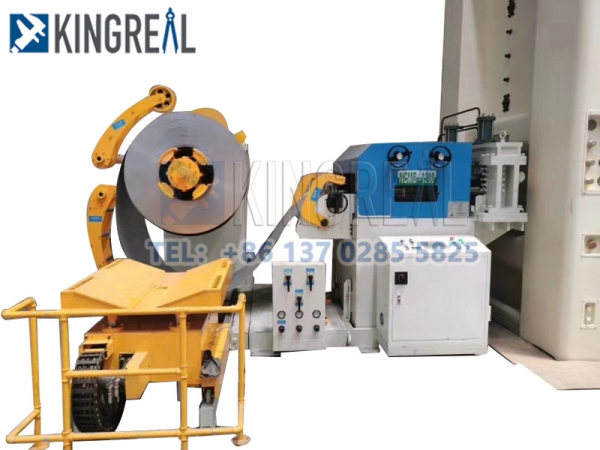

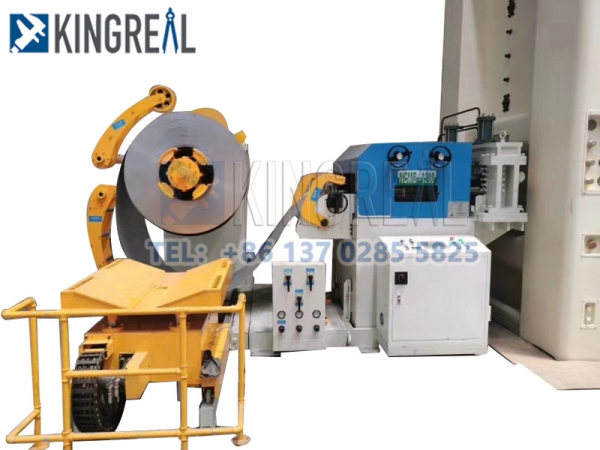

3 IN 1 Servo Feeder How to Carry Out Regular Maintenance

When using the 3-in-1 servo feeder, we must do a good job of routine maintenance in addition to regular maintenance. Why we need to perform regular maintenance and how to perform regular maintenance, the following KINGREAL will share with you.

The three-in-one servo feeder will inevitably have some problems such as wear and failure during long-term use. The purpose of regular maintenance is to detect problems in advance, extend the service life of the machine, and avoid serious consequences.

Which parts require regular maintenance? Let’s take a look:

1.Whether there is still grease in various drive gears, gear shafts, entrance width guides and other components. If there is insufficient grease, use a brush to apply grease. The grease used must meet the specified viscosity, and different types of grease cannot be mixed. Be careful not to mix impurities and moisture into the grease. Changes in the grease composition will cause a decrease in performance. Use clean grease.

2.The tension of the drive chain of the decoiler, the drive belt of the feeder and other components is corrected. Check the chain and belt for wear and damage. If damaged, replace them in time.

3. The multiple oil nozzles of uncoiler spindle need regular refueling.

4. Check whether there is air leakage in the air piping, if there is air leakage need to be replaced in time.

5.The dust and debris on the work roll and main operation panel need to be cleaned regularly by stopping the machine.

6.Check the thickness of the brake belt regularly. When the thickness becomes 2mm, replace the brake belt with a new one.

For our production safety and production continuity, we must strictly abide by operating procedures and perform daily and regular maintenance. KINGREAL have a professional technical team that can provide you with after-sales assistance.

If the equipment suddenly fails and shuts down during the production process, the operator must be calm. If you are not familiar with the equipment and do not know how to troubleshoot the fault, do not handle it without authorization. Please be sure to notify professional maintenance personnel or notify the manufacturer to assist in solving the problem as soon as possible. If the failure is due to operational reasons, the operator should learn from experience in time to avoid making the same mistake next time.

If the equipment suddenly fails and shuts down during the production process, the operator must be calm. If you are not familiar with the equipment and do not know how to troubleshoot the fault, do not handle it without authorization. Please be sure to notify professional maintenance personnel or notify the manufacturer to assist in solving the problem as soon as possible. If the failure is due to operational reasons, the operator should learn from experience in time to avoid making the same mistake next time.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima