market demand. KINGREAL SLITTING can provide a variety of different solutions for customers to choose from.Among them, the following models are KINGREAL SLITTING's special cut to length line machine models, which are loved and praised by many customers:

In order to maximize the production efficiency of customers, KINGREAL SLITTING engineers have configured a flying shearing station for the cut to length line machine. The flying shearing station can quickly and accurately cut metal plates, with a maximum cutting speed of 80m/min. Compared with traditional fixed shearing, the flying shearing station can perform continuous shearing without stopping, which makes its speed several times higher than that of fixed shears. The high efficiency of the flying shear greatly reduces the time waste in the shearing process and greatly improves the overall operating efficiency of the production line.

② Heavy Gauge cut to length line machine

For customers who need to process thicker metal raw materials, KINGREAL SLITTING has designed a dedicated heavy gauge cut to length line machine. Most cut to length line machines on the market can usually only process metal plates with a thickness of 0.3 to 3 mm, while KINGREAL SLITTING heavy gauge cut to length line machine can process metal materials with a thickness of up to 25 mm, meeting the needs of steel, machinery, shipbuilding, construction, petroleum, power and other industries for thick plate processing. The design of the heavy gauge cut to length line machine requires higher standards for the raw materials and processes of the machine manufacturing. KINGREAL SLITTING has specially optimized the structure of the equipment to ensure the precision shearing of high-thickness plates.

③ Dual Precision Straightening Machines

In order to meet customers' strict requirements for the straightness of metal plates, KINGREAL SLITTING has equipped the cut to length line machine with double straightening machines. Each precision straightener is equipped with 21 working rollers, 4 clamping rollers, 23 intermediate rollers and 5 sets of supporting upper and lower rollers. The double straightening machine ensures that the coils with rough and uneven surfaces can be finely leveled through two leveling processes. First, the metal coil is initially leveled by the first leveling machine, and then directly transported to the second leveling machine for further precision leveling. This double leveling system greatly improves the straightness of the metal plate, ensuring its quality after processing and stability in subsequent use.

KINGREAL SLITTING has equipped the cut to length line machine with a double stacker, which can simultaneously receive and store two sheared plates of different speeds or sizes, thereby effectively reducing the downtime waiting time during production. This design can significantly improve overall production efficiency. The double stackers can flexibly respond to different shearing speed requirements, ensuring that there will be no speed mismatch bottlenecks during the metal shearing process. Through the automated receiving system, the plates can be automatically processed according to different size and speed requirements, reducing the need for manual intervention, while improving the automation level of the production line and reducing the risk of human errors or accidents.

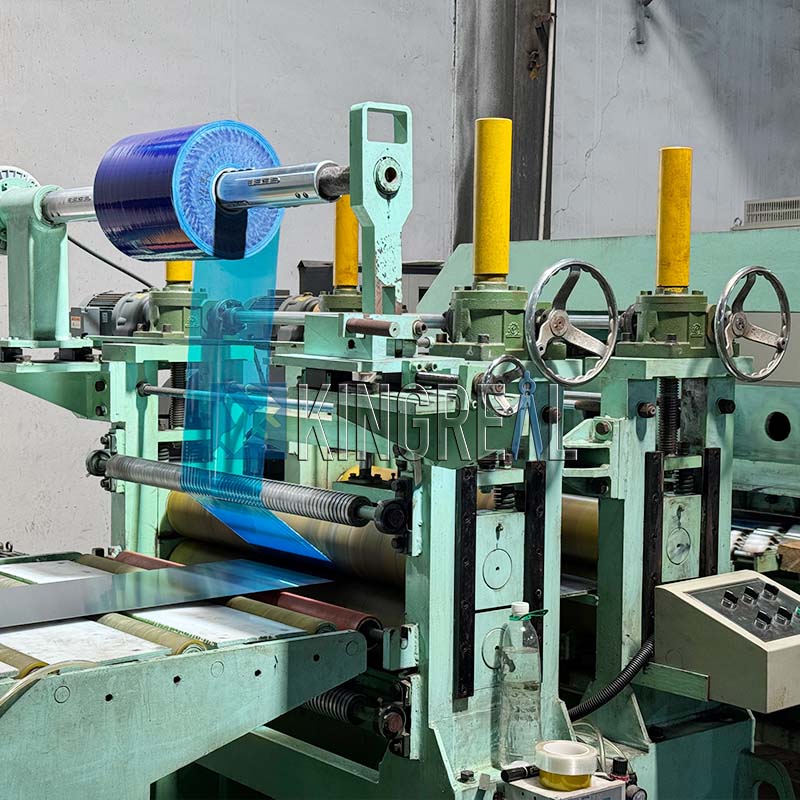

For customers who have high requirements for the surface of the plate, KINGREAL SLITTING's cut to length line machine is equipped with a laminating device. This device can automatically cover the protective film on the surface of the sheared metal plate to ensure that the surface of the plate is as bright as new, avoiding scratches, stains, etc. on the surface, especially suitable for plates with high requirements such as mirror and polished surfaces. And it is very good to prevent scratches, contamination or damage during transportation, storage or subsequent processing.