Video About Light Gauge Slitting Machine

Description Of Light Gauge Slitting Machine

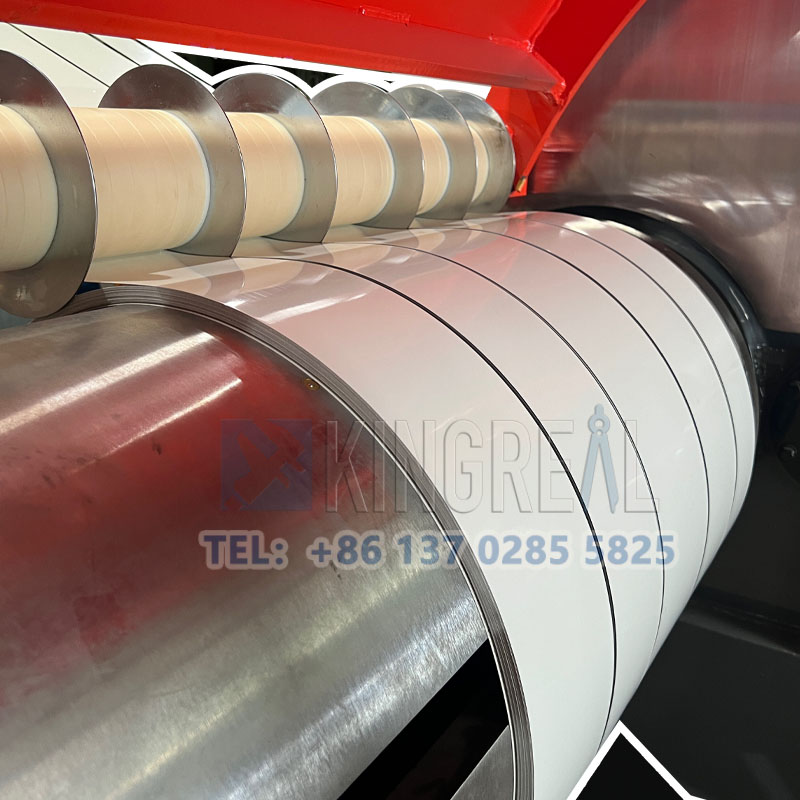

The KINGREAL SLITTING Light Gauge Slitting Machine is engineered to independently handle light-tonnage metal processing projects with remarkable efficiency. Working in conjunction with an automated system, this slitter minimizes production errors and material deformation rates, ensuring there is no production waste and that operations run smoothly and swiftly.

Versatile Slitting Solutions

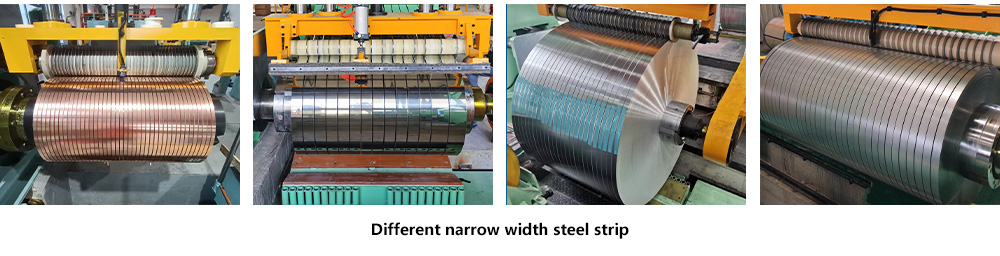

The slitting machines are categorized based on material cutting thickness into light gauge, medium gauge, and heavy gauge slitting lines. This light gauge steel slitting machine is adept at producing high-quality, smooth-surfaced products. To achieve precise slitting of metal coils, the KINGREAL SLITTING technical team has fine-tuned the slitting technology for various thicknesses.

Broad Range of Applications

The KINGREAL SLITTING Light Gauge Slitting Machine caters to the need for precision slitting of a diverse array of metal coils within the size range of 0.3-3mm thickness and 500-1650MM width. Suitable materials include:

- Steel

- Galvanized Steel

- Silicon Steel

- Tinplate

- Stainless Steel

- Aluminum

The machine is compatible with various slitting line equipment, such as:

1. Stainless Steel Coil Slitting Machine

2. Aluminum Coil Slitting Line

3. Silicon Coil Slitting Line

Flexible Production Speed Configurations

The Light Gauge Slitting Machine offers different production speed configurations to meet various slitting requirements:

1. Low Speed: 40-50M/Min for light-duty slitting tasks

2. Medium and High Speed: 80-120M/Min for moderate to high-demand projects

3. High Speed: 120-200M/Min for high-throughput operations

With its advanced technology and customizable features, the KINGREAL SLITTING Light Gauge Slitting Machine ensures precise and efficient metal coil processing, making it an essential asset for manufacturers seeking high-quality results and operational excellence.

Light Gauge Slitting Machine Component List

No. | Name | Unit |

| 1 | Coil Load Trolley Hydraulic Decoiler with Unwinding device | 1 unit |

| 2 | Material shovel, Two rollers pinch, Hydraulic Shearing Machine | 1 set |

| 3 | #1 Loop Bridge | 1 set |

| 4 | Guide Align | 1 unit |

| 5 | Main coil slitting machine | 1 unit |

| 6 | Scrap collector | 1 set |

| 7 | #2Loop bridge | 1 set |

| 8 | Hydraulic tension station | 1 set |

| 9 | Uncoiler | 1 set |

| 10 | Unloading trolley | 1 unit |

| 11 | Vertical Press Arm | 2 units |

| 12 | Hydraulic system | 1 set |

| 13 | pneumatic system | 1 set |

Light Gauge Steel Slitting Machine Technical Specification

No. | Name | Technical Parameters |

| 1 | Material | Gi,HR,CR |

| 2 | Thickness | 0.2-1.3mm |

| 3 | Material width | 500-1500mm |

| 4 | Coil outer diameter | ≤Φ1800mm |

| 5 | Coil inner diameter | Φ508mm |

| 6 | Max weight of coil | 15T |

| 7 | Slitting Speed | 0-120m/min(adjustable) |

| 8 | Threading spee | 0-15m/min |

| 9 | Power | 380V/50Hz/3Ph |

| 10 | Total power | ~230Kw |

Working Process Of Light Gauge Slitting Line

Loading Trolley -- Hydraulic Decoiler -- Roller Feeding -- Loop -- Slitting -- Waste Wire Machine -- Loop -- Separator -- Rewinding -- Unloading Car

Feature Of Light Gauge Steel Slitting Machine

1. Versatile Processing: The light gauge coil slitting machine is designed to uncoil, slit, and rewind metal coils into the required width. It is ideal for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various metal materials with surface coatings.

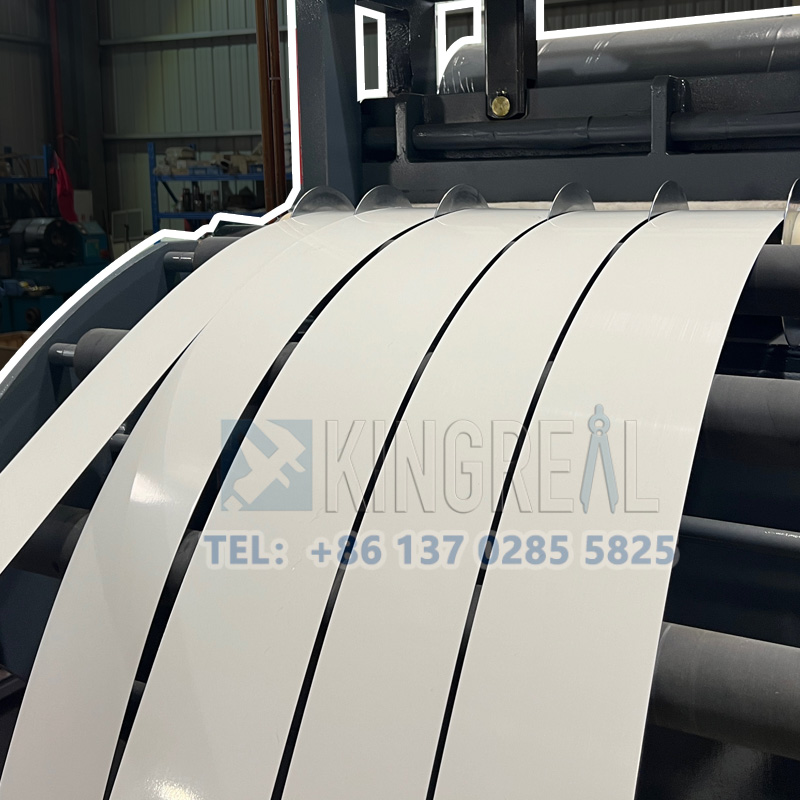

2. Enhanced Precision: For users with stringent requirements, the light gauge coil slitting line offers automatic edge or center alignment of materials. This feature facilitates feeding, improves work efficiency, enhances cutting accuracy, and protects the sheet. Additionally, you can opt for automatic edge control to ensure uniform winding, especially for wide materials.

3. Comprehensive Production Line: The light gauge coil slitting line is primarily composed of a feeding trolley, uncoiler, traction leveling machine, shearing machine, slitter, waster edge winder, tension mechanism, winder, and unloading device.

4. High Automation and Efficiency: The equipment boasts a high degree of automation, ensuring simple and reliable operation. It offers high work efficiency, fast production line speeds, and self-matching unit speeds for seamless operation.

Optional Configurations for the KINGREAL SLITTING Light Gauge Coil Slitting Line

Decoiler Machine: KINGREAL SLITTING offers a versatile range of unwinding systems, including hydraulic decoiler, auxiliary support arms, and loading trolleys. These options support large rolls and fully automate the unwinding process, enhancing efficiency and ease of use.

Dual Slitter Head: The coil slitting line can be equipped with a dual slitter head, allowing for quick adjustments to slit different-sized coils. By incorporating guide rails and other mechanisms, the dual slitter head can pre-adjust to the desired size, meeting diverse slitting requirements with precision and speed.

Belt Tension Station: During the slitting process, the belt ensures even and smooth material transfer to the cutting position. Proper belt tension is crucial for maintaining material stability, preventing slippage and deflection. Correct tension also protects materials from damage and reduces wear, extending the lifespan of both the belt and the drive system.

Automated Packaging Line for Slit Coils: An automated coil packaging line efficiently cuts, coils, and packages metal coils like aluminum and steel into standardized bundles for transportation and storage. Utilizing robotic arms, conveyor belts, and other automated components, this system ensures seamless integration with the slitting line for fully automated slitting, rewinding, unwinding, and packaging operations, ideal for large-scale steel processing plants.

Different Between Light Gauge Slitting Machine And Heavy Gauge Gauge Slitting Machine

No. | Light Gauge Slitting Machine | Heavy Gauge Slitting Machine |

Coil Thickness | 0.3-3M | 6-20MM |

Coil Thickness | Thin steel, stainless steel, aluminum and copper | Thick steel plate, stainless steel, galvanized steel, etc. |

Structural Design | Relatively small diameters of the main and secondary shafts, suitable for handling lighter loads | Larger diameters of the main and sub spindles to provide sufficient rigidity and stability to cope with high load conditions. |

Application | Ideal for small and medium-sized fabricators: for handling smaller batches and lighter metal fabrication needs | Suitable for large-scale processing plants and steel companies: for high-intensity, high-precision heavy metal processing tasks, commonly used in mass production. |

Reference Data of Slitting Coil

Thickness | Width | Roll weight | Finished width | Shearing velocity (MAX) | Shearing velocity (MAX) |

0.15-2 | 800-1600 | 30T | ≥20mm | 200m/min | 25*10 |

0.5-4 | 800-1600 | 30T | ≥40mm | 120m/min | 25*10 |

1-6 | 800-1600 | 30T | ≥60mm | 80m/min | 25*10 |

2-8 | 800-2000 | 30T | ≥70mm | 60m/min | 30*11 |

3-10 | 800-2000 | 30T | ≥80mm | 50m/min | 35*11 |

3-12 | 800-2000 | 30T | ≥100mm | 40m/min | 35*11 |

3-14 | 800-2000 | 35T | ≥100mm | 40m/min | 36*11 |

3-16 | 800-2000 | 35T | ≥120mm | 35m/min | 36*11 |

5-20 | 800-2000 | 40T | ≥120mm | 30m/min | 38*11 |

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil