Cut To Length Line Machine is the right technical solution to ensure world-class quality of products in terms of flatness and dimensional tolerances.

![]() Description of the Metal Cut to Length Line

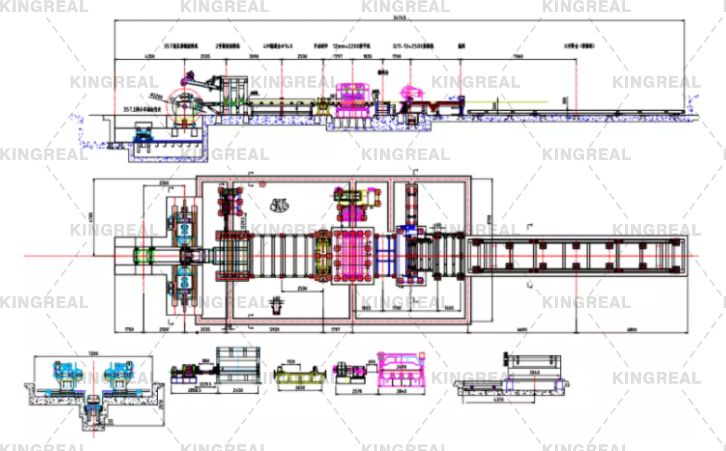

Description of the Metal Cut to Length Line

Electric plate shearing machine is the right technical solution to ensure world-class quality of products in terms of flatness and dimensional tolerances. The CTL machine line performs uncoiling, straightening, measuring, cross-cutting and length setting and stacking.

This line can ensure accurate feeding and shearing. It can be widely used for cold-rolled or hot-rolled carbon steel, tinplate, stainless steel and other kinds of metal materials with surface coating.

The fixed length line is controlled by PLC system. Information such as length, number of shears and speed can be input into the PLC system through the HMI (Human Machine Interface) touch screen.

The line will stop automatically when the required shearing volume is reached. The line speed is adjustable, high precision, automatic operation of the whole line, easy operation, and can produce flat and smooth plates.

![]() Workflow of Metal Cut to Length Line

Workflow of Metal Cut to Length Line

Unwinding - Guiding - Roll Forming - Measuring Length - Cutting - Panel to Product Rack

![]() Details Of Component:

Details Of Component:

1. Uncoiler

Loading capacity : 5T

Inner diameter: 470-530mm

Steel coil width: 914, 1000, 1220, 1250 mm.

Working speed: 0-15m/min, adjustable

According to your actual drawing.

2. Feeding Table

It is used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position,

to make sure the panel is neat and parallel.

3. Main Frame

Material 350 H steel

Feature more table, no shaking

4. Forming Rollers

Material High grade 45# steel.

Roller stations 3-6 stations. According to your actual drawing.

5. Cutting System

Material of blade Cr12MOV, much better than normal Cr12 material

Hydraulic power 3KW

6. Control Cabinet

Suitable power 380V, 50Hz, 3phase or according to your need.

Feature The whole process is automatically controlled by the computer. In this way, you can ensure the accuracy and easy work.

![]() Features of cut to length line machine

Features of cut to length line machine

- High degree of automation;

-Simple and reliable operation;

-High accuracy of fixed length;

-High flatness of sheet material

-Neat stacking.

![]() Safety operating procedures:

Safety operating procedures:

1. Work clothes are neatly worn, female workers should wear a good work cap.

2. Before driving, you must check whether the machine tool handle and running parts are normal.

3. The material should be carded and clamped, check whether the leveling and straightening equipment is opened simultaneously.

4. After the material is loaded, the center positioning should be measured and the hole distance should be checked to see if it is correct.

5. Must stop and change speed. When the machine is running, it is strictly forbidden to touch the material with your hands, not to touch the mold and motor with your hands.

6. The machine guide, the mold is strictly prohibited to put work, measuring tools and gloves and other items.

7. Do not leave the machine after the machine is turned on, to concentrate on the operation.

8. At the end of the day, wipe the machine, organize the site, cut off the machine power. Lubricate the machine gears.

9. During processing, if you find that the machine does not sound normal or malfunction, you should immediately cut off the power, diagnose the problem or notify the manufacturer.

![]() FAQ

FAQ

Q1: How can I know the design and proposal of the machine line?

Generally speaking, we need to know:

(1) Machine type: slitting line or cut to length line (normal CTL or flying CTL).

(2) Raw material info: such as thickness/width/master coil weight/coil ID/coil OD.

(3) Final product info: such as slit no’s (at thinnest and thickest)/min. strip width/precision and tolerance/exit coil ID, etc.

such as target length to cut, length tolerance, diagonal tolerance, etc.

4)Line speed: normal type or high speed type

5)Line type: normal type or compact design (for example, same function with single loop or double loops)

6)Electrical system: China mainland/Taiwan/Japan/European brands

7)Optional functions: such as paper collector/film coating/burr masher/digital display/special loading and unloading designs, etc.

Q2: How long will you send the proposal and offer?

We will need about 3~7 days to design the proposal upon collecting all details of the above-mentioned info necessary.

![]() Customer Visit

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!