What should be paid attention to when the shearing line is running?

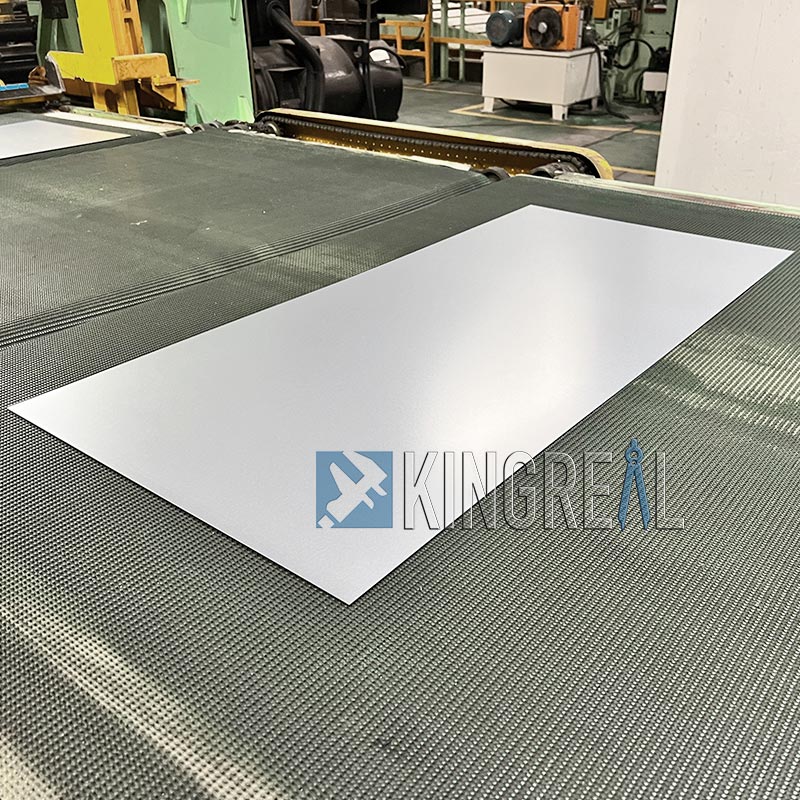

Cut To Length Machine is a kind of shearing equipment widely used in machining, which can cut steel plate materials of various thicknesses. Commonly used shears are divided into 3 types: Flat shear, Rolling shear and Vibration shear. Flat shears are used a lot.

Shears with a shear thickness of less than 10mm are mostly mechanical transmissions, and those large than 10mm are hydraulically driven. Single or continuous metal cutting is generally performed with foot pedal or button operation,.

When operating the Cut To Length Machine, you should pay attention to :

1. Before working, carefully check whether all parts of the shearing machine are normal, whether the electrical equipment is in good condition, and whether the lubrication system is smooth;

2. Do not operate the shearing machine by one person alone. 2-3 people should coordinate the feeding, control of dimensional accuracy and reclaiming, etc., and make sure that one person is under the unified command.

3. Adjust the scissors gap of the shearing machine according to the specified thickness of the shearing plate. It is not allowed to cut 2 sheets of different specifications and materials at the same time. It is not allowed to cut by stacking.

The sheared sheet requires a flat surface, and it is not allowed to cut narrower sheets that cannot be compressed.

4. The belts, flywheels, gears, shafts and other moving parts of the shearing machine must be equipped with protective covers.

5. The feeding finger of the shearing machine operator should keep a distance of at least 200mm away from the scissors mouth, and leave the pressing device.

The protective fence placed on the shear trigger cannot block the operator’s eyes from seeing the cutting part. The waste generated after the operation has edges and corners, and the operator should remove it in time to prevent being stabbed and cut.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima