Introduction to light gauge cut to length line

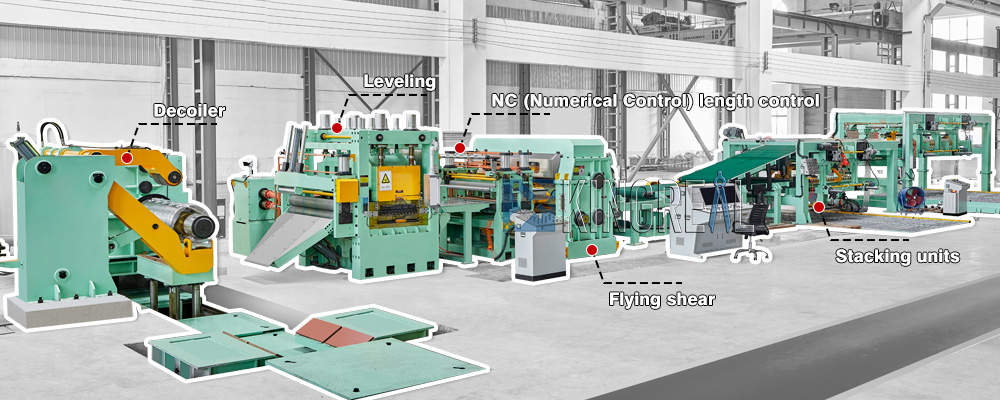

Light gauge cut to length machine is a kind of equipment specially used for cutting metal coils, which is widely used in manufacturing industry. It produces sheet metal that meets specific requirements by feeding the metal coil into the light gauge ctl line and cutting it precisely according to the set size.The light gauge cut to length machine is usually composed of a number of components, including decoiler, levelling machine, cut to length machine, feeding system and control system. It has a high degree of automation and can achieve continuous production, which significantly improves production efficiency.

The emergence of the light gauge ctl line has solved the problem of low efficiency and poor accuracy of traditional manual cutting, making the metal processing industry enter an era of efficient and accurate production. With the development of science and technology, modern light gauge cut to length machine not only has high efficiency, but also can handle a variety of metal materials to meet the needs of different industries.

Classification of light gauge ctl line

According to the thickness of the metal coil, KINGREAL SLITTING divides the light gauge ctl line into light gauge cut to length line, medium gauge cut to length line and heavy gauge cut to length line. Different types of light gauge ctl lines are suitable for different material thicknesses and application areas.

- Thickness range: 0.3-3mm

- Application field:

- Home appliance manufacturing: used to cut home appliance shell, inner liner and other components.

- Automotive industry: for the production of automotive interior, exterior trim and other light metal parts.

- Building materials: for the production of lightweight metal wall panels, ceilings and decorative materials.

The design of light gauge cut to length machine is usually focused on speed and precision, which is suitable for efficient machining of thin metal materials. The equipment can quickly complete mass production and meet the ability to respond quickly to market demand.

- Thickness range: 0.3-6mm

- Application field:

- Mechanical manufacturing: used to make parts such as shells, bases and supports for mechanical equipment.

- Marine industry: sheet metal used for shearing hull structures.

- Electrical industry: For the manufacture of enclosures and brackets for electrical equipment.

The flexibility of the medium gauge ctl line enables it to handle a variety of metal materials, suitable for the production of products requiring a certain thickness, balancing production efficiency and product quality.

- Thickness range: 6-20 mm

- Application field:

- Heavy machinery: used for the manufacture of skeletons and structural parts of large mechanical equipment.

- Steel manufacturing: For the production of large steel structures and construction steel.

- Energy industry: Metal materials used for shearing power generation equipment and heavy pipes.

Heavy gauge ctl line usually has stronger shear capacity and durability, can handle thicker metal materials, suitable for heavy industry and construction industry.

Use of light gauge cut to length machine

The use of light gauge cut to length line is very wide, not only limited to simple metal sheet cutting, but also can be used for subsequent precision component manufacturing, decorative material production and industrial equipment component manufacturing.

1. Cut sheet metal

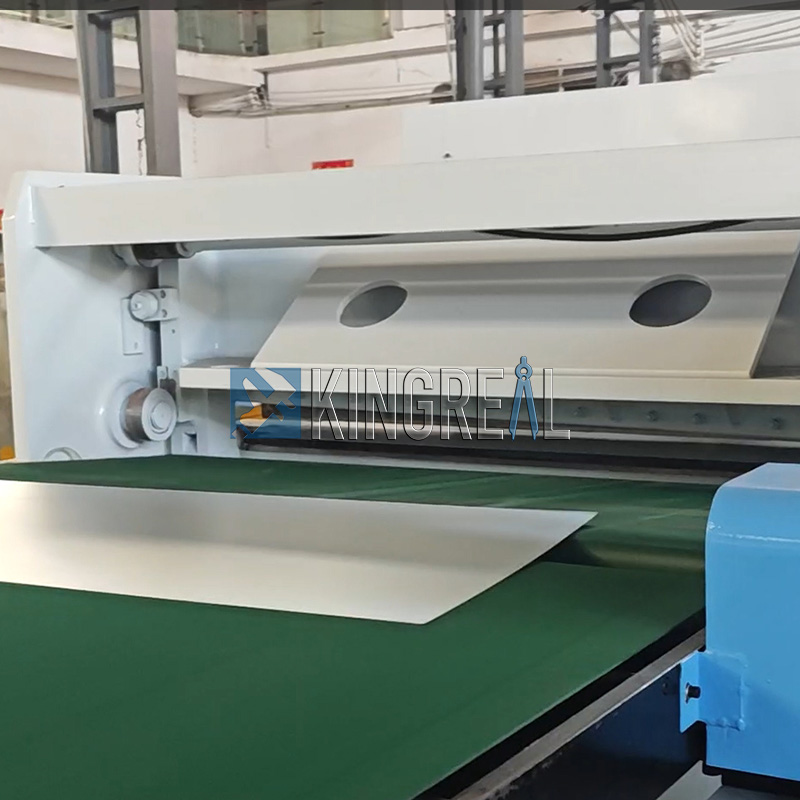

The basic function of the light gauge cut to length machine is to shear the metal coil and produce metal sheets of various sizes. These sheets can be used for subsequent processing or directly for the manufacture of finished products. In many manufacturing processes, light gauge ctl line is regarded as the basic metal processing equipment, which can efficiently meet production needs.

2. Precision parts manufacturing

In many high-precision industries, the light gauge cut to length line can be linked with other equipment to achieve the manufacture of precision parts. For example, in the electronics industry, sheets of metal cut out using clipper wire can be used to make circuit board casings or other precision components. In this case, the light gauge ctl line needs to have a high precision shear capacity and can be processed according to strict dimensional requirements.

3. Production of decorative materials

Light gauge cut to length machine is also widely used in the production of decorative materials, such as metal ceilings, wall panels and furniture components. Through the shearing and subsequent processing of the metal coil, the light gauge ctl line can produce beautiful and practical decorative materials to meet the needs of the building and home industry.

4. Manufacturing of industrial equipment components

In heavy industry and machinery manufacturing, light gauge cut to length machine is used to make various components of industrial equipment, such as frames, supports and housings. These components are usually required to have good strength and durability, so the precision and efficiency of the light gauge cut to length line in the shearing process is particularly important.

Advantages of light gauge ctl line

1. Improve production efficiency

The fully automated light gauge cut to length machine has an efficient production speed and can complete a large number of cutting tasks in a short time. Compared with the traditional manual cutting, the automatic light gauge ctl line not only improves the production efficiency, but also greatly reduces the labor cost and the occurrence of operation errors.

2. Improved cutting accuracy

Modern light gauge cut to length machine blades are made of high-precision, high-quality materials to ensure that the cut sheet is flat and consistent in size. Customers can set the cutting length according to their needs to ensure that the products produced meet the requirements. This high precision shearing capability is particularly important for precision manufacturing.

3. Adaptable

The light gauge ctl line can be adapted to different metal materials and thicknesses. Common metal materials include stainless steel, PPGI, aluminum, copper, hot rolled and cold rolled. Customers do not need to purchase multiple sets of light gauge cut to length machine for different production needs, just inform KINGREAL SLITTING of the production needs, and engineers will provide customized light gauge ctl line manufacturing solutions according to actual needs, so that customers can handle metal coils of different thicknesses and materials with one device and cut products of different lengths.