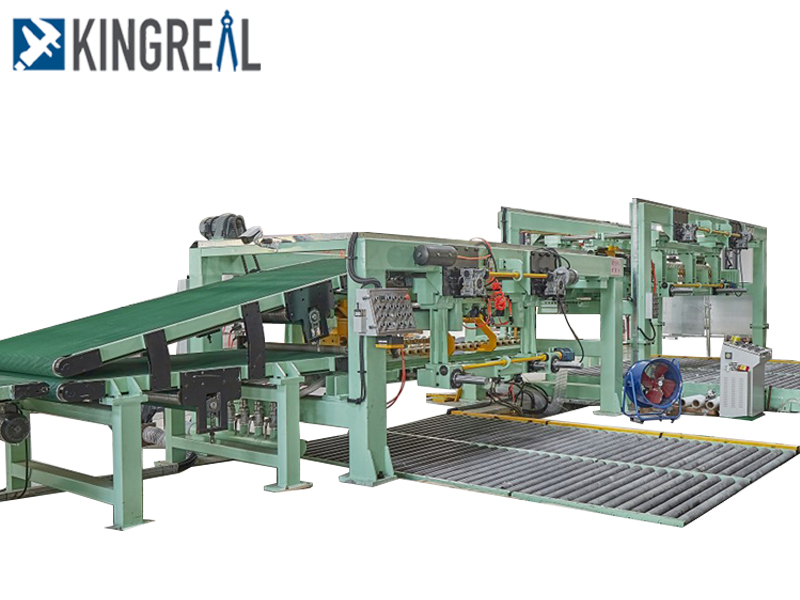

KINGREAL sheet metal cutter cut to length machine is mainly used to cut the coil to the specified size and stack the profiles, which process including decoiler, straightener, measuring and shearing.

KINGREAL sheet metal cutter cut to length machine is mainly used to cut the coil to the specified size and stack the profiles, which process including decoiler, straightener, measuring and shearing. This production line usually use the stainless steel, PPGI and aluminium etc, as the raw materials.

![]() Sheet Metal Cut to Length Machine Shipment

Sheet Metal Cut to Length Machine Shipment

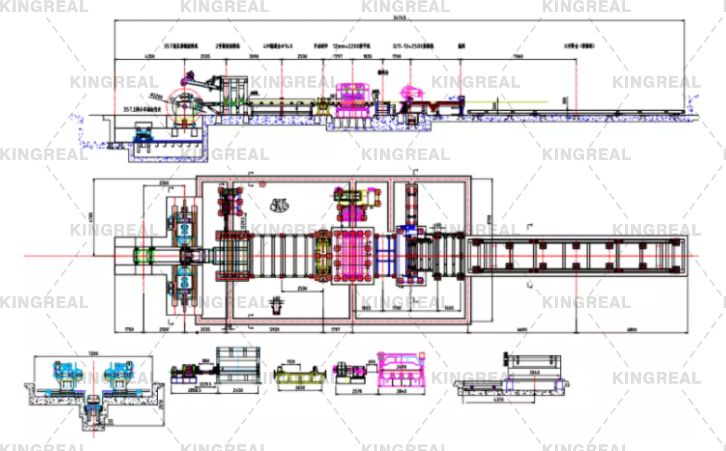

![]() Production Process:

Production Process:

Transport → loading → uncoiling → clamping initial correction → transition → guide pressing → leveling → sizing → cross-cutting → swing clamping drop → whole material → bundling and lifting.

![]() Such a line usually contains the following work procedures:

Such a line usually contains the following work procedures:

| 1. Unloading car (optional) 2. Unwinder 3. Shovel press device 4. Alignment facility 5. Pressing 6. Leveling (four high structure) 7. Length fixing 8. Shearing 9. Stacking (optional) 10. Electrical control system 11. Hydraulic control system |

|

![]() Components Detail:

Components Detail:

1. Decoiler Unit

This decoiler our sizing unit allows multiple strands of coils to be pre-positioned on the loading station. It is available with a single or double head to suit different requirements.

2. Straightener

Our cut-to-length line leveler can have different designs from 2H, 4H or 6H. It can be flexibly controlled for good leveling of the sheet.

Its leveling rolls are made of roll steel with chrome plated surface. It has good wear resistance and long service life.

3. Feeder and shear

Our cut-to-length lines use one or two pairs of feeding rollers, driven by AC servo motors, to feed the strip to the set length precisely.

They ensure fast positioning with minimal errors. These feed rollers are compatible with hydraulic shears or pneumatic clutch shears for fast cutting and easy gap adjustment.

They can be equipped with roller or belt conveyors.

4.Stacking unit

Our cut-to-length lines can be equipped with pneumatic or electromagnetic stacking units. It is equipped with a blower to protect the surface from scratching. Both longitudinal and transverse stacking are available.

![]() Reference Data :

Reference Data :

| Processing Thickness | 0.5~10mm |

| Processing Width | 600-2000mm |

| Cut to length Accuracy | ±1.5 mm |

| Cutting Speed | 10-70m/min |

| Coil Inner Diameter | 500/610 mm |

| Coil Outer Diameter | ≤2000 mm |

| Cut to Length Range | 500~4000mm |

| Sheet Leveling Flatness | ≤±1.5mm/m² |

| Length tolerance | ≤±1.5mm /2m |

| Diagonal tolerance | ≤±1.2mm/2m |

| Levelling precision | ≤2mm/m2 |

| Cut length | 500~3000mm |

(The data is only for reference , the actual need to be customized according to customer drawings)

In addition to the traditional Cut-To-Length line, KINGREAL also can customize the following special shearing machine:

![]() Special shearing machine more with other equipment to complete special purposes:

Special shearing machine more with other equipment to complete special purposes:

1. Cold-forming line shearing machine: such as automobile longitudinal beam cold-forming line, carriage side fender production line, color steel plate forming line and other production lines configured for special shearing machine, etc..

2. Steel structure production line shearing machine: mostly used for angle steel, H-beam automatic production line to complete the shearing process.

3. Plate flattening line shear: for plate uncoiling and leveling line, in order to match the production line speed shear requirements and designed for high-speed shear, thick plate line more hydraulic high-speed shear, thin plate line more with pneumatic shear; high-speed line with flying shear, continuous production, high efficiency.

![]() FAQ

FAQ

1. I am new in this field, do not know about the machine and do not know how to operate it.

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.

2. Do you have after-sales support?

Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are a trade company or factory?

We are a Manufacturer.

4. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.

![]() Sheet Metal Cut to Length Machine Installation

Sheet Metal Cut to Length Machine Installation

![]() KINGREAL in Exhibitions

KINGREAL in Exhibitions