KINGREAL Heavy Gauge Precision Slitting Machines are specifically designed for slitting high-strength, thick-gauge materials.

This slitting line is capable of processing different materials such as cold rolled steel coils, hot rolled carbon steel coils, stainless steel coils, copper, brass, aluminum and etc..

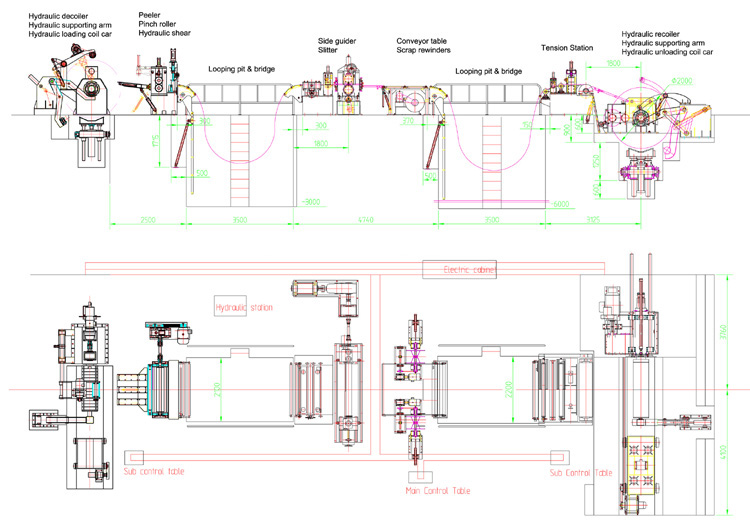

![]() Description of Heavy Gauge Slitting Line

Description of Heavy Gauge Slitting Line

Kingreal is a veteran coil slitting machine manufacturer in China. The Heavy Gauge Precision Slitting Line produced by Kingreal is for slitting the heavy gauge and high-strength material to narrow strip and rewinding to coil. We manufacture top quality Slitting Machines for the converting industry.

Our coil slitting line will reduce your labor costs with our high tech automation system. Your production and product quality will improve with burr-free and precision cuts. Our experienced project team will design your slitting line to suit your needs, including line automation.

| Model No. | RS 3.0-12.0 | RS 4.0-16.0 | RS 6.0-20.0 |

| Coil Material | CR Coils , HR Coils, S.S Steel Coils, GI Coils, AL Coils, Copper Coils Picking Oil Coils | CR Coils , HR Coils, S.S Steel Coils, GI Coils, AL Coils, Copper Coils Picking Oil Coils | CR Coils , HR Coils, S.S Steel Coils, GI Coils, AL Coils, Copper Coils Picking Oil Coils |

| Coil Thickness | 3.0~12.0mm | 4.0~16.0mm | 6.0~20.0mm |

| Line Speed | 0~60m/min | 0~50m/min | 0-50m/min |

| Coil Weight | ≤30T(35T) | ≤30T(35T) | ≤30T(35T) |

| Coil I.D | φ508,φ610,φ760mm | φ508,φ610,φ760mm | φ508,φ610,φ760mm |

| Coil O.D | ≤φ2200mm | ≤φ2500mm | ≤φ2500mm |

| Strip Width | ≥100mm | ≥100mm | ≥100mm |

| Number of Strip | 5~20 | ≤5 | ≤5 |

| Slitting Accuracy | ±1.0mm | ±1.0mm | ±1.0mm |

| Blade shaft | Ф320 | Ф340mm | Ф360mm |

| Electrical Control System | PLC Automatic control | PLC Automatic control | PLC Automatic control |

![]() Compatible with Diverse Material

Compatible with Diverse Material

|

1. Cold rolled or hot rolled steel 2. Galvanized steel, pre-painted 3. High strength steel 4. Stainless steel 5. Aluminum 6. Copper 7. Zinc 8. Alloy |

|

1) High-speed cantilever uncoiling mechanism, using the ground to uncoil, reducing the pain of digging a pit.

2) The use of spacer type round shear, in this round shear can also be installed in the locking type blade, for dual-use round shear.

3)Adopt our newly developed double-edged cutting head device, which is small in size and fast in cutting speed.

4)Adopting air bag type pressing to ensure the tension to keep the balanced tension in different thicknesses.

5)Adopt our new patented technology taper tension anti-scratch tension mechanism control system, which solves the problem of tension scratches and winding characteristics.

6)Adopt the horizontal drive winding mechanism newly developed by our technical team, which solves the problem of gear lubrication of winding mechanism.

![]() FAQ

FAQ

1. How do you do quality assurance?

We have a dedicated team to do strict QA, every machine, part and dimension will be inspected and tested to make sure it is within the tolerance.

2. Why should I choose you, and what makes you different from other Chinese suppliers?

We have specialized in metal processing industry for over 20 years.

Our metal processing machines are exported directly to Russia, Vietnam, India, Indonesia and many other countries in Asia, Africa, Middle East and South America.

3. How can we guarantee the quality?

We always test and adjust our machines before shipment; if needed, we also send samples of our machine production to our customers for confirmation.

4. What can you buy from us?

Various types of metal processing machines, such as metal slitters, cut to length machines, metal ceiling tile production lines, perforation punching machines, decoiler leveler feeder equipments, and diverse roll forming machines.

![]() KINGREAL Technical Team

KINGREAL Technical Team

KINGREAL has a professional technical team with more than 20 years of relevant experience from the drawing design to the manufacturing of Coil Slitting Machine, from design - production - installation - after-sales, our team has an excellent standard.

We have established a localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India etc. Localized service points in other countries are also in progress.

![]() Kingreal Factory

Kingreal Factory

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!