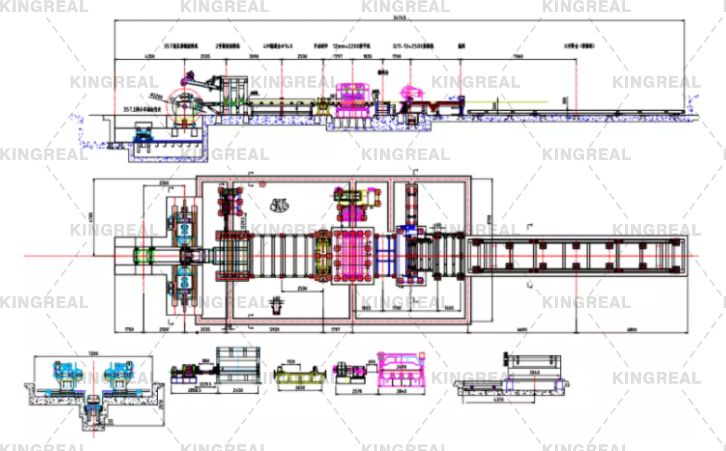

Cut-to-length lines process metal coils by uncoiling, straightening, shearing to length and stacking metal slabs. These lines provide automation to ensure accurate feeding, shearing and flattening for a variety of industries.

![]() description of coil cut to length line

description of coil cut to length line

KINGREAL is one of the leading supplier of constant length (CTL) production lines and steel producers. CTL lines process bundles of steel coils through a process of flattening, leveling and cross cutting.

KINGREAL studies each case to come up with a customized solution. Our CTL lines include different types of shears (start-stop shears, flying shears, rotary shears), depending on the customer‘s needs.

In addition, depending on the final application, KINGREAL offers the most convenient machines, such as high precision straighteners, stackers. Edge trimming can be combined. The line is centrally controlled by numerical control (computer) and has three major advantages of high automation, high productivity and high working accuracy.

Coil can be uncoiled, fed, leveled, edge cut, sizing, slitting, cross-cutting and stacking in one loading, which effectively reduces the labor intensity of workers and allows stepless speed adjustment according to the actual situation of users.

This cross-cutting line is used to uncoil the steel coil and cut it to a certain length after flattening it in a stop-start manner.

![]() Production Process of coil cut to length line:

Production Process of coil cut to length line:

Uncoiler → shovel device → flattening → accumulator → centering device → fixed length feeding device → cutting machine → conveying table → precision straightening machine → feeding rollers → stacking frame

Fully computer controlled with diagnostics, automatic coil feeder system and quality control

Suitable for carbon steel, exposed and non-exposed materials, stainless steel, painted steel, aluminum and other materials

![]() Steps to use:

Steps to use:

1. The first is to turn on the power, turn on the key switch on the control panel, and then press the oil pump to start, so you will hear the sound of the oil pump rotation.

2. Shear plate material must be noted is the gap adjustment, generally located on the side of the machine, according to the plate material 12% ~ 15% adjustment gap, the gap value can be read in the dial.

3. The backstop material adjustment are generally electric quick adjustment and manual fine adjustment, you can first use electric adjustment is the approximate size in the manual fine adjustment to your desired shear position.

4. Step on the foot switch until the plate material cut section in the release, otherwise the release will automatically lift in the middle.

![]() Performance characteristics of coil cut to length line:

Performance characteristics of coil cut to length line:

The whole machine is designed with reasonable structure, compact shape, high precision, high efficiency, flexible and convenient adjustment.

Functions: automatic detection of steel coil parameters, one key to coil, one key to take material, automatic alignment adjustment. Automatic switching of double palletizers, automatic detection and tapping, precise calculation, safety and reliability.

The manufacturing process of the whole machine is strictly in accordance with the standard specification of machinery, and the production of each component is tracked and controlled. Cooperation with famous manufacturers at home and abroad has introduced the first-class leveling line technology, which is developed and extended by the professional technical team on this basis to provide users with high quality and efficient automatic sheet processing equipment.

The bearings and slides of the main machine are imported brands, with advanced lubrication system, long service life

The electrical components are imported high-end brands, and the mechanical supporting parts are famous brands at home and abroad.

● Higher cutting accuracy

● Improved reliability

● Scheduled production

● Flexible machining options

● High-resolution graphic monitor for plant floor human-machine interface (MM) message processing and display

● Programmable function keys for specific tasks

● Cutting function can be selected in automatic or manual mode, and in automatic mode the system can operate in single step or continuous operation

● Keying mode for setting: cutting length, quantity, work number, parameter adjustment... Through nema type front panel

● The operator can select the special screen/menu named: job number, cutting length, quantity, parameter setting operation parameters

![]() FAQ:

FAQ:

1. Could you produce the shear line as per our specific requirements?

Yes, we are a professional manufacturer specialized in automatic shearing line

for 25 years, we have a strong design & technical team, we can design and manufacture as your requirements.

2. How to get an accurate quotation ?

Please provide us the detailed requirements, such as coil weight, material, width, processing precision etc.

3. What‘s the MOQ, warranty... ...

MOQ: 1 set.

Warranty: 12 months after the equipment run normally .

4. What can you do if the machine is broken?

Our machine‘s warranty period is 12months. if the broken parts can‘t repair, we can send the new parts to replace the broken parts, but you need to pay the express cost by yourself. if after the warranty period, we can through negotiation for solving the problems, and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes, please tell us the destination port or address. we have rich experience in transport.

6. You are a trade company or factory?

We are a Manufacturer.