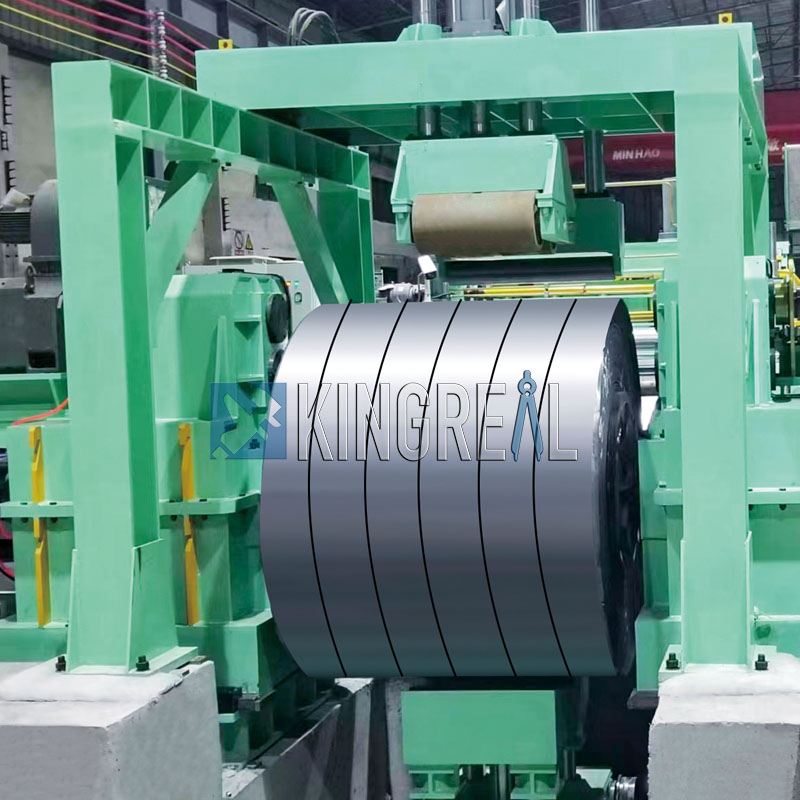

In modern industrial production, heavy duty slitting machine is an important metal processing equipment and is widely used in various industries. Its main function is to cut large rolls of metal sheets into strips of the required width for subsequent processing and use. In this article, KINGREAL SLITTING will discuss in detail the working principle, purpose and technical characteristics of the heavy gauge slitting machine to help everyone fully understand the importance and application value of this equipment.

1. Working principle of heavy duty slitting line

The working principle of the heavy gauge slitting machine is relatively simple, but it involves several key process steps. First, the equipment places the large roll of metal sheet on the feeding device, and the feeding device feeds the coil into the cutting area. The cutting process is mainly completed by the knife and the cutting mechanism.

1.1 Feeding mechanism

The design of the feeding mechanism is crucial to ensure that the coil can be smoothly and accurately fed into the cutting area. Most thick plate slitting machines are equipped with an automatic feeding system that can automatically adjust the feeding according to the set speed and length to ensure the accuracy and consistency of the cutting.

1.2 Cutting mechanism

The cutting mechanism usually consists of multiple sets of knives, which can be flat blade knives, round knives or other types of cutting tools. The material and design of the knives directly affect the efficiency and accuracy of cutting. The heavy duty slitting line can handle coils with a thickness of 6-16mm, and the knives need to have sufficient hardness and wear resistance to cope with high-intensity cutting tasks.

3. Control system

Modern heavy duty slitting machines are equipped with advanced control systems, usually using PLC (programmable logic controller) or other automated control technologies. The operator can input cutting parameters such as coil thickness, cutting width and speed through the touch screen, and the system will automatically adjust the cutting process according to these parameters. This intelligent design improves the convenience and safety of operation.

Through the above steps, the heavy gauge slitting machine can efficiently and stably complete the slitting of large coils of metal sheets, ensuring that each slitting product meets customer needs.

2. Purpose of the heavy duty slitting line

2.1 Slitting

The main purpose of the heavy gauge slitting machine is to cut large coils of metal sheets into smaller strips. These strips can be further processed according to customer needs, or directly used as raw materials for the production of other products. For example, in the automotive manufacturing, construction engineering and electrical industry, heavy duty slitting machines can cut steel plates into sizes suitable for car bodies, building structures and electrical housings.

2.2 Providing raw materials for downstream processing

Heavy duty slitting lines are not only a cutting device, but also important in providing raw materials for downstream processing. By slitting large coils, companies can more efficiently supply raw materials to various production links, reducing inventory and transportation costs. For example, in the steel industry, small coils after slitting can be directly sent to processing links such as welding and stamping, improving the operating efficiency of the entire production line.

2.3 Improve production efficiency

Another important benefit of using heavy gauge slitting machines is that they can improve production efficiency. Traditional manual cutting methods are not only inefficient, but also prone to errors, affecting product quality. Automated heavy duty slitting lines can complete cutting tasks at higher speeds and precision, reducing production time and increasing output.

3. Technical features of the heavy duty slitting machine

3.1 Cutting accuracy

The cutting accuracy of the heavy gauge slitting machine is one of its technical features. Due to the advantages of its design and manufacturing process, the heavy duty slitting machine can achieve high-precision cutting, ensuring that the width and thickness of each strip meet the preset standards. This high-precision cutting not only improves product quality, but also reduces material waste, and for enterprises, reduces production costs.

3.2 Production efficiency

The production efficiency of the heavy gauge slitting machine is extremely high, and it can complete large-scale cutting tasks in a short time. This high efficiency is due to its advanced automatic control system and high-performance cutting mechanism. Compared with the traditional manual cutting method, the heavy duty slitting machine can significantly improve the overall efficiency of the production line, allowing enterprises to respond to market demand more quickly.

3.3 Flexibility

Another notable feature of the heavy gauge slitting machine is its flexibility. The equipment can adapt to the cutting of coils of different thicknesses and materials to meet diversified production needs. Specifically, the heavy duty slitting line can handle coils with a thickness of 6-16mm and is suitable for various metal materials such as steel, stainless steel, aluminum alloy, etc. This flexibility enables heavy duty slitting lines to play an important role in different industries and help companies achieve diversified product production.

3.5 Maintenance and safety

Modern heavy duty slitting lines are also designed with maintenance and safety in mind. The equipment is usually equipped with safety protection devices such as emergency stop buttons, guardrails and alarm systems to ensure safety during operation. At the same time, the maintenance of the heavy duty slitting line is relatively simple, and regular cleaning and lubrication can effectively extend its service life and reduce the failure rate.