Video About Stainless Steel Slitting Machine

Description Of Stainless Steel Slitting Machine

Generally speaking slitting machine is suitable for mechanical equipment that cuts wide material into narrow strips or small rolls through unwinding and sharp blades, which is widely used in paper, film, foil, fabric, metal foil and other industries. Its main function is to cut and process large rolls of material and split them into multiple rolls of smaller sizes to meet the demand for subsequent production or use as raw materials for secondary processing in other industries.

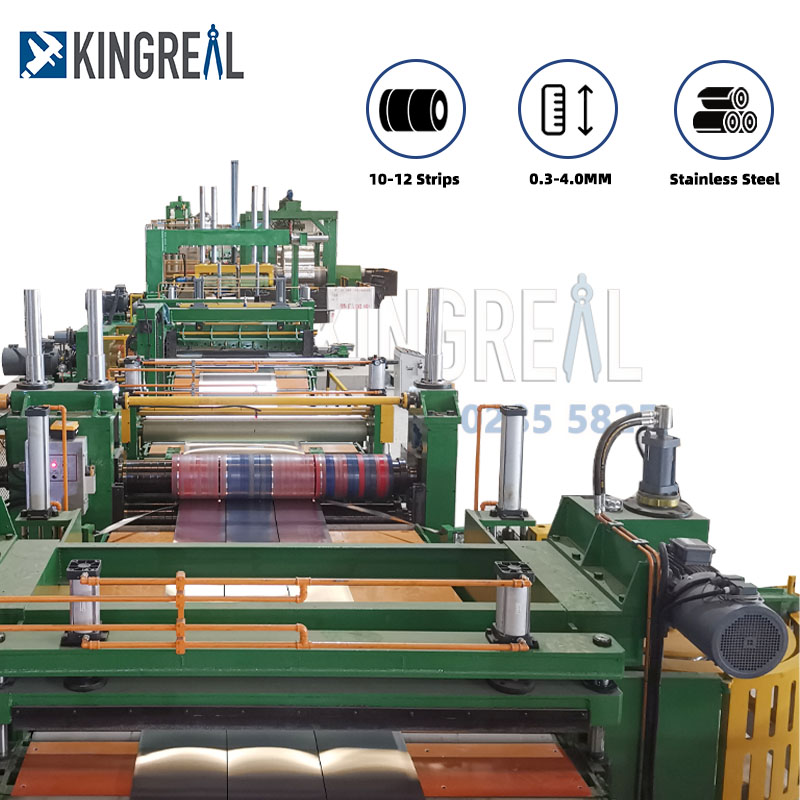

Stainless steel slitting line is specially designed and manufactured by KINGREAL SLITTING for the production of 0.3-4.0MM thick stainless steel coils which are pneumatically operated by high-precision circular slitting blades for precision slitting and final winding into small rolls. Stainless steel slitting machines have higher rigidity and precision to cope with the high strength and toughness characteristics of stainless steel materials.

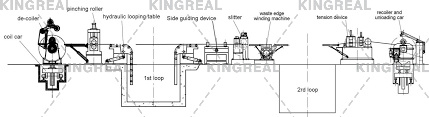

The standard components of the stainless steel slitting line include the coil transport cart, decoiler, leveler, bridge loop, metal slitter, scrap collector, secondary loop, tension mechanism, belt guiding tension mechanism, belt guiding system, rewinding, support mechanism, discharge coil cart, hydraulic mechanism, electrical control system, and so on.

All the components and equipment in the stainless steel slitting line are made of international famous electrical brands, and KINGREAL SLITTING will customize the design of the slitting line according to the customer's actual production demand and budget. At the same time, KINGREAL SLITTING has a professional technical team and high standards of Coil slitting line production, which can meet the production requirements and quality and safety standards of large steel processing plants.

Technical Specification Of Stainless Steel Slitting Machine

1) Slitter product parameters

No. | Name | Technical Parameters |

| 1 | Inner diameter | Φ508mm |

| 2 | Outer diameter | ≤Φ1800mm |

| 3 | Product Max capacity | Max:30T |

| 4 | Strip | Thickness: ≤8 strips within 1.2mm;≤3 strips above 1.5mm; |

| 5 | Min Strip width | 75-150mm |

2) Slitter product parameters

No. | Name | Technical Parameters |

| 1 | Slitting Speed | 0-100m/min(adjustable) |

| 2 | Power | 380V/50Hz/3Ph |

| 3 | Total power | ~100Kw |

Working Process Of Stainless Steel Slitting Line

Hydraulic Coil Car -- Hydraulic Decoiler -- Pinch Leveler Shear -- Front loop&Bridge -- High Speed Slitting Machine-- Rear loop Pit & Bridge -- Sheet Transmission Belt-- Recoiler

Feature Of Stainless Steel Coil Slitting Machine

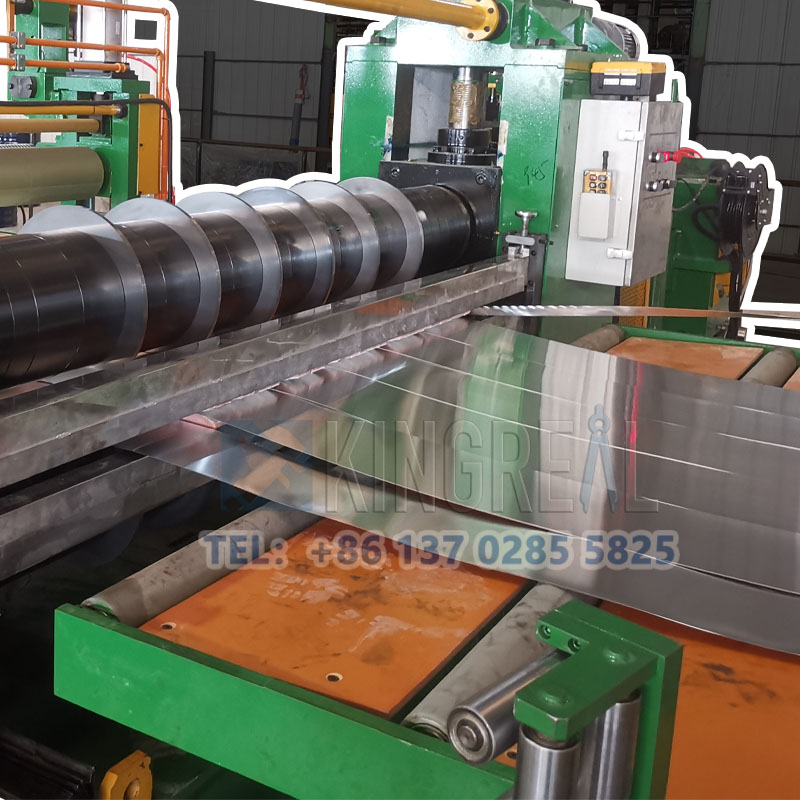

1. High-Precision Shearing System: Equipped with an ultra-precise automatic dual eccentric slitting head, it ensures automatic locking and gap setting, delivering high-quality outputs during the shearing process.

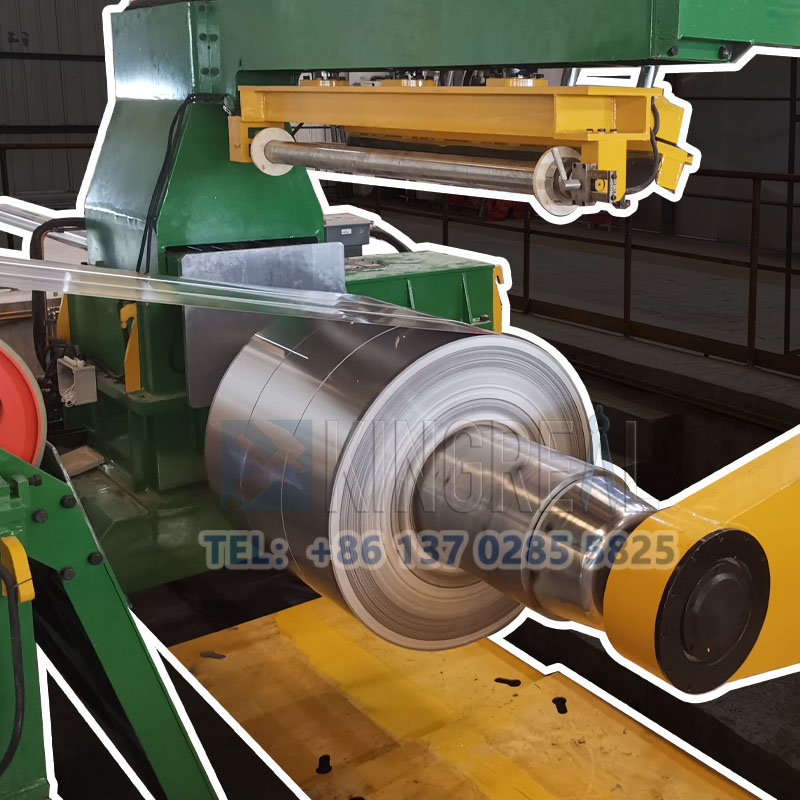

2. Advanced Tension Control: To guarantee perfect coil winding, the slitting machine uses an automatic tension control system. This system includes various types of automatic tension control solutions, such as the outward tilt compensation system, tailored to different material requirements.

3. Efficient Production Operations: Featuring an automated tool exchange system, quick threading, and offline strapping, the machine allows rapid replacement of separation shafts, maximizing production performance and minimizing downtime.

4. Stable and Reliable Performance: Designed for stability and ease of operation, the machine maintains reliable performance even under high-load production environments.

5. Easy Maintenance: With advanced control systems, operation and maintenance become more straightforward, reducing downtime and improving production efficiency.

Different Between Stainless Steel Slitting Line And Other Coil Slitting Line

Form | Stainless Steel Slitting Line | Other Coil Slitter Machine |

Slitter Blade | Stainless steel slitting machine using carbide cutting tools to meet the high hardness and high toughness of stainless steel, cutting force and easy to produce work hardening phenomenon. | Ordinary metal slitting machine tool material selection is relatively diverse, high-speed steel tools can be competent in the processing of carbon steel, while the processing of aluminum is more inclined to use soft tools, cutting less difficult. |

Automatic Control | Stainless steel slitting machines are usually equipped with advanced automated control systems that can adjust cutting parameters and tension in real time to ensure efficient and stable processing. | The requirements of the automation control system of ordinary metal slitting machine are relatively simple, mainly focusing on the control of cutting speed and precision. |

Cooling And Lubrication Systems | Stainless steel slitting machines need to be equipped with efficient cooling and lubrication systems to prevent high temperatures and tool wear generated during processing, improve machining accuracy and extend tool life. | Ordinary metal slitting machine cooling and lubrication requirements are relatively low, ordinary coolant can meet the requirements, low maintenance costs. |

Advantage Of Our Stainless Steel Slitting Line

1. Efficient automated operation: the stainless steel slitting machine's automatic tool exchange system and quick threading function enable fast switching and commissioning, significantly reducing downtime. In addition, the offline bundling technology enhances overall productivity and ensures continuous production capability.

2. Durable equipment construction: The knives and mechanical parts of the stainless steel slitting machine are made of highly wear-resistant materials with excellent anti-wear properties. This enables the equipment to maintain a long service life in high-intensity operations, reducing maintenance frequency and costs.

3. Versatility: the stainless steel slitting machine can handle stainless steel materials of different thicknesses and widths for a variety of application scenarios. Its flexibility and adaptability make it ideal for use in industrial manufacturing.

4. Stable and Reliable Performance: Stainless steel slitting machine is able to maintain stable performance and high quality output even under high loads and complex working conditions by means of high-precision mechanical structure and intelligent control system.

5. Easy maintenance and operation: The human-machine interface is friendly, the control system is intuitive and easy to operate and maintain. This reduces the technical requirements for operators and improves the overall efficiency of the production line.

Choose us as your Coil Slitting Machine supplier!

As a professional manufacturer of metal coil processing equipment, KINGREAL SLITTING has always been committed to providing customers with design solutions to meet the actual production requirements of customers, high quality assurance of coils slitting machine products and after-sales service guarantee, to become the customer's project development assistance.

Choosing the right coils slitting machine supplier is very important for customers, it is not just about buying a machine, but also about the quality of the products produced and the sustainable development of a project.KINGREAL SLITTING would like to be one of your suppliers, so that we have the opportunity to demonstrate our professionalism to you, and to give you the maximum benefit. KINGREAL SLITTING would like to be one of your suppliers.

KINGREAL SLITTING After-Sale Service

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil