In order to maximize the slitting speed of the coil slitting machine, KINGREAL designed this Double Slitter Head Slitting Machine to reduce the time for changing the knife seat and improve production efficiency. The maximum production speed reaches 220m/min.

![]() Description of Double Slitter Head Metal Slitter

Description of Double Slitter Head Metal Slitter

KINGREAL is a professional coil slitting machine supplier in China, in order to meet the needs of factories with large daily output for fast slitting, Kingreal launched this double head slitting machine. KINGREAL Double Slitter Head Metal Slitter is suitable for carbon steel, stainless steel, pre-painted/coated coils, etc. Thickness up to 3mm, maximum width up to 2000mm and maximum speed up to 220 m/min.

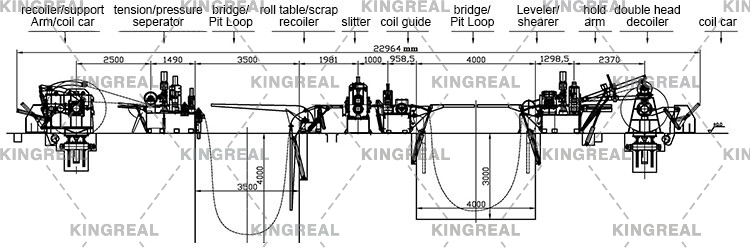

Metal slitter consists of an uncoiler with a coil car, a clamping and shearing device, a high-precision slitter for quick exchange, a waste rewinder, a side guide, a winding machine, a tensioning device, and a hydraulic winder with the coil car.

![]() KINGREAL Coil Slitting Machine Successful Projects

KINGREAL Coil Slitting Machine Successful Projects

![]() Why You Need a Slitting Machine Equipped With Dual Slitter Head

Why You Need a Slitting Machine Equipped With Dual Slitter Head

If a slitting line only has one slitting head on a line, the following operations are required if the operator replaces the slitting head:

- Hydraulic cylinder pushes operator side slitting frame out

- Install slitting knives, spacers and rubber pads on the double slitting spindle.

- Pull the slitting frame back to connect with the double spindle and press down mechanism.

The parts replacement process takes some time, obviously for a busy production factory, time is very precious. To solve this problem, KINGREAL has a double head replaceable slitting machine, we call it "double slitting head" ” or “dual slitter head”.

While one slitting head is slitting on the production line, operators can install knives and spacers on the other slitting head.

![]() Working Proesses

Working Proesses

Coil loading Trolley → Hydraulic Decoiler → Pinch Straightener → Pit Loop → Coil side guider → Guide Align / Disc slitting → Side Scrap Collector → Pit Loops → Tensioner → Rewinder Machine → Coils Unloading → Finished Products

![]() Parameters of Metal Slitter

Parameters of Metal Slitter

|

Material of raw materials |

stainless steel, cold-rolled steel. |

|

Raw material thickness |

0.2mm-2.0mm |

|

Raw material width |

300-1550mm |

|

Raw material roll inner diameter |

Φ508mm |

|

Raw material roll outer diameter |

≤Φ1800mm |

|

Raw material volume weight |

≤12 tons |

|

Slitting speed |

up to 220m/min |

|

Total power |

about 150KW |

|

Floor area |

about 18m × 6m |

![]() What Can You Get By Using Double Slitter Head Slitting Machine

What Can You Get By Using Double Slitter Head Slitting Machine

| 1. Flexible Production The double slitting heads can be the same, or one can be larger and the other smaller. Larger slitters are suitable for slitting of larger thicknesses, while smaller slitters are suitable for slitting of small thicknesses. In this way, high-precision, high-efficiency performance is achieved. 2. Saving Labor One person can change the slitter head easily, saving labor. |

|

![]() Applicable Materials of Slitting Machine

Applicable Materials of Slitting Machine

Cold rolled steel coils, hot rolled carbon steel coils, stainless steel coils, copper, brass, aluminium and silicon steel and many other materials are also suitable for processing on this line.

![]() Installation Service

Installation Service

In order to help our customers solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange for engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

![]() KINGREAL in Canton Fair

KINGREAL in Canton Fair