Metal cut to length lines are an indispensable and important equipment in modern manufacturing. They are mainly used to shear metal coils of various materials (such as aluminum, stainless steel, silicon steel, cold rolling, hot rolling, etc.) into the length required by customers for subsequent processing and use. With the continuous advancement of technology, metal cut to length machines have shown obvious advantages in production efficiency, precision and flexibility. In this article, KINGREAL SLITTING will discuss the advantages of metal ctl lines in detail and analyze their importance in various industries.

1. Full automation

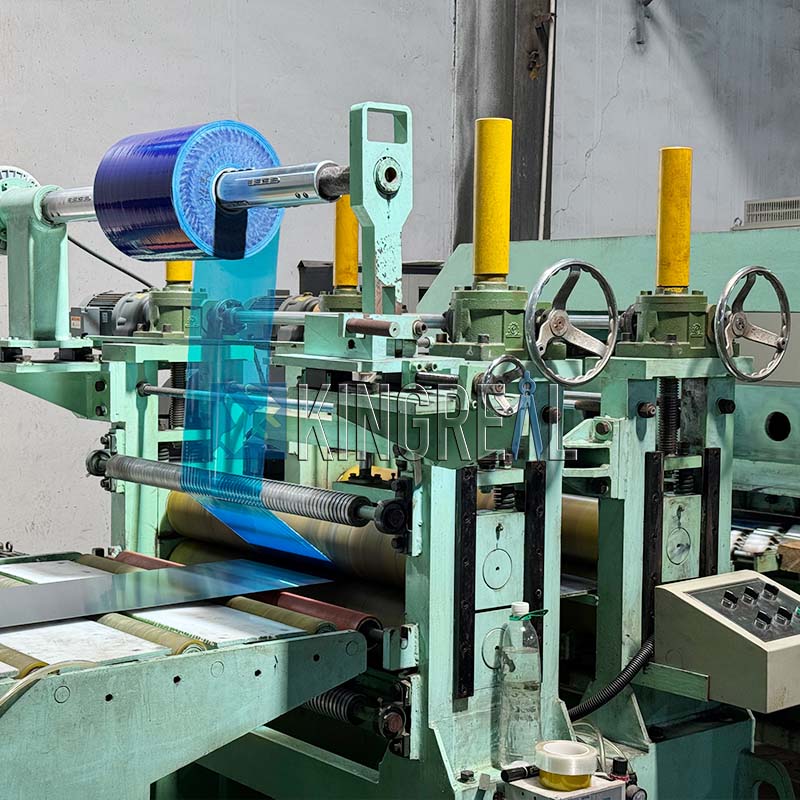

With the advent of the era of Industry 4.0, automated production has become one of the key factors in improving the competitiveness of the manufacturing industry. The fully automated design of the metal cut to length machine has significantly improved production efficiency. Traditional manual shearing is not only inefficient, but also prone to human errors. The fully automated metal ctl line uses advanced control systems and mechanical equipment to achieve a fully automated process from raw material feeding to finished product discharging.

1.1 Research and development of automated equipment

In order to meet the market demand for automation, many manufacturers (such as KINGREAL SLITTING) continue to develop new metal ctl line. For example, a metal cut to length machine with a double stacking table can achieve efficient material management during the shearing process, avoiding the tediousness of manual handling. In addition, the automated metal ctl line is equipped with an intelligent control system that can monitor the production status in real time to ensure that every link in the production process is efficient and accurate.

1.2 Improve production capacity

The introduction of fully automated metal cut to length machines allows companies to complete a large number of orders in a short period of time, greatly improving production capacity. For those customers who need fast delivery, fully automated metal ctl lines provide strong support. By reducing manual intervention, companies can not only reduce labor costs, but also respond quickly to market demand during peak production periods.

1.3 Reduce labor costs

Automated production reduces dependence on labor, and companies can allocate human resources to more creative and technical work, further improving overall production efficiency. In addition, reducing labor costs also enables companies to maintain price advantages in the face of fierce market competition.

2. Customization according to actual production needs

The flexibility of metal cut to length lines enables them to be customized according to the actual production needs of customers. Different industries have different requirements for metal sheets, including thickness, width, material properties and surface treatment. By customizing to specific needs, metal cut to length machines can better meet customers' personalized requirements.

2.1 Achieving high flatness

For example, a customer had extremely high requirements for the flatness of metal sheets, so KINGREAL SLITTING designed a metal ctl line with a double leveler. This design allows the metal sheets to be leveled twice before shearing, ensuring the flatness of the final product. This customized solution not only improves product quality, but also enhances customer satisfaction.

2.2 Adapting to diverse needs

Customized metal ctl lines can flexibly cope with metal sheets of different materials and specifications, making them suitable for a wide range of industries. For example, in the fields of automotive manufacturing, building materials, and electronic products, companies can adjust the parameters and configuration of the metal ctl line according to their specific production needs. In this way, companies can quickly adapt to market changes and remain competitive.

2.3 Continuous improvement and innovation

Customized metal ctl lines not only meet the needs of the current market, but also provide possibilities for future production development. With the continuous emergence of new materials and new processes, the design and configuration of the metal ctl line can also be adjusted accordingly to maintain the advanced technology and market competitiveness.

3. Precision Cutting

One of the great advantages of metal cut to length machines is their ability to cut precisely. High-precision shearing not only ensures that the product meets the customer's specifications, but also reduces the need for subsequent processing, thereby improving production efficiency.

3.1 Use of high-precision equipment

The metal ctl line is equipped with high-precision control equipment that can achieve millimeter-level cutting accuracy. The metal ctl line can automatically perform precise cutting as long as the customer sets the length to be cut. This high-precision cutting process not only ensures the accuracy of the length, but also effectively reduces the material waste caused by improper cutting.

3.2 Guarantee of surface quality

In addition to cutting accuracy, the precise control of the metal cut to length machine also ensures that the surface of the cut metal sheet is smooth and burr-free. This feature is crucial in many industries, especially in fields such as electronics, medical and aerospace, which have extremely high requirements for surface quality. High-quality surface treatment not only improves the aesthetics of the product, but also reduces the difficulty of subsequent processing.

3.3 Reliable production process

The realization of precision cutting enables enterprises to better control product quality during the production process. When receiving finished products, customers can rest assured that each product meets their requirements, avoiding returns and rework due to quality issues, and further improving customer satisfaction.

4. Applicable to All Walks of Life

The wide applicability of metal ctl lines is another major advantage. Almost all industries that use metal sheets can benefit from the efficiency, precision and flexibility of shearing lines. This makes metal ctl lines a basic equipment for many industries, supporting production needs in various fields.

4.1 Construction industry

In the construction industry, metal ctl lines are widely used to make various metal components and decorative materials. Builders can quickly obtain metal sheets of the required size according to the design drawings, which is convenient for subsequent installation and construction.

4.2 Automobile manufacturing

The automobile manufacturing industry has a huge demand for metal sheets. Metal cut to length machines can provide efficient and accurate metal materials to support the rapid development of the automobile industry. Through metal ctl lines, automobile manufacturers can quickly produce various shells, structural parts, etc. to ensure the smooth operation of the production line.

4.3 Electrical and electronic industry

In the electrical and electronic industry, metal sheets are often used to make equipment shells and internal structural parts. The high precision and smooth surface treatment of the metal ctl line make it an ideal choice for electronic product manufacturing, which can effectively improve the performance and appearance of the product.

4.4 Other industries

In addition to the above industries, metal cut to length machines are also widely used in aerospace, home appliances, machinery manufacturing and other fields. In these industries, the flexibility and adaptability of metal ctl lines enable them to meet different production needs and help the rapid development of enterprises.

5. Convenience of Maintenance and Service

The design of metal ctl lines usually takes into account the convenience of maintenance and service, which enables enterprises to maintain efficient production during equipment operation.

5.1 Simplified maintenance process

Modern metal ctl line is often equipped with an intelligent monitoring system that can monitor the operating status of the equipment in real time and detect potential faults in time. This mechanism reduces the risk of equipment downtime and improves production efficiency.

5.2 Timely technical support

Many equipment manufacturers provide comprehensive after-sales service and technical support to ensure that customers can get timely help when using shearing lines. This support not only includes daily maintenance of equipment, but also covers operation training and technical upgrades, helping enterprises to always stay at the forefront of technology.

5.3 Improve the service life of equipment

Good maintenance and timely technical support can significantly extend the service life of metal cut to length machine and reduce the long-term operating costs of enterprises. Through regular inspection and maintenance, enterprises can ensure that the metal cut to length machine is always in the best working condition to meet production needs.