Steel Coil Slitting Line Rewinding Machine

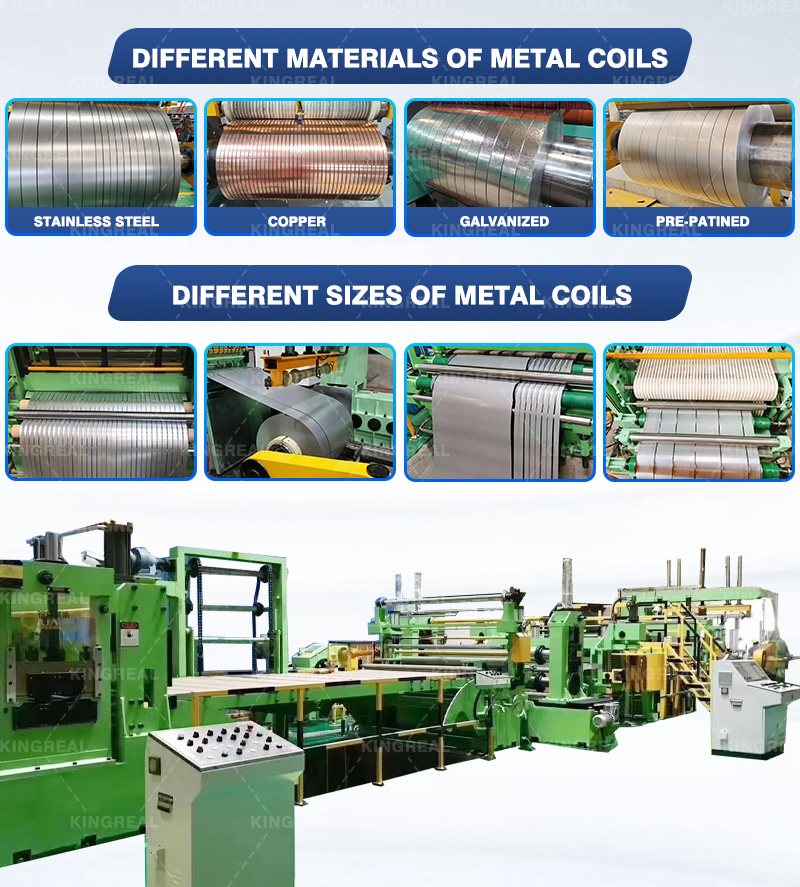

Kingreal produces and sells steel slitters and rewinders, which can form a complete metal coil slitting line. Kingreal‘s slitter rewinder machine is compatible with metal coils of different materials and thicknesses. The slitter rewinder machine has a sturdy structure, long service life, and adjustable speed. It is your first choice for slitting metal coils.