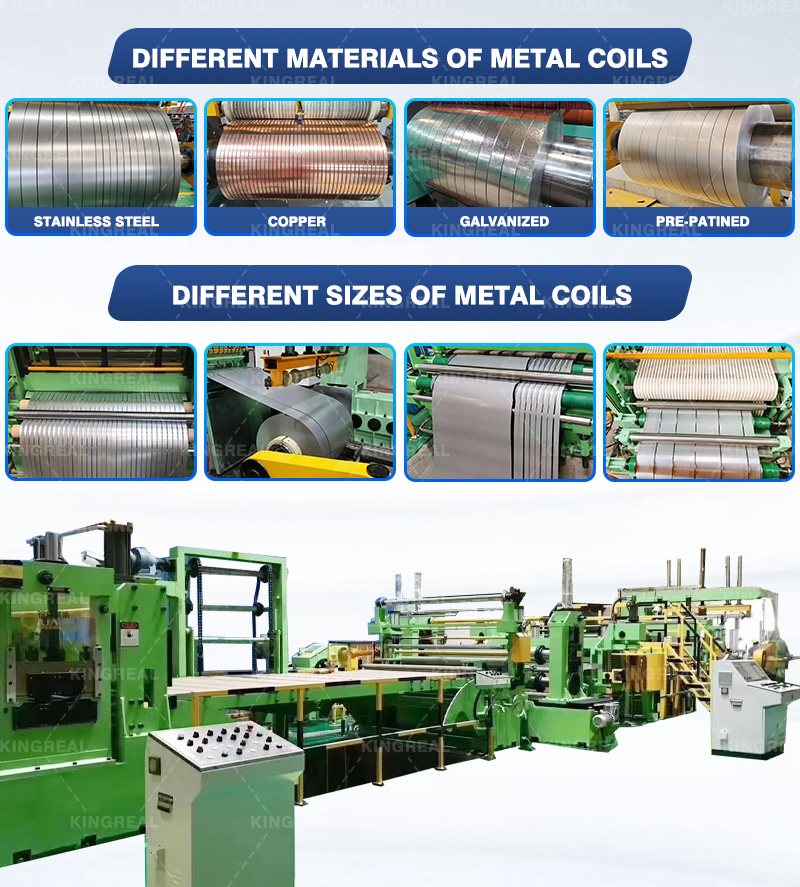

KINGREAL Full Automatic Thin Plate Coil Slitting Machine is designed for slitting rolls of different materials into specific widths and rewinding them automatically .

The metal slitter is applicable to coil raw materials including HR, CR coil, aluminum, copper coil, silicon steel, stainless steel, color steel, AI and PPIG, etc.

![]() Description of Thin Plate Coil Slitting Machine

Description of Thin Plate Coil Slitting Machine

KINGREAL automatic thin plate coil slitting machine can independently complete large-tonnage metal processing projects. The thin plate coil slitter works in conjunction with an automatic system to minimize production errors and deformation rates of the material. In this way, there is no production waste, and production runs smoothly and quickly.

According to the material cutting thickness, there are thin plate slitting machines, medium and thick plate slitting lines and medium & thick plate coil slitting machines. Products of high quality and smooth surface can be easily processed with this machine. In order to slit metal coils more accurately, Kingreal‘s technical team has adjusted the coil slitting technology of different thicknesses.

![]() Parameter of Slitting Line Machine

Parameter of Slitting Line Machine

| Raw material :thin plate, cold-rolled plate Raw material thickness : 0.3-4 (mm) Slitting accuracy :±0.3, ±0.5, ±1 (mm) Unit speed : 40, 60, 80, 100 (M/min) |

|

![]() Process Flow of Thin Plate Slitting Line Machine

Process Flow of Thin Plate Slitting Line Machine

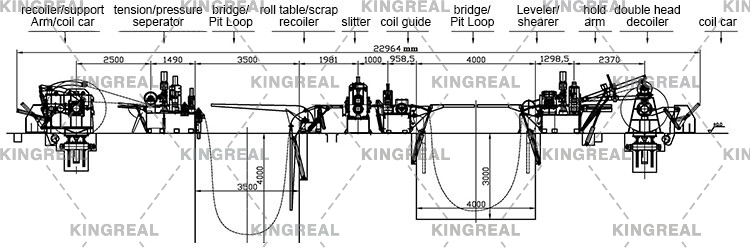

Loading Trolley -- Decoiler -- Roller Feeding -- Loop -- Slitting -- Waste Wire Machine -- Loop -- Separator -- Winder -- Unloading Car

![]() Features of Thin Plate Coil Slitting Machine

Features of Thin Plate Coil Slitting Machine

| 1. It is used to uncoil, slit and rewind the metal coil into a coil of the required width. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating. 2. For users with high requirements, which can be selected to automatically edge or center the material, which not only facilitates feeding, and improves work efficiency, but also improves cutting accuracy and protects the sheet. You can also choose automatic edge control to ensure the uniformity of winding ,especially for wide material winding. 3. The production line is mainly composed of feeding trolley, uncoiler, traction leveling machine, shearing machine, slitter, waster edge winder, tension mechanism, winder, unloading device, etc. 4. The equipment has a high degree of automation, simple and reliable operation, high work efficiency, fast production line speed, and self-matching uni speed. |

|

![]() Reference Data of Slitting Coil

Reference Data of Slitting Coil

|

Thickness |

Width |

Roll weight |

Finished width |

Shearing velocity (MAX) |

Floor space; L*W |

|

0.15-2 |

800-1600 |

30T |

≥20mm |

200m/min |

25*10 |

|

0.5-4 |

800-1600 |

30T |

≥40mm |

120m/min |

25*10 |

|

1-6 |

800-1600 |

30T |

≥60mm |

80m/min |

25*10 |

|

2-8 |

800-2000 |

30T |

≥70mm |

60m/min |

30*11 |

|

3-10 |

800-2000 |

30T |

≥80mm |

50m/min |

35*11 |

|

3-12 |

800-2000 |

30T |

≥100mm |

40m/min |

35*11 |

|

3-14 |

800-2000 |

35T |

≥100mm |

40m/min |

36*11 |

|

3-16 |

800-2000 |

35T |

≥120mm |

35m/min |

36*11 |

|

5-20 |

800-2000 |

40T |

≥120mm |

30m/min |

38*11 |