The Thick Plate-Decoiler Straightener Feeder is designed with a thickness of 0.6-6mm for professional coiled steel materials.

![]() Device Description:

Device Description:

The Thick Plate-Decoiler Straightener Feeder is designed with a thickness of 0.6-6mm for professional coiled steel materials. It has the characteristics of comprehensive functions, compact structure, convenient use, high leveling and feeding accuracy, low wear-resistant parts loss, and multiple functions in one machine.

![]() Standard Configuration:

Standard Configuration:

l Touch screen man-machine interface operation

l Material rack air pressure disc brake device

l Feeder motor frequency conversion speed regulation

l Photoelectric arc control system

l Material roll head flattening device

l Material rack hydraulic expansion link type

l Feeding outlet guide frame device

l Support arm, press arm, stop arm device

l Material rack spindle support arm (material weight>10T)

l Automatic height adjustment device for feeding line

l Material arc control roller

![]() Parts Display:

Parts Display:

1. Automatic adjustment of leveling pressure:

The touch screen sets the parameters, the inverter communicates with the PLC to control the motor speed, and the PLC changes the frequency of the inverter according to the field speed measured by the encoder, so as to realize the automatic adjustment of the leveling pressure.

2. The length counting wheel completely eliminates accumulated tolerances:

Through the fully closed-loop circuit design, the length counting wheel, the rotary encoder and the servo motor cooperate to realize the real-time automatic calculation of the length of each feed, safely eliminate the trouble of accumulated tolerance, and improve the accuracy of feeding.

3. Automatically adjust the speed of the active pressing wheel:

The touch screen sets the parameters, the inverter communicates with the PLC to control the speed of the motor. The PLC changes the frequency of the inverter according to the field speed measured by the encoder, so as to realize the automatic adjustment of the speed of the pressing wheel and the change of the outer diameter of the material roll to ensure that the roll is not broken.

4. Automatic adjustment of the stop arm:

The baffle arm is powered by a hydraulic motor, instead of manual adjustment, with a higher degree of automation.

![]() Features:

Features:

1. Suitable for feeding and correcting various metal sheets.

2. It is suitable for continuous stamping processing of various hardware, electronics, electrical appliances, toys and auto parts, feeding correction, accurate and durable.

3. The equipment roller and the correction roller are plated with hard-winding treatment, high precision and very durable.

5. Equipped with a liftable upper roller seat device and a material width adjustment stopper device.

6. The height is adjusted by a screw worm gear, and the material rack contains an air pressure disc brake device.

7. It is widely used in the automobile industry, with wide material thickness adaptability, high safety and stability, and it is a substantial and light-weight model.

![]() Technical Reference:

Technical Reference:

|

Material thickness [mm] |

0.6-6.0 |

|

Inner diameter of coil [mm] |

470-530 |

|

Coil outer diameter [mm] |

1400 |

|

Maximum speed [m/min] |

18 |

|

Correction roller [mm] |

Up 4 down 3 |

|

Feeding roller [group] |

1 |

|

Standard feeding height [mm] |

1200±100 |

|

voltage |

220V AC 50HZ/380V AC 50HZ |

|

Air pressure [kgf/cm] |

5 |

|

Material rack expansion method |

Oil pressure |

![]() Who Are We?

Who Are We?

KINGREAL Machinery is a professional manufacturer and supplier. We offer full solutions in coil processing and machine tool building, which including high speed coil slitting line, copper slitting machine, 200m/min coil slitting machine, simple slitting machine, cut to length line machine, fly shearing for cut to length machine, coil ctl machine.

We have a professional team and rich project experience, can provide you with the best service, welcome to contact us.

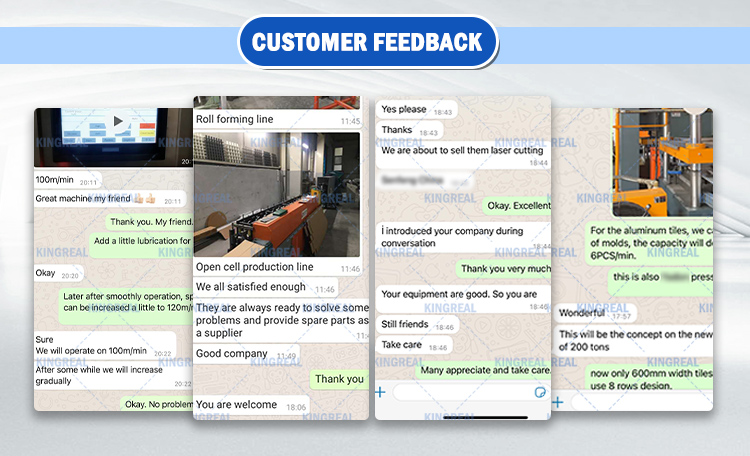

![]() Customer Feedback

Customer Feedback

KINGREAL has rich experience in production and sales, and is committed to providing customers with the best solutions to solve customer problems. At present, it has been recognized by customers from all over the world.