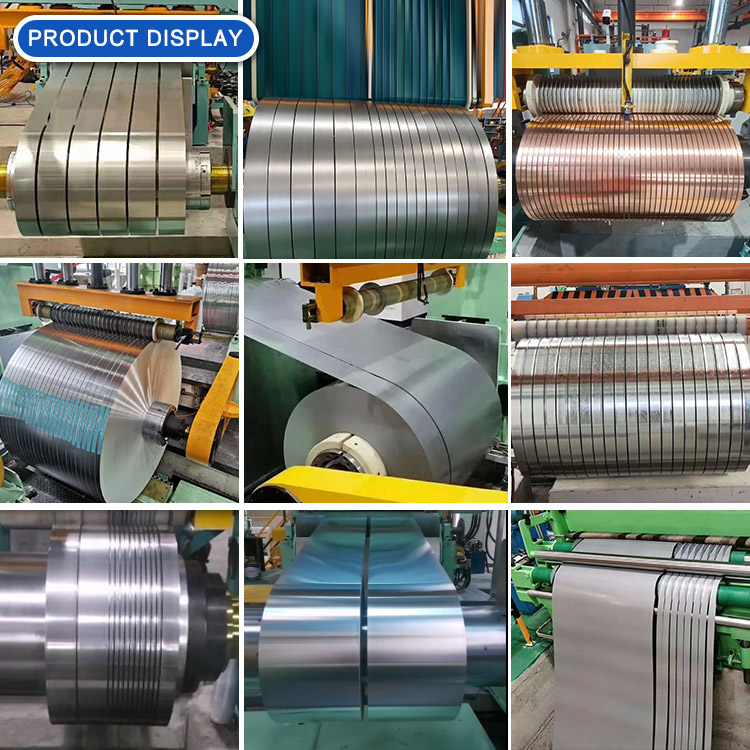

Introduction of Slitting Machine

Metal slitting machine, also known as coil slitter, is a highly efficient equipment widely used in metal processing industry. Its main function is to cut the specified width of wide metal coils longitudinally and bundle multiple narrow coils to meet different production needs.

Metal slitting machine is suitable for processing metal coils of various materials, such as carbon steel, stainless steel, aluminum, copper, etc., and is widely used in automobile manufacturing, home appliance production, building materials, packaging and hardware processing.

The working efficiency and precision of the metal slitting machine have a direct impact on the quality of downstream products, so choosing a high-performance coil slitter is crucial for production enterprises. Modern coil slitters are not only characterized by high speed and high efficiency, but also have automation technology to minimize operability, improve efficiency and reduce labor costs.

Main components of coil slitter

Metal slitting machine consists of multiple key components, each of which plays a role in the entire production line. The following are the main components of the coil slitter and their functions:

1. Decoiler

The decoiler is the starting part of the metal slitting machine, which is used to unwind the metal coils and pipe them to the subsequent process at a stable speed. The decoiler is usually equipped with a hydraulic conveying device, which can start the gap coil and has an automatic tension control function, the main shaft material or axial.

2. Leveler

The leveler is used to level the metal coil, eliminate the internal stress of the material, and ensure a smooth surface. The leveling process can effectively improve the quality of the product after slitting and provide a good foundation for subsequent processing.

3. Slitting Knife Shaft

The slitting knife shaft is the core component of the coil slitter, equipped with multiple sets of blades, which are used to cut the metal coil according to the set width. The quality and accuracy of the blade directly affect the surface finish and dimensional consistency of the slitting product.

4. Edge Trimmer

The edge trimmer is used to cut the supplementary boundary of the coil to ensure that the width of the finished product after slitting meets the requirements and improve the material utilization rate.

5. Recoiler

The recoiler is used to rewind the narrow coil after slitting into a coil, and transport and store it at the same time. Modern rewinders are usually equipped with automatic retraction and tension control functions to ensure the beauty of the rewound coils.

6. Control System

The metal slitting machine is equipped with an advanced PLC control system, which can realize automatic operation, including speed adjustment, tension control and cutting accuracy adjustment. The customized design of the control system not only improves production efficiency, but also reduces the difficulty of operation.

How to use coil slitter?

The correct use of the metal slitting machine can not only improve production efficiency, but also extend the sleep time of the equipment, avoid unnecessary loss and safety awareness. The following are the key steps and matters to be noted when using the coil slitter:

1. Preparation before operation

- Check the equipment status: Before starting the metal slitting machine, the operator needs to check whether the various components of the equipment are in good condition, including the decoiler, slitting knife shaft group and coiler. Make sure that the blade is sharp, fixed, and not loose or damaged.

- Check parameter settings: Set the slitting width, speed and tension parameters according to production requirements. Make sure that the parameters in the control system are consistent with the actual production requirements.

- Safety protection: Operators need to wear appropriate protective equipment and check whether the safety protection devices of the slitting machine are working properly, such as the emergency stop button and protective mask.

2. Precautions during operation

- Uniform feeding: During the slitting process, ensure that the coil enters the equipment evenly to avoid material deviation or rare earth phenomenon.

- Monitor the status of the blade: Observe the operation of the slitting knife shaft group in real time to ensure that the blade cuts continuously. If the blade is found to be damaged or the cut is not good, the blade should be replaced immediately.

- Tension control: Reasonably adjust the tension parameters to ensure that the coil is flat and free of ripples after slitting, and avoid deformation or breakage of the material due to excessive tension.

3. Maintenance after operation

- Cleaning equipment: After the metal slitting machineis used, the metal debris and dust on the equipment should be cleaned in time to keep the equipment clean and prevent metal debris from causing equipment wear.

- Check blade fatigue: Regularly check the fatigue of the slitting blade, replace or re-grind as needed to ensure slitting accuracy and efficiency.

- Lubrication and maintenance: Regularly add lubricants to the bearings, gears and other moving parts of the coil slitter to reduce fatigue and extend equipment wear.

- Record equipment operation: Establish equipment use and maintenance records to promptly identify and solve potential problems and ensure that the equipment is always in the best working condition.