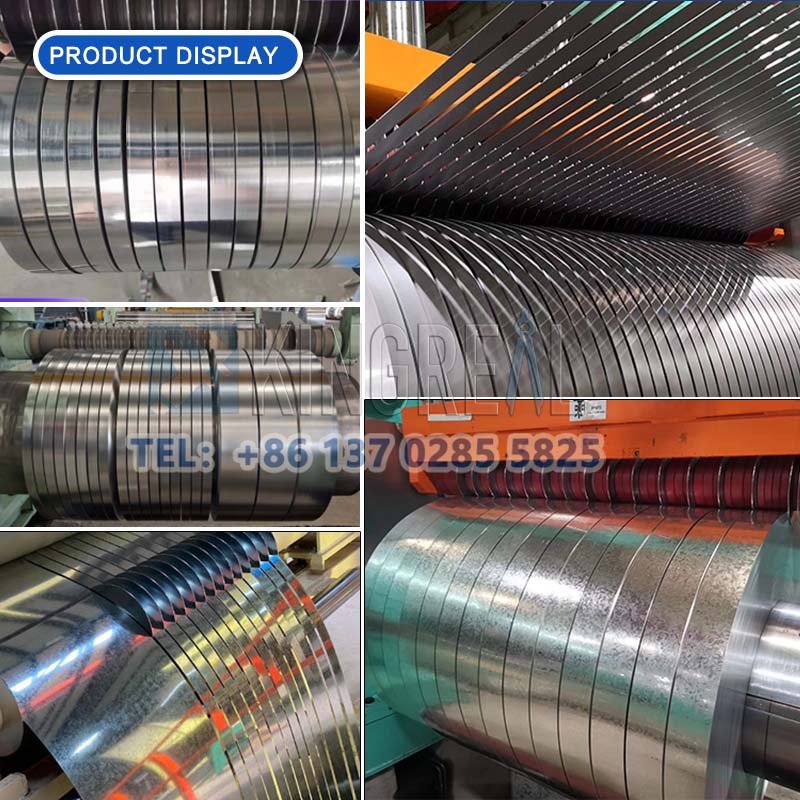

Definition of coil slitting equipment

Coil slitting equipment is a mechanical equipment specially used to cut metal sheets or metal wires into strips of specified width, which is widely used in metal processing industry. It can efficiently complete the slitting task of metal materials and provide suitable raw material size for subsequent processing links.

Main components of coil slitting equipment

The working principle of the coil slitter mainly consists of three parts: feeding system, cutting system and discharging system:

1. Feeding system: feed metal materials into the coil slitting equipment at a stable and controllable speed to ensure the smooth operation of materials during cutting.

2. Cutting system: the core part, using high-precision tools to cut metal materials into strips according to the set width.

3. Discharging system: discharge the cut metal strip materials in an orderly manner, and collect excess edge materials for subsequent processing.

The coil slitter is easy to operate and has a clear working principle. It is suitable for a variety of metal materials, such as stainless steel, aluminum plates, copper plates, etc. Due to its high efficiency and precision performance, it has been widely used in metal processing, automobile manufacturing, home appliance production and construction.

Methods to improve slitting efficiency

With the increasing market demand for slitting and the large-scale application of coil slitting equipment in factory production, how to effectively improve slitting efficiency has become a core issue of concern to many companies. The following are several effective methods to improve slitting efficiency summarized by KINGREAL SLITTING:

1. Implementing automated production lines

By introducing automated control systems and intelligent equipment, automated production lines for coil slitters can be realized. This method can significantly improve production efficiency, mainly reflected in the following aspects:

- Reduce manual intervention: The automated system can complete the entire process of feeding, cutting, and discharging, greatly reducing dependence on manual operations.

- Improve production accuracy: Intelligent equipment can accurately control parameters such as slitting width and speed, reducing errors and material waste.

- Shorten production cycle: Automated coil slitters can achieve continuous operation, greatly improving production speed.

2. Optimize production processes

In production, reasonable process design is an important means to improve efficiency. Specific measures include:

- Analyze process bottlenecks: Find inefficient links or repeated operations in production, and solve them through technical improvements or process reorganization.

- Use parallel production: For processes that can be carried out simultaneously, arrange parallel operations to reduce the waiting time of a single process.

- Batch production: Arrange production batches reasonably according to order requirements to avoid frequent equipment adjustments and raw material changes.

3. Improve operator skills

Operators are an important guarantee for the efficient operation of the coil slitting equipment, and their skill level directly affects production efficiency. Measures to improve operator skills include:

- Equipment operation training: Ensure that operators are proficient in the use of the coil slitter and can quickly complete equipment debugging and parameter settings.

- Fault handling ability: Cultivate the fault diagnosis and handling capabilities of operators to reduce downtime caused by equipment failures.

- Safety awareness improvement: Conduct safety training regularly to ensure that operators comply with production procedures and safety operating specifications.

4. Strengthen production planning and material management

Scientific and reasonable production planning and material management can effectively avoid resource waste and production delays:

- Make reasonable plans: Arrange production tasks according to market demand and equipment capacity to avoid resource waste caused by overproduction or supply shortage.

- Optimize material management: Classify and store raw materials, semi-finished products and finished products to ensure efficient use and rapid deployment of materials.

5. Regular maintenance and care

The stability of equipment is the basis of efficient production. Regular maintenance and care of the coil slitter can effectively extend the life of the equipment and reduce the failure rate:

- Mechanical component inspection: Regularly check key components such as tools, bearings, and transmission systems, and replace worn parts in time.

- Lubrication system maintenance: Regularly replace lubricating oil to ensure smooth operation of the equipment and reduce friction loss.

- Electrical system detection: Conduct a comprehensive inspection of the control system, motor, etc. to prevent electrical failures from causing downtime.

6. Optimize tool selection and maintenance

The tool is the core component of the coil slitting equipment, and its performance directly determines the cutting efficiency and quality. The following measures can help improve the use of the tool:

- Choose the right tool material: Select the tool according to the characteristics of the processing material. For example, high-hardness materials are suitable for carbide, while ordinary materials can use steel tools.

- Regularly maintain the tool: Check the sharpness and wear of the tool, replace or sharpen the tool in time to ensure that it is always in the best condition.

- Optimize tool design: adjust the size and shape of the tool according to actual needs to improve cutting speed and accuracy.