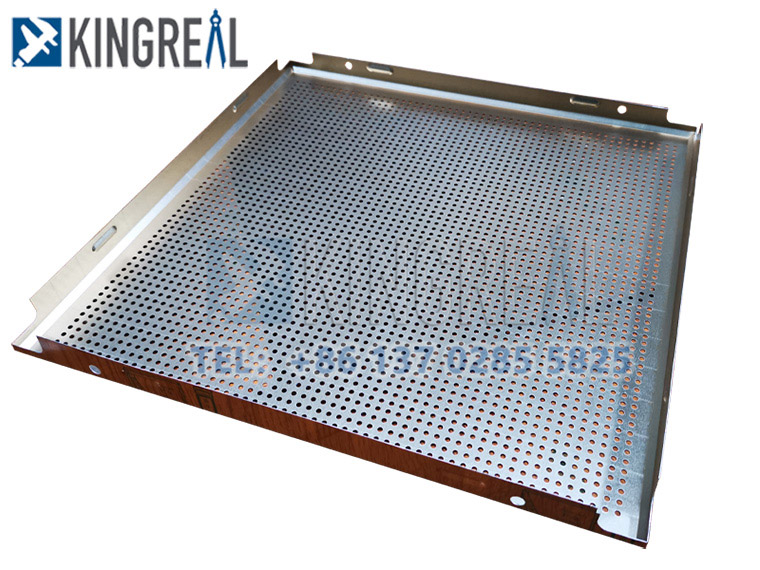

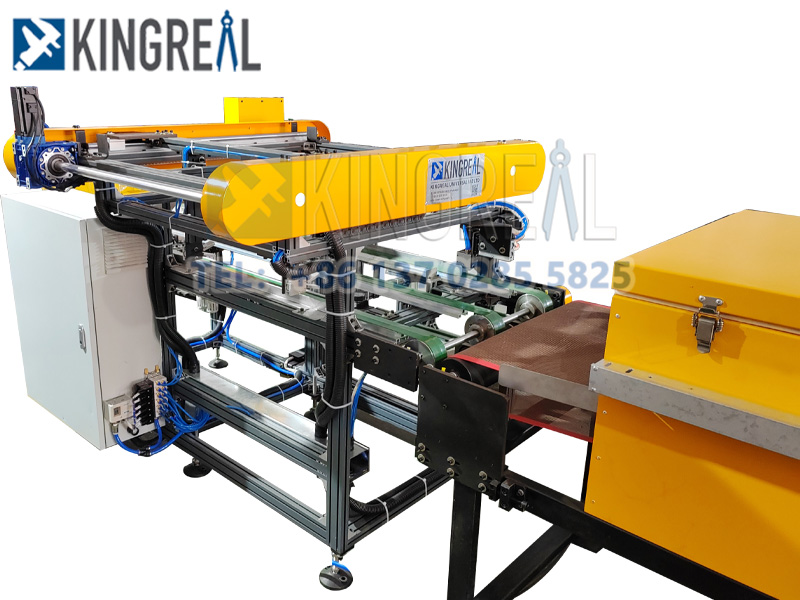

Acoustic Fleece Sticking Machine is for sticking a sound fleece on the back of the metal ceiling boards, which can greatly improved the sound absorbing performance. KINGREAL is a professional metal ceiling tile making machine supplier in China, and we have our own factory, can provide high quality machines for you. Welcome to contact us!

|

|

| Weight (KG) : 5000 Core Components : PLC, Motor Textile install speed : 10PCS/min Suitable perforated ceiling tile size : 600*600mm, 300*300mm or other size Voltage : 380 / 50 HZ / 3 PHASE |

|