The Cut to Length Line Machine can be used for uncoiling, straightening, measuring, cross-cutting and sizing, stacking and other operations. It mainly includes uncoiler, straightener, checker, shear, conveyor, stacker, hydraulic system, pneumatic system and electrical system, etc. The line can ensure accurate feeding and shearing.

The automatic cut-to-length line can cut large sized coils into sheets of a certain size as required. For specific needs, the length and cutting quantity of the coil can be set on the touch screen. The automatic fixed-length line adopts the servo motor to measure the length, which can ensure product accuracy.

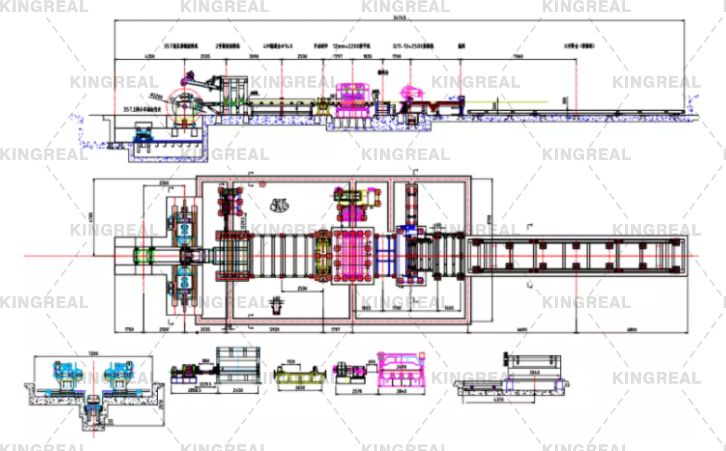

KINGREAL cut to length line including feeding trolley, decoiler, straightener, servo feeder, fly shearing machine, unloading table and automatic stacking table, etc,. The equipment configured in the cut to length line is not fixed, KINGREAL can produce customized production machines according to your needs.

![]() Component Advantage of CTL line:

Component Advantage of CTL line:

1. 7-inch large Mitsubishi touch screen control, with buttons and touch screen dual control mode. The screen instructions are clear and simple to operate.

2. PLC operation panel in an independent electrical box, completely avoiding the negative impact of punch vibration on feeding accuracy, ensuring high precision feeding.

3. Serrated CNC feeding machine has memory function. When the feeder suddenly loses power or needs to interrupt production due to special circumstances, there is no need to re-measure the program when restarting production. Simply press the reset button and it will run again. Simplify the operation procedure.

4. There are two types of relaxation: two ends relaxation and one by one relaxation. One machine can be used for different stamping processes.

5. Advanced automatic diagnosis system, when the operation is faulty, the system can self-diagnose and display the error information in detail.

6. It has two feeding methods, pointing and continuous feeding. It can be mixed operation, X-axis (single axis) can work independently, or X-axis and Y-axis can be linked, or both axes can be fed alternately. Save material cost.

7. High precision: In the process of continuous feeding, the minimum distance between the edge and the side can be set within 0.4mm, and the error of each movement can be guaranteed within ±0.05mm. Machine, hydraulic wire drawing machine, forming machine, laser cutting machine.

![]() Workflow

Workflow

Feeding trolley → uncoiler → traction head, pinch feed roller feeding → high precision leveling device → fixed length cutting → unloading table / automatic stacking table

![]() Main features of CTL line

Main features of CTL line

![]() Reference date:

Reference date:

|

Thickness(mm) |

Width (mm) |

Weight(Ton) |

Max sheet length (mm) |

|

0.2-2 |

100 - 750/1250/1600 |

10 |

1000/ 2500/3000 |

|

0.3-3 |

500 - 1250/1600 |

15 |

500-4000 |

|

0.5-4 |

500 - 1250/1600 |

15 |

500-4000 |

|

1-6 |

600 - 1250/1600 |

20 |

500-6000 |

|

2-8 |

600-1250/1600/2000 |

25 |

500-8000 |

|

3-10 |

600-1250/1600/2000 |

25 |

1000-12000 |

|

4-12 |

600-1250/1600/2000 |

25 |

1000-12000 |

![]() Kingreal Factory

Kingreal Factory

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!

1. Coil should be put right to keep the weight balance. The coil trolley must fix and tension the coil into the uncoiler before it can be reset.

2. Press the coil head with the traction roller first, then open the coil package to prevent the coil head from popping open.

3. When the machine is running, the operator must not stand on the coil.

4. Do not move the coil directly by hand.

5. Failure found immediately stop to check the unit. Only when it is checked and corrected, the machine can be restarted.

6. Do not remove or change the circuit. If you have any questions, please consult professional technicians.

![]() Why choose us?

Why choose us?

1. We can make and design all kinds of roll forming as well as shearing line machines according to customers‘ requirements.

2. It is a very perfect and durable machine. We have more than 25 years of experience.

3. This machine has the best quality and the best price. The measurement is accurate and easy to operate.

4. We can design and manufacture special models according to customers‘ requirements, and provide technical guidance, production, installation, commissioning and maintenance services for our customers.

5. Our products have been exported to many regions and have won high reputation for high quality and reasonable price