3 in 1 (Uncoiler, straightener & servo feeder) is one of our most featuring products of KINGREAL MACHINERY which had been focused on the design and production of the 3 in 1 (high precision straightener servo feeder with uncoiler) for almost 3 decades.

3 in 1 (Uncoiler, straightener & servo feeder) is one of our most featuring products of KINGREAL MACHINERY which had been focused on the design and production of the 3 in 1 (high precision straightener servo feeder with uncoiler) for almost 3 decades. The 3 in1 (Uncoiler, straightener & serve feeder) is application at the Aluminum, Steel, Copper punch production area.

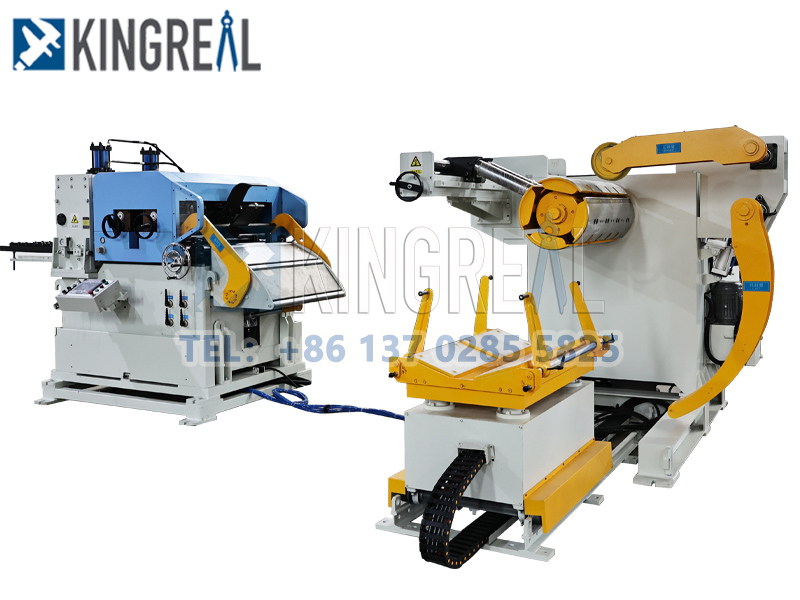

NCKR-600 3 in 1 (HIGH PRECSION SERVO FEEDER, STRAIGHTENER WITH UNCOILER)

![]() OPTION ACCESSORY:

OPTION ACCESSORY:

1. Die-high electric conditioning

2. Hydraulic Material Feed-in Cart![]() Description and Structure

Description and Structure

3 in1 (Uncoiler, straightener & serve feeder) can applicable of material width 50-1200mm and thickness range 0.3-6.0mm. And 3 in1 (Uncoiler, straightener & serve feeder) is the integrated system including material decoiler, high precision strainghtener, servo feeder. And at the for the press feeder is the top tech application of 3 in1 (Uncoiler, straightener & serve feeder) , and as following is the brief introduction of each part:

A. MATERIAL DECOILER:

the uncoiler use hydraulic expansion system and it can auto expansion and release the material which is featured with stable, low labor consumption. The material press arm adopt frequency speed adjust, single direction clutch drive and the material coil won‘t loose. The decoil of material is automatic with photoelectric system. The material input rail adopt pneumatic and it equipped with pneumatic panel press device at the material input inlet and the material head can be pressed down and send to the straightener.

B. SERVO FEEDER:

the servo feeder is high precision import brand equipped with worm reduction box, metal corrugated pipe coupling which is featured with no drive space, no rotate error. And it use encoder to control the material feeder accuracy, it will auto compensation to make it accurate and low error.

C. STRAIGHTENER:

The straightener roller adopts bearing steel high frequency quenching chrome hard plated processed and the hardness is up to 62 degree. There is not any adjustable strength structure inside the roller to ensure the roller strength. And the top roller adopt 2 points adjust structure and with worm and gear to adjust the pressure depth which is high precision and easy to operate. The release part adopt pneumatic crank arm linkage mechanism which is featured with high precision with good self-lock performance. The loose of straightener adopt Eccentric structure which is through the signal from the press.

D. MACHINE HEAD:

the output height adopts worm lift system to make the height is adjustable in certain height. And the output height adjust range is 150mm according the press line height.