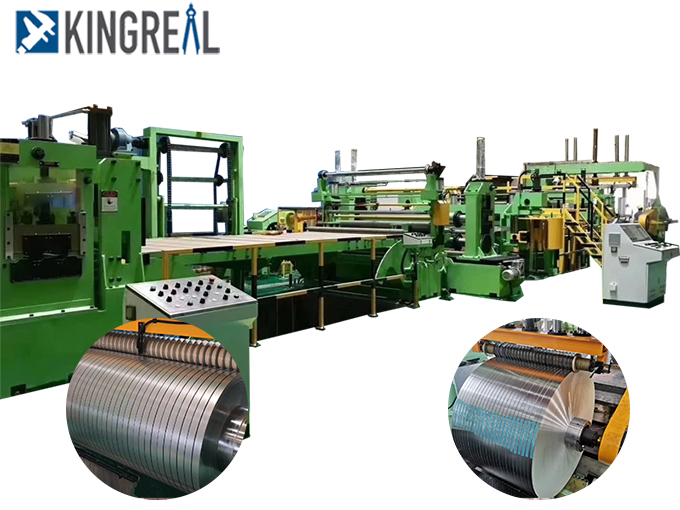

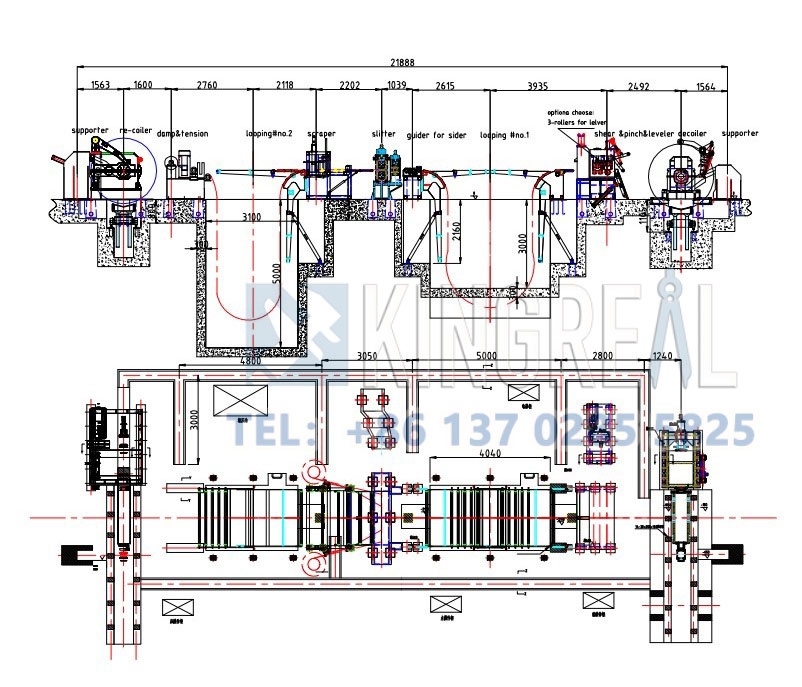

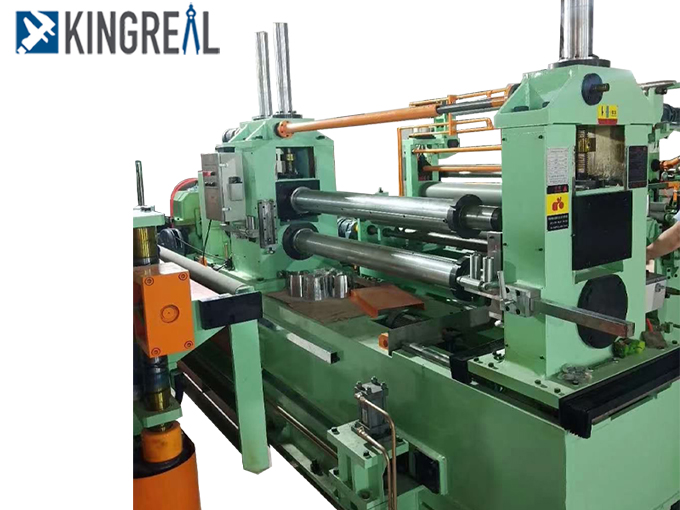

KINGREAL Slitting Line Machine is designed for slitting rolls of different materials into specific widths and rewind them automatically.

This slitting machine is capable of processing different materials such as cold rolled steel coils, hot rolled carbon steel coils, stainless steel coils, copper, brass, aluminum etc.

Click here to learn the difference between a Coil Slitting Machine and a CTL Machine and more information about the machines.

![]() KINGREAL Technical Team

KINGREAL Technical Team

KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Coil Slitting Machine, from design - production - installation - after-sales, KINGREAL has an excellent standard.

KINGREAL has established a localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India etc.. Localized service points in other countries are also in progress.