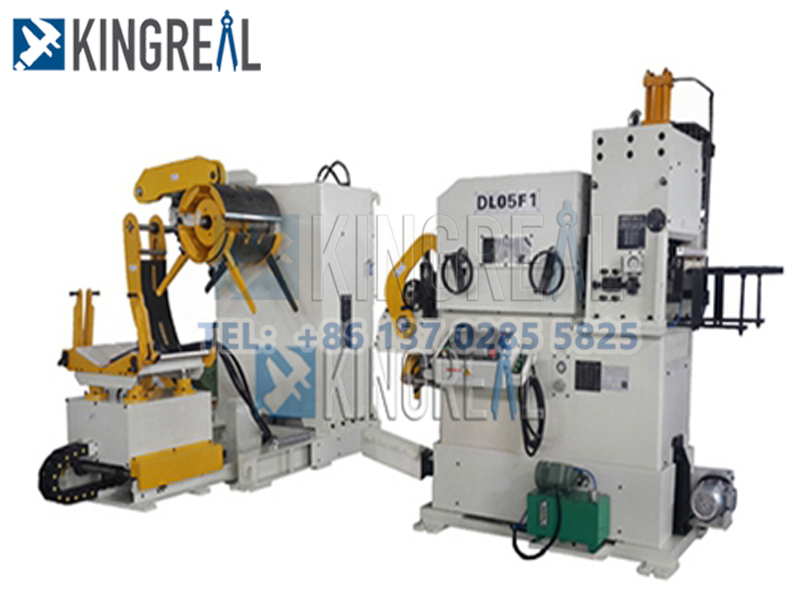

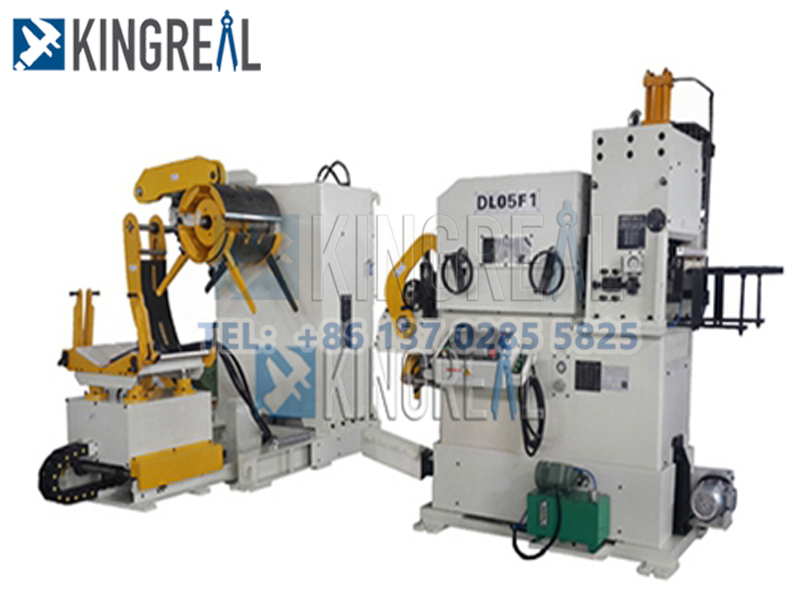

The thin-plate decoiler straightener feeder combines the functions of the roll holder, the feeding trolley, the straightening machine, and the feeder, which greatly reduces the area occupied by the previous feeding device and can work with the punch at the same time.

![]() Device Description:

Device Description:

The decoiler straightener feeder combines the functions of the roll holder, the feeding trolley, the straightening machine, and the feeder, which greatly reduces the area occupied by the previous feeding device and can work with the punch at the same time.

The material roll mounted on the material roll rack is controlled by the sensor below the material roll. The NC feeder can be used to level one side and simultaneously send the material with a preset length into the punch die simultaneously.

![]() Equipment Composition:

Equipment Composition:

1. Photoelectric arc control system

2. The feeding roller and the correction roller are plated with hard coating

3. Feeding outlet guide frame device

4. The height of the feeder line adopts a screw worm gear adjustment device

5. Material arc control roller

![]() Characteristic:

Characteristic:

1. High-precision feeding: The three-in-one feeder adopts Mitsubishi PLC with Japanese imported servo motor and supporting drivers to achieve stable and high-precision feeding, with an accuracy of up to 0.02mm.

2. Save floor space and space: The three-in-one leveling feeder has the functions of unwinding, leveling and feeding together. There is no need to equip the leveling machine and material rack. The main features are space-saving and reducing the waiting area. The feeding and leveling accuracy is higher.

3. Convenient and fast loading and unloading: equipped with a loading trolley: the material is safely and smoothly moved to the expansion and contraction structure of the decoiler‘s main shaft, which is used to hold the material during uncoiler, so that the material belt can enter the leveling machine smoothly.

4. Multiple functions: The thin plate three-in-one feeder can be customized to multi-stage feeding according to customer needs, and each group provides 999 stamping times.

5. Durability and abrasion resistance: The feeding roller and the leveling wheel are specially heat-treated, with high hardness (HRC62 degrees), wear resistance and long service life.

6. Easy to operate and easy to learn: The operation panel adopts a color LCD display, a large touch screen, a high-definition operation screen, and the operation safety protection system can be operated with peace of mind even for the first-time users.

7. Time saving and safety: The humanized design of the sound operating system shortens the preparation work, and the advanced automatic diagnosis system assists the operator in quickly mastering the operating performance of the machine.

8. Save labor and time: feeding, feeding, blocking, folding, leveling, feeding, and reloading are all completed by one machine, and one person can complete the point-controlled operation on the independent console, which is great Save labor and reduce labor intensity.

![]() Equipment Automation Description:

Equipment Automation Description:

1. The input needs data to be automatically adjusted

2. Automatic feeding hydraulic trolley

3. The hydraulic expansion and contraction method of the inner diameter of the coil frame is changed

4. The air pressure of the stop arm automatically rises

5. The pressing arm rises and falls manually and automatically

6. Automatic hydraulic feeding device

![]() Our Customers

Our Customers

![]() After-Sale Service

After-Sale Service