Video About CR Slitting Machine

Description Of CR Slitting Machine

The CR slitting line (Cold Rolled Slitting Line) is a highly efficient device specifically designed for handling metal coils or strip materials, primarily used to precisely cut wide coils into narrower strips. Here is a detailed introduction and the expanded application range of the CR slitting line.

Materials Used

“The CR slitting line is suitable for various metal coils, including but not limited to”

◇Cold-rolled steel: Known for its high strength and excellent surface quality, widely used in the automotive and appliance industries.

◇Hot-rolled carbon steel: Known for its strong mechanical properties, commonly used in construction and industrial manufacturing.

◇Silicon steel: Mainly used in the electrical industry for transformer and motor cores.

◇Tinplate: Used for manufacturing food and beverage cans and other packaging materials.

◇Stainless steel: Highly resistant to corrosion, widely used in construction, kitchenware, and medical devices.

◇Coated metal coils: Including coated aluminum plates and galvanized steel sheets, used in areas requiring corrosion resistance and decorative effects.

Application Industries

“The CR slitting line has a wide range of applications across various industries, including”

◇Steel plants: Used as a primary material processing device for breaking down large coils into smaller dimensions.

◇Electrical industry: Processes silicon steel coils used in the manufacture of cores for transformers, motors, and other electrical equipment.

◇Automotive industry: Used to produce automotive parts such as doors, roofs, and chassis.

◇Container manufacturing: Cuts metal coils into specified sizes for the production and repair of containers.

◇Building materials: Produces various metal sheets needed for construction, such as roofing, wall panels, and structural components.

◇Stamping parts manufacturing: Cuts metal coils into smaller sizes used for stamping various components.

Main Equipment Components

“The CR slitting line consists of a series of efficient mechanical devices, each playing a crucial role in the overall process”

◇Decoiler: Responsible for unwinding large rolls of metal and feeding them smoothly into subsequent processes.

◇Straightener: Corrects the coil's bends and waves to ensure flatness.

◇Slitting Machine: The core equipment used for cutting the coils into narrower strips.

◇Edge Trimming Machine: Trims the edges of the cut strips to precise dimensions.

◇Tension Device: Controls the tension of the coils during the slitting process to prevent deformation and coil collapse.

◇Rewinding: Rewinds the slit strips into smaller coils for storage and transport.

◇Scrap Collection System: Automatically collects and processes the scrap generated during the slitting process.

By reasonably expanding and optimizing the CR slitting line, production efficiency and product quality can be significantly improved, meeting the high precision and quality requirements of different industries for metal sheet processing. These devices play an indispensable role in modern industrial production, providing strong support for the development of various industries.

Working Process Of CR Slitting Line

Upload material -- Decoiler Clip feed leveler/shearer -- First Loop bridge--Guide and Slitting Scrap collection--Second Loop bridge--Tension machine -- Uncoiler slitted coil--Unload Coils

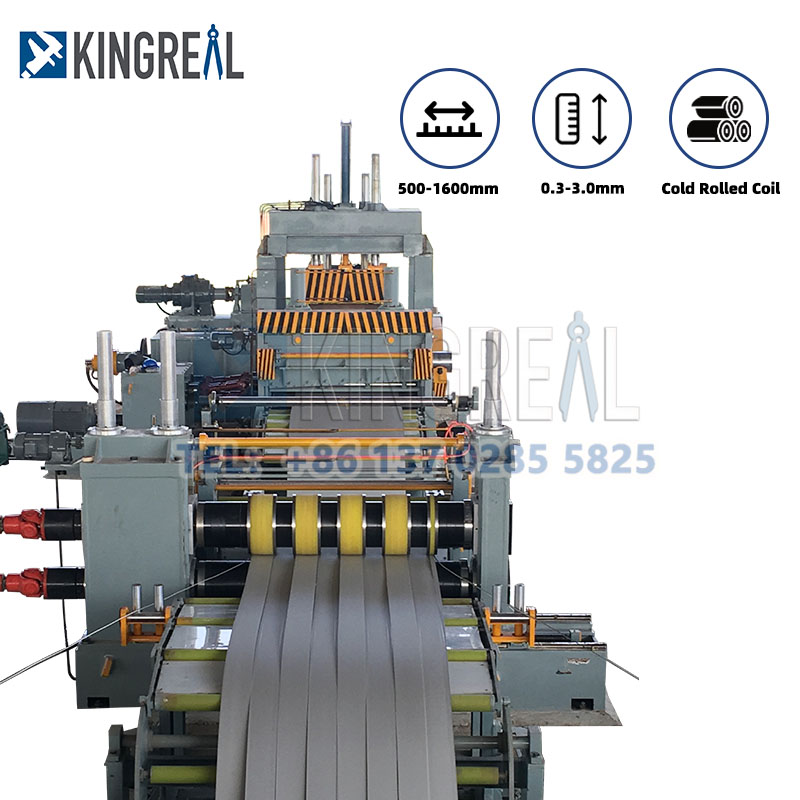

Technical Specification

No. | Name | Technical Parameters |

| 1 | Material | CR,Steel,Aluminum,Copper,Silicon |

| 2 | Thickness | 0.3-3.0mm |

| 3 | Material width | 500mm--1600mm |

| 4 | Coil outer diameter | ≤Φ1500mm |

| 5 | Coil inner diameter | Φ460-508mm |

| 6 | Max weight of coil | 25T |

| 7 | Slitting Speed | 0-120m/min(adjustable) |

| 8 | Power | 380V/50Hz/3Ph |

| 9 | Total power | ~230Kw |

Advantage Of CR Slitting Machine

1.Precision slitting effect

Cold rolling slitting machine ensures accurate and consistent cutting by adopting advanced cutting mechanism. Precise strip widths and straight edges can also be obtained with the help of adjustable cutting heads and precision leveling systems. This accuracy is critical for industries that require tight tolerances and high quality finished products, and has become one of the main advantages of roll slitting line machines.

2. High productivity

CR slitting line machines significantly increase the efficiency and productivity of metal processing. By automating the slitting process, these machines reduce manual operations and shorten processing times. They are capable of handling large quantities of material, achieving high speeds and shortening production cycles. In addition, features such as automatic coil loading, tension control systems and integrated stacking devices further streamline the entire process, maximizing efficiency and productivity.

3. Offering a wide range of optional features

CR slitting machine is designed to handle all types of cold rolled materials and metal coils of different thicknesses. Whether it's lightweight material or heavy coils, these machines offer excellent versatility to meet a wide range of processing requirements. Flexible and adjustable slitting heads, precision feeding systems and advanced tension control mechanisms ensure optimum performance and accuracy when slitting different materials. This high degree of adaptability enables the equipment to respond quickly to changes in the market, meet diversified metal processing needs, and improve production efficiency and product quality.

4. Improved material utilization

In the field of metal processing, CR slitting line is the key to ensure high-quality production. Their high-precision cutting systems ensure smooth, burr-free cuts and neat edges in strict compliance with the industry's quality standards. By optimizing material usage, these machines significantly reduce waste and increase output efficiency, thereby reducing production costs and improving overall profitability. Additionally, the automated operation and high throughput of CR slitting lines maximize product quality and consistency while increasing throughput. These features make it an important tool for modern metal processing companies to improve their competitiveness.

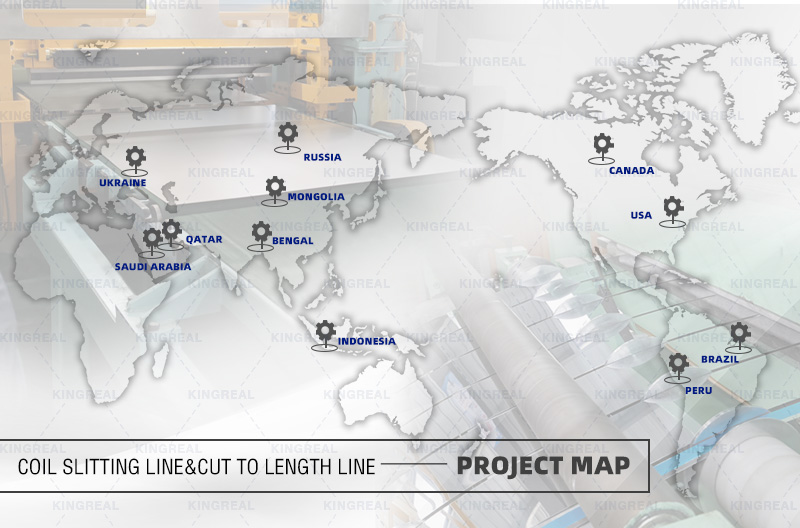

About KINGREAL SLITTING

KINGREAL SLITTING is one of the important fields of KINGREAL MACHINERY, focusing on the manufacturing of coil slitting machine and cut to length line. for more than 20 years, KINGREAL MACHINERY has been insisting on the innovation of the technology and the improvement of the service ability, and strives to provide the best service for the customers. For more than 20 years, we have been insisting on technological innovation and service capability improvement, in order to bring the best production solutions to our customers.

As of 2024, KINGREAL has successfully sold coil processing equipment to Russia, Saudi Arabia, Brazil, USA, Greece and Mexico.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil