Brief introduction to cut to length line

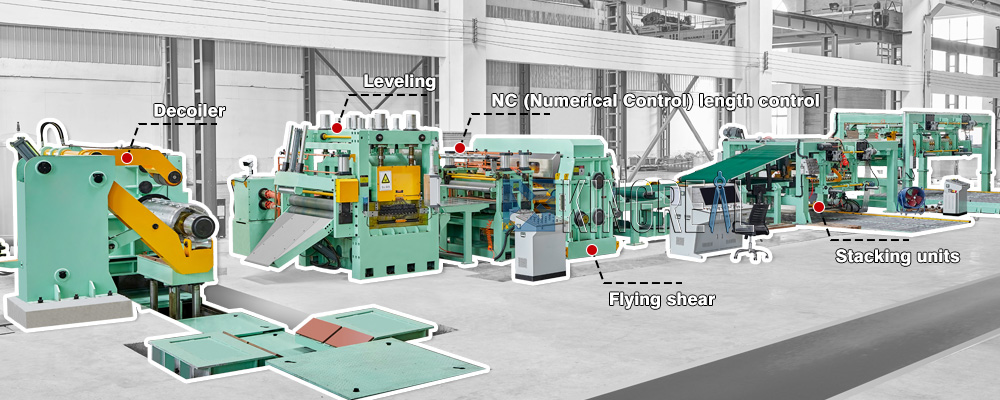

Cut to length line is to cut metal coils into the length required by customers, which mainly needs to go through uncoiling, leveling, cutting and other work processes. Cut to length line will vary according to the width, thickness and weight of the feed coil.

Importance of metal cut to length machine

● Adapt to diverse market demands

● Improve production efficiency and reduce costs

● Ensure product quality

● Adapt to the processing needs of different materials

● Promote industry standardization and competitiveness

● Meet the needs of sustainable development

KINGREAL SLITTING can provide a variety of cut to length line solutions

With more than 20 years of rich industry experience and technical strength, KINGREAL SLITTING can provide a variety of metal cut to length machine solutions according to the specific production needs of customers.

1. Different shearing methods

According to the different needs of customers for shearing technology, KINGREAL SLITTING has designed and launched cut to length lines with various shearing methods to adapt to different production scenarios:

Fixed shearing metal cut to length machine

Stop shearing is the most basic shearing method. During the shearing process, the metal sheet needs to stop moving completely. After the cutting is completed, the machine starts again and conveys the cut metal sheet to the next component.

Flying shear cut to length line

Flying shear is an efficient cutting method for continuous production lines. The shearing operation is completed while the metal sheet is running continuously through the synchronous shearing device, which is particularly suitable for high-speed production lines. The metal sheet moves at a constant speed and does not stop for cutting. The shearing mechanism moves quickly at the same speed as the wire and cuts at the right time.

Rotary shear metal cut to length machine

Continuous cutting with a rotating blade can achieve uninterrupted shearing without stopping the material, thereby minimizing the indentation of the sheet when the shearing stops and starts. It is suitable for production environments that require high efficiency and stable cutting quality.

Swing shear cut to length line

Shearing is completed by a swinging knife holder, which has high flexibility and is suitable for diversified production needs.

2. metal cut to length machines designed according to coil thickness

KINGREAL SLITTING has designed light gauge cut to length lines, medium gauge cut to length lines and heavy gauge cut to length lines for metal coils of different thicknesses to meet customers' processing needs for plates of different materials and thicknesses:

heavy gauge cut to length line

Used to process metal coils with a thickness of 6-25mm, suitable for heavy industrial fields such as shipbuilding, bridge construction and heavy machinery production.

medium gauge cut to length line

Suitable for metal coils with a thickness range of 0.3-6mm, widely used in medium-sized industrial fields such as automobile manufacturing and home appliance industry.

light gauge cut to length line

Designed for metal coils with a thickness of 0.3-3mm, suitable for light industrial fields such as the processing of electronic product housings and decorative materials.

3. Small-scale production solution

In order to meet the needs of small-scale production customers, KINGREAL SLITTING has launched a compact metal cut to length machine.

- Low cost and high efficiency: The compact cut to length line realizes basic shearing functions in a more economical way, which is suitable for small and medium-sized enterprises or trial production stages.

- Modular design: The equipment structure is simple, and functional modules can be added or removed as needed to improve production flexibility.

Small footprint: The compact cut to length line fully considers the optimization of floor space in its design, and its compact structure is suitable for production workshops with limited space.

This solution is especially suitable for customers with limited budgets but certain requirements for production quality.

4. Customized metal cut to length machine

KINGREAL SLITTING always takes customer needs as the guide and provides customers with highly customized metal cut to length machine solutions. Through in-depth analysis of customer drawings and specific production requirements, KINGREAL SLITTING can flexibly adjust the equipment configuration to meet special production needs:

Double leveling machine design

In response to customers' high requirements for the flatness of metal sheets, KINGREAL SLITTING designed two leveling machines on the cut to length line to ensure that the flatness of the sheet metal reaches a higher standard through the secondary leveling process.

To meet the efficient stacking needs of large-scale production, KINGREAL SLITTING designed a cut to length line equipped with two automatic stackers, which greatly improved the stacking efficiency and shortened the production cycle.

In response to customers' special requirements for the cleanliness of the metal sheet surface, KINGREAL SLITTING engineers added a laminating device to the cut to length line. Before shearing, the surface of the metal sheet will be covered with a protective film, which effectively avoids scratches during processing and ensures the surface quality of the product is flawless.