Feeding feature by PLC program from MITSUBISHI

Feeding feature by PLC program from MITSUBISHI

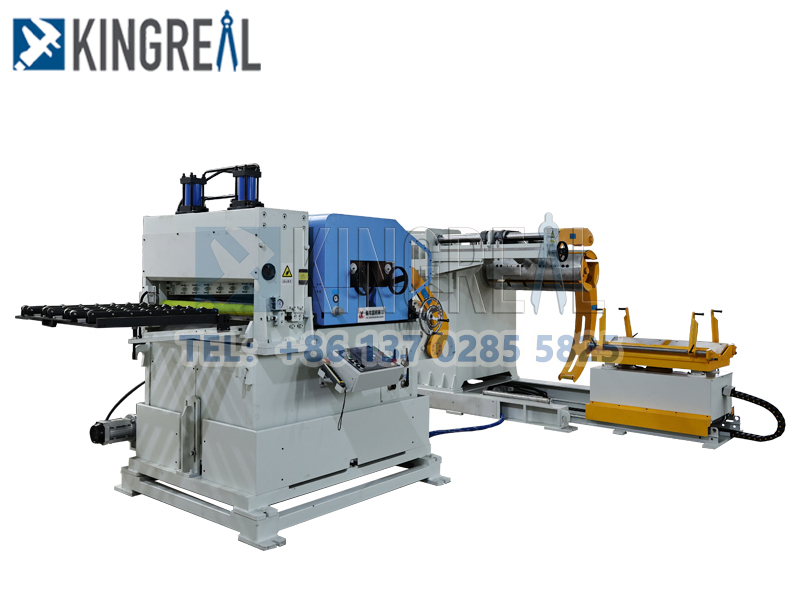

1.NC Servo feeding. Operating with Computerize Numerical Control by PLC program from MITSUBISHI made in Japan. The electrical parts from YASKAWA made in Japan including Servo motor, driver, encoder, interface screen and so on.