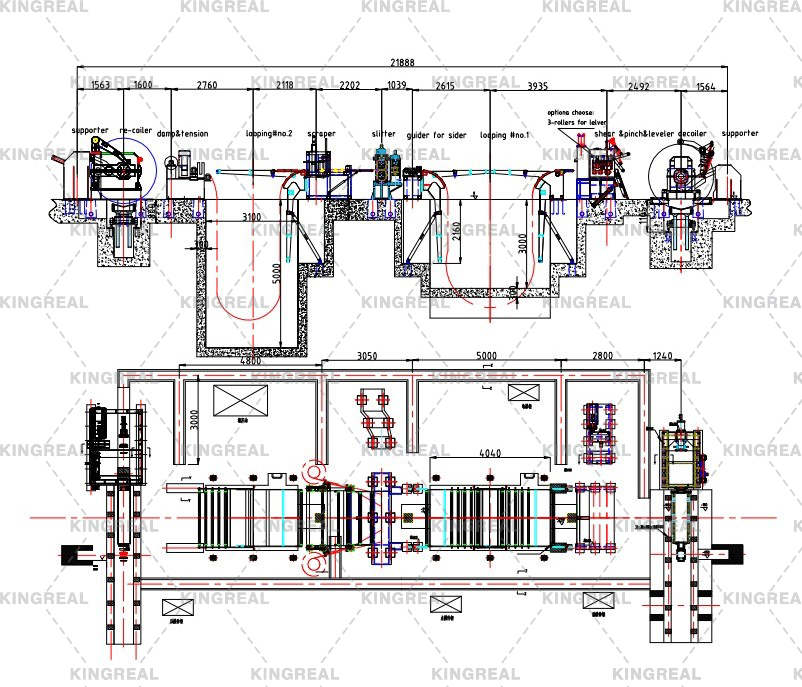

Silicon Steel Sheet Slitting Line Machine can slit silicons steel coil into certain width. KINGREAL is a professional manufacturer of metal coil process equipment in China, send us your production requirements and we will send you the machine production plan and quotation you need.

| Material | Silicon(other can be customized) |

| Coil Thickness | 0.3-3mm |

| Coil Width | 500-1600(Max) |

| Max Coil Weight | 20 T |

| Slitting Machine Speed | 0-220m/min |

|

Unwinding.

1. The loading table can be pre-packed with multiple rolls to improve the working efficiency.

2. This slitting line uncoiling unit adopts a hydraulic collapsible roller, no harm to the bottom layer of material. It can be stretch uncoiling or manual unloading, effectively preventing the material from deflection and scratching.

Slitting. 1. The slitting head mandrel is fixed in the eccentric sleeve. If the blade is just polished, the slitting angle remains the same. 2. The slitting line has two slitting heads. While one is running online, the other can be set up for equipment, which can greatly eliminate production downtime. 3. Hydraulic lock nut is used for higher accuracy of blade positioning. |

|

| Tensioning.

1. The tensioning unit is equipped with two pre-separation devices. The separation axis can be removed laterally for faster spacer switching. 2.

2. With frictional tensioning table. Adjustable tension can be provided by hydraulic or pneumatic. 3.

3. Our slitting lines can also be equipped with a roller type tightener, which is suitable for materials with coated surfaces, as it does not damage the coated surface. Winding machines. 1. The slitting line can be equipped with a seamless hydraulic retractable winder, which does not damage the material substrate. 2. The clamping device has stress-reducing characteristics. For different thicknesses of the sheet, the roundness of the reel remains the same. 3. Coiling is firm, dense and neat. |