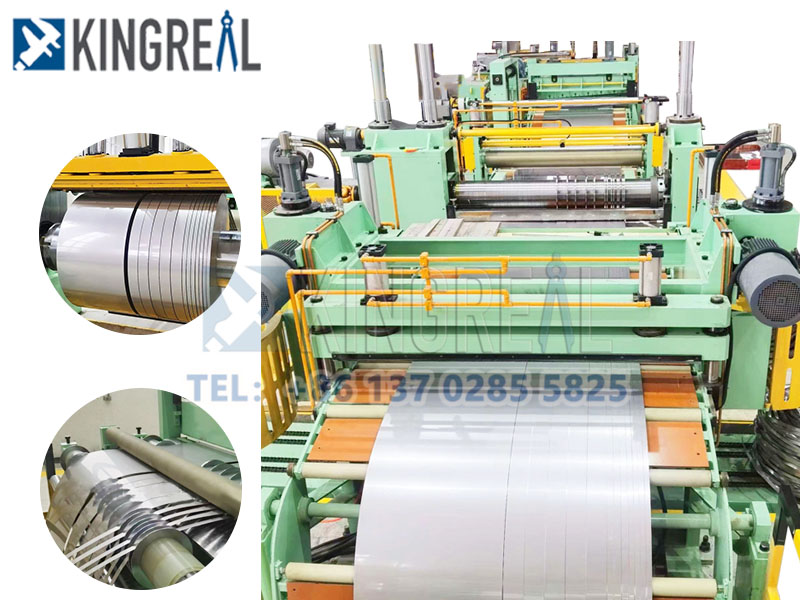

KINGREAL is a professional coil slitting machine supplier, Stainless Steel Coil Slitting Machine is one of our best-selling coil slitters. The stainless steel material can be cut into specific widths according to the needs of customers, and rewind into small rolls.

![]() Description of Steel Coil Slitting Line

Description of Steel Coil Slitting Line

KINGREAL Steel Coil Slitting Line is a superior equipment for stainless steel cutting and slitting. KINGREAL has rich experience in coil slitting, which can ensure the accuracy and speed of stainless steel coil slitter when cutting materials, and has won the affirmation and trust of customers.

KINGREAL steel coil slitting machine is advanced and robust in design to accommodate stainless steel coils of all sizes. It can be easily adjusted to cut stainless steel coils to the desired thickness. Ensure the precision and speed of web slitting.

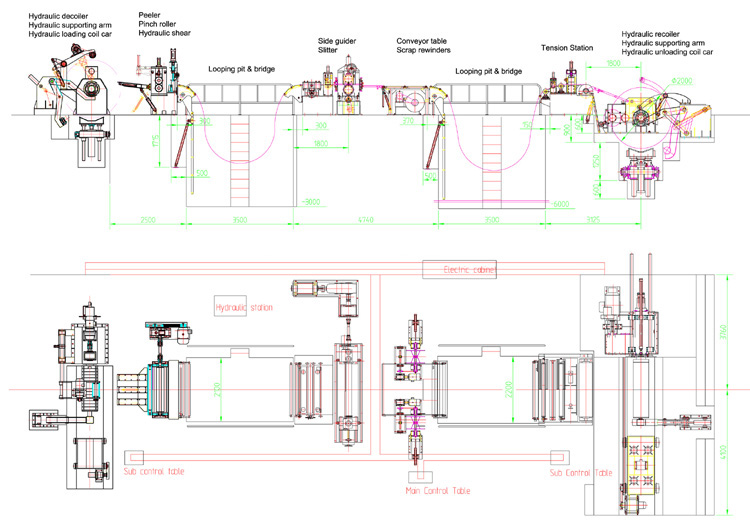

![]() Main Process of Steel Coil Slitting Line

Main Process of Steel Coil Slitting Line

Coil loading Trolley → Hydraulic Decoiler → Pinch Straightener → Pit Loop → Coil Side Guider → Guide Align / Disc Slitting → Side Scrap Collector → Pit Loops → Tensioner → Rewinder Machine → Coils Unloading → Finished Products

![]() Main Features of Steel Coil Slitting Machine

Main Features of Steel Coil Slitting Machine

| - Adopt the airbag type pressing to ensure to keep the balanced tension in different thicknesses. - The steel coil slitting machine has adopted PLC control, featuring a high degree of automation, high shearing precision, good slitting quality and a wide range of applications. |

|

![]() Steel Coil Slitting Line Structure Components

Steel Coil Slitting Line Structure Components

| List | Equipment Name | Qty |

| 1 | Optional Coil Load Trolley | 1 Unit |

| 2 | Hydraulic Decoiler | 1 Unit |

| 3 | Hydraulic Assist Support | 1 Unit |

| 4 | Loop Bridge | 1 unit |

| 5 | Guide Align & Main Coil Slitting Machine | 1 unit |

| 6 | Scrap Collector | 1 unit |

| 7 | Loop Bridge | 1 unit |

| 8 | Hydraulic Tension Station | 1 unit |

| 9 | Hydraulic Assist Support | 1 unit |

| 10 | Vertical Press Arm Hydraulic Recoiler, Pushing Device | 1 unit |

| 11 | Hydraulic System | 1 unit |

| 12 | Electrical Control System | 1 Set |

![]() Specifications of Steel Coil Slitting Machine

Specifications of Steel Coil Slitting Machine

|

Applicable material |

Carbon steel/Stainless steel |

|

Thickness (mm) |

0.3-2.5 |

|

Width (mm) |

500~1800 |

|

Inner diameter (mm) |

φ508/φ610 |

|

Outer diameter (mm) |

≤φ1800 |

|

Roll weight (tons) |

≤25 |

|

Width accuracy (mm) |

≤±0.05 |

|

A maximum slit (pcs) |

≤35 |

|

Speed |

≤200m/min |

|

Capacity |

≤258KW |

![]() Optional Choice

Optional Choice

| 1. Dual slitter head To maximize the slitting speed, you can equip a double slitter head in your steel coil slitting line is convenient for you to slit the metal coil into different thicknesses or widths. In this way, high-precision, high-efficiency performance is achieved. |

|

|

2. Protective shield You also can equip a protective shield in your steel coil slitting line. The protective cover can isolate dangerous parts of the machine and avoid direct contact with operators, thereby preventing operators from being injured during use. |

![]() Application Of Stain Steel Coil

Application Of Stain Steel Coil

Stainless steel thin coils are widely used in various fields1. Here are some of the main fields:

Construction industry: Stainless steel coils are often used for exterior walls of high-rise buildings, indoor and outdoor columns, handrails, elevator sidings, doors and windows and other internal and external components. In addition, surface treatment of stainless steel plates, such as coloring and coating, can improve the decorative beauty and further expand the application field of stainless steel coils.

Water industry: Stainless steel coils are suitable for water industry equipment such as water production, storage, transportation, purification, regeneration, and seawater desalination. Its advantages include corrosion resistance, earthquake resistance, water saving, hygiene, light weight, less maintenance, and long service life.

![]() FAQ

FAQ

1. What are our advantages?

With more than 20 years of experience in manufacturing the coil slitting machines and we are a manufacturer.

So we can provide a strong and powerful service before and after sales.

2. How to visit your factory?

Our factory is located in Foshan City, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

We will pick you up at the station or airport.

![]() Kingreal Factory

Kingreal Factory

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!