What Is Steel Slitting Machine?

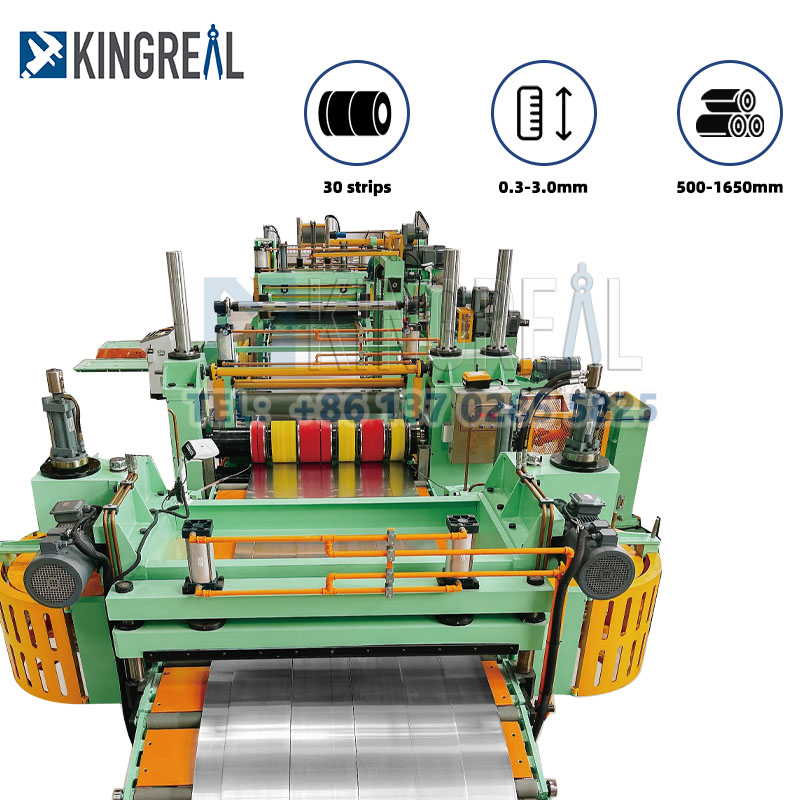

Coil Slitting Machine

Coil Slitting Machine is a machine used to cut metal coils of different materials into smaller strips. Coil Slitter is usually used in metal processing industries such as steel, aluminum, copper and other metal materials. This machine works by using a set of sharp and precise blades to quickly cut metal coils to a preset width.

The slitting width of Coil Slitting Machine can be adjusted according to the customer's needs, and the fast slitting efficiency can help customers to increase production capacity and improve market competitiveness. As a professional coil slitting machine manufacturing, we can customize design solutions according to the customer's production needs, subtle innovations and differences are likely to bring customers greater production benefits

Steel Coil Slitting Line

Steel Coil Slitting line is the most common type of Coil Slitting Machine, which produces steel coils, a metal material used in construction and industry, which can be used in building structures, machinery and equipment, transportation tools and other fields.

Steel coil slitting machine can help customers will be different thickness (0.3-3MM), different width (800-1600MM) of the steel coil for uncoiling, leveling, slitting, and ultimately rewinding out of the material to become a slitting steel coil.

Height slitting is one of the biggest features of the steel coil slitting machine, which adopts high-precision hydraulic components and DC controllers of international famous brands with high automation and excellent synchronization performance. Its shearing precision and productivity are very high, and the equipment runs stably with easy operation and maintenance. The working speed of the high-speed steel sheet slitting machine can reach 120 meters per minute.

Working Processing Of Steel Coil Slitting Line

Load raw material coil → Trolley uplift material → Manual vertical centering → Press rollers → Unbundling belt and feeding → Pinch device → Shearing Station → Looper → Guiding device → Slitting Machine with Disk Blades → Tension device → Recoiler → Trolley

Specification Of Steel Coil Slitting Machine

| NO | NAME | SPECIFICATION |

| 1 | Raw material | CR |

| 2 | Thickness | 0.3-3.0mm |

| 3 | Width | 500-1600mm |

| 4 | Coil outer diameter | ≤Φ2000mm |

| 5 | Coil inner diameter | Φ508mm、Φ610mm(With rubber sleeve) |

| 6 | Coil weight | 25T |

| 7 | Slitting Speed | 0~200m/min (Stepless speed regulation) |

| 8 | Strip through speed | 0~15m/min |

| 9 | Power | 380V/50Hz/3Phase |

| 10 | Installed Capacity | Around 400 KW |

Main Components Of Steel Slitting Machine

Full Auto Decoiler System

The main task of the decoiler is to unroll the steel coil from the reel and feed it evenly into the next process. The decoiler utilize a precise tension control system to maintain the proper tension in the coil, ensuring continuity and stability throughout the production process.

The steel coil slitting line decoiler can equipped with a loading trolley to transport heavy metal coils from storage to the uncoiler and an auxiliary support cantilever to provide additional support during uncoiling, preventing coils from sagging or deflecting under their own weight, and to help the customer carry and handle large diameter and heavy metal coils.

Pinch Device And Leveler

The steel slitting line is also equipped with a Pinch Device And Leveler, which is used to complete the coil conveying process and to help the customer in the production process of clamping and leveling the coils to prepare them for the precision of the back-end slitting process.

The Pinch Device has a high-precision clamping function that accurately clamps metal coils and prevents them from shifting during processing.The Leveler typically consists of multiple work axes through which the coil is bent and compressed several times to remove residual stresses.

Steel Sheet Slitting Machine

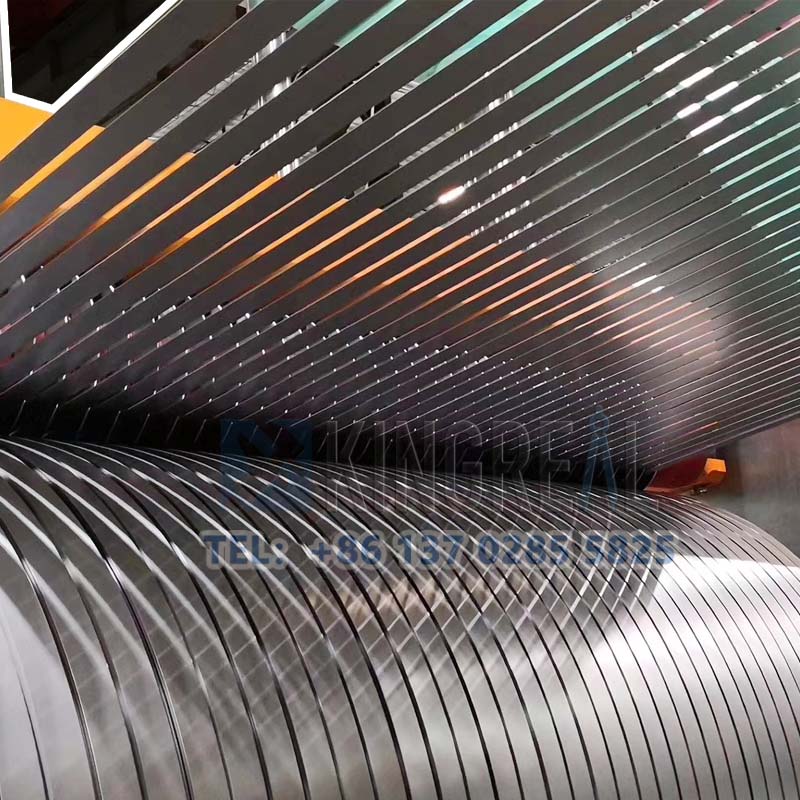

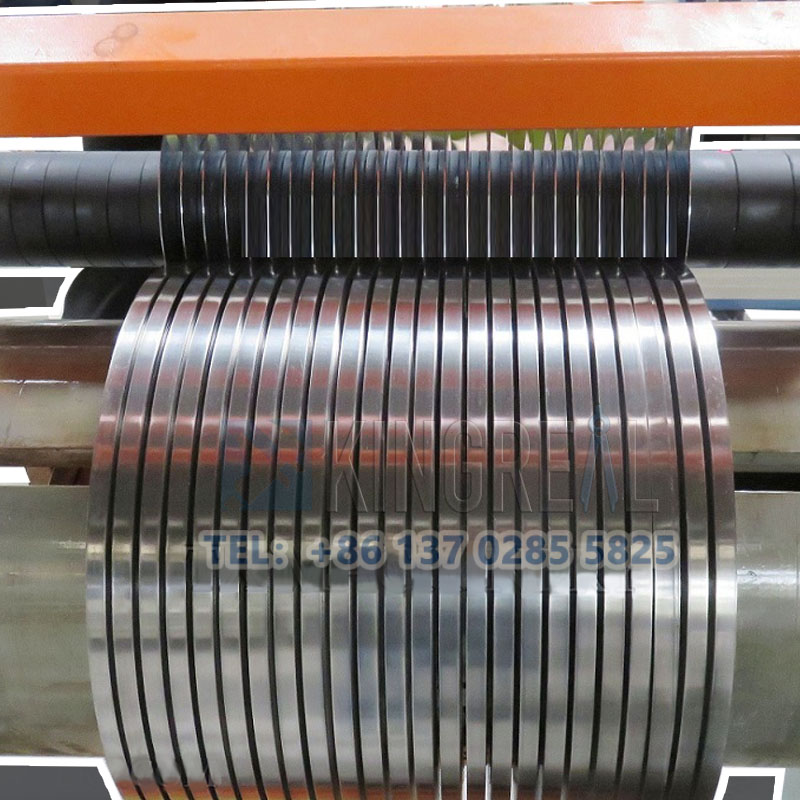

Slitter is a machine that cuts strip rolls longitudinally into various widths. The formation of the slitting is a vital part of the whole steel coil slitting line and determines the precision of the slit coil.

Steel slitting knife shaft adjustment adopts the lower shaft fixed, the upper shaft adjustment for the worm gear worm synchronization adjustment of knife shaft spacing, can accurately control the gap between the upper shaft and the lower shaft. The upper and lower knife shafts are fastened axially with nuts, and the upper and lower knife shafts are equipped with tool protection sleeves at the shaft ends.

Waste Collecting Device

A key role is played by the Waste Collecting Device (WCD), The scrap collector machine adopts the online coiling method for the collection and processing of trimmings and waste materials generated during the slitting process. By automating the scrap collection system with a conveyor, the time spent on manual scrap cleaning can be significantly reduced, increasing the overall efficiency of the production line.

Separate The Slit Strip

Separate the strips after slitting to prevent stacking when passing through the tension and to facilitate closing. There are two sets of separating disks. The shaft of the separating disk can be removed from the operating side for easy replacement and cleaning.

Recoiler

The main function of the Recoiler is to re-roll the metal strips that have been cut through the slitter into coils for subsequent storage, transportation and further processing. A certain amount of tension needs to be provided during the winding process of the steel slitting machine to ensure that the metal strips do not slip or come loose during the winding process.

Equipped with a variety of safety protection devices, such as emergency stop button, anti-overload protection and anti-coil breakage device, to ensure the safety of operators and stable operation of the equipment.

How to choose the right steel slitting solution for you?

Define your processing needs and choose a specialized supplier. Before you start looking for a steel slitting line, you need to define the processing requirements of your plant or project. The main parameters of the coil (coil weight, thickness, width, raw material, etc.) determine the different equipment of the steel slitting line. For example, if the thickness of the material is very thin, there is less need for a leveling device or the overall slitting process is relatively simple. In addition to the raw material parameters, the current production requirements also need to be assessed. The areas of application of the coils to be produced, the precision requirements, and the current production requirements also determine the production needs of the steel coil slitting line.

Choosing a professional supplier can help you get high quality products and efficient services. As one of the coil slitting line manufacturers, KINGREAL's steel slitting machine has the advantages of high customization, standardized quality assurance system, long service life of the production line and after-sales service, etc. KINGREAL will use our professional experience and level of manufacturing to create high quality steel slitting line for you and help you carry out the process. KINGREAL will use our professional manufacturing experience and level to build a high quality steel slitting line for you, and help you with after-sales installation and operation guidance, and become a long term and stable partner of our customers.

Our Professional Team

KINGREAL SLITTING professional team members have a wealth of experience in the coil processing line industry and are able to accurately understand the needs of our clients and provide solutions that meet industry standards and requirements. They are familiar with the latest technologies and processes and are able to effectively deal with various challenges during the project implementation.

KINGREAL SLITTING professional team focuses on innovation, and is able to improve product performance and production efficiency by continuously exploring and applying new technologies and processes. We are customer-oriented and always focus on customer satisfaction. Team members actively communicate with customers to understand their needs and expectations, provide customized solutions, and maintain transparent and timely communication during project implementation.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil