- Combine decoiler & Leveler

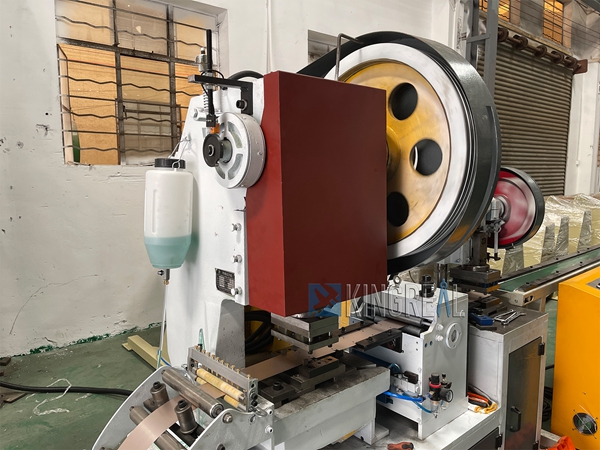

- Punching press machine

- NC servo roller Feeder

- Automatic cutting press machine

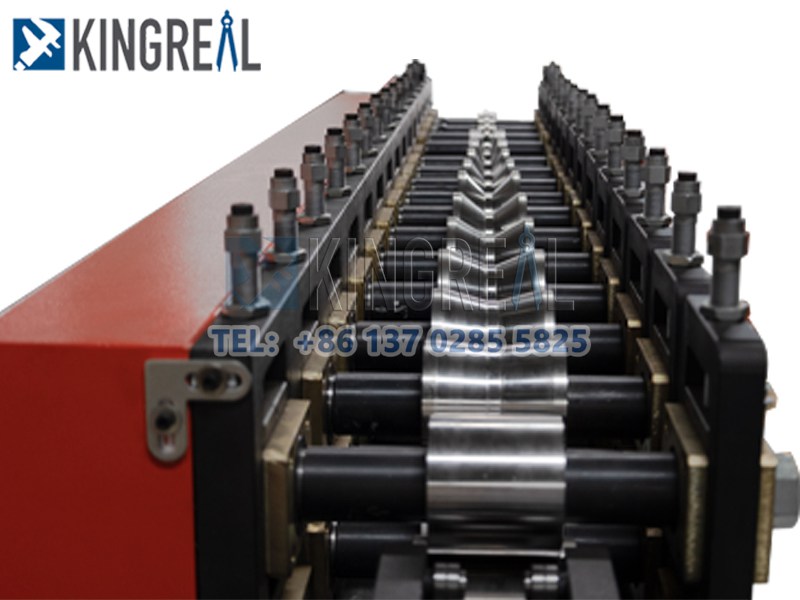

- Roll forming machine

- Finished product collector table

- Electric control panel

- Punching molds sets

- Cutting molds Sets

|

Machine Part |

Item |

Specification |

|

Material Uncoiler Part |

Motor Power |

380V 0.75KW |

|

Max. Loading Weight |

1Ton |

|

|

Max inner Diameter |

520mm |

|

|

Min. Inner Diameter |

450mm |

|

|

Machine Frame Material |

Channel steel and welded steel |

|

|

Max. Material Width |

200mm |

|

|

Operation Method |

Manual |

|

|

Hole Punching Device |

Punching Method |

Hydraulic Punching |

|

Hole distance tolerance |

±0.03mm |

|

|

Other Tolerance |

±0.3mm |

|

|

Material Feeding Method |

Feed drive servo motor |

|

|

Forming Machine |

Side Panel Type |

Wall Panel |

|

Motor Power |

380V 5.5KW |

|

|

Material of Roller |

Cr12 |

|

|

Side panel thickness |

22mm |

|

|

Reducer |

3# Cycloid Round |

|

|

Machine Frame Material |

Channel steel |

|

|

Roller set |

12 set |

|

|

Roller Diameter |

38mm |

|

|

Drive Model |

Gear |

|

|

Roller Material |

Aluminum Material 0.6mm |

|

|

Cutting and material collecting part |

Cutting Device |

Hydraulic Track CTL |

|

Length Fix Method |

PLC |

|

|

Cutting Model Material |

Cr12 MOV |

|

|

Cutting Method |

Hydraulic |

|

|

Material collecting table dimension (length*width*height) |

3M*0.7M*0.5M |

|

|

Material collecting method |

Manual collecting |

|

|

Machine Specification |

Control method |

PLC |

|

Production Speed |

7-12m/min |

|

|

Machine Dimension |

6*0.7 *0.7m(L*W*H) |

|

|

Gross Weight |

2.5 |

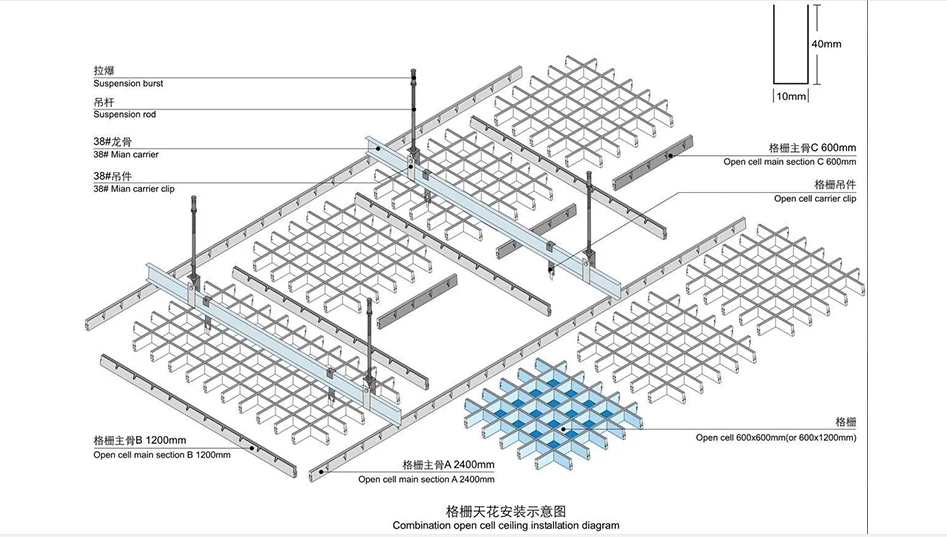

| This production line is featured with standarization and customization. It can produce standard sizes of open cell ceilings, also can be customized to produce other sizes as per requirement from clients. It adopts Gi steel or aluminum coils as raw material, with fast decoiling and straightening procedure. The whole open ceill ceiling production line is full-automatic type. |

|

|

With our high-speed punching press, perforation will be done accurately and precisely. This press features the open cell ceilings with quality perforation patterns and can be customized to punch other patterns as well. After perforation, material sheet will be conveyed by servo motor to main roll forming machine for final forming. We choose motor from famous brand YASKAWA to build this machine. |

| We equipped the open cell ceiling production line with high-quality main roll forming machine. Thick panel for strong structure, mold steel rollers for precision roll forming, archway architecture to build roller stations. This production line has been installed in many countries and won good reputation for us. Up to 14 stations will form semi-finished metal sheet into final open cell ceiling products. |

|