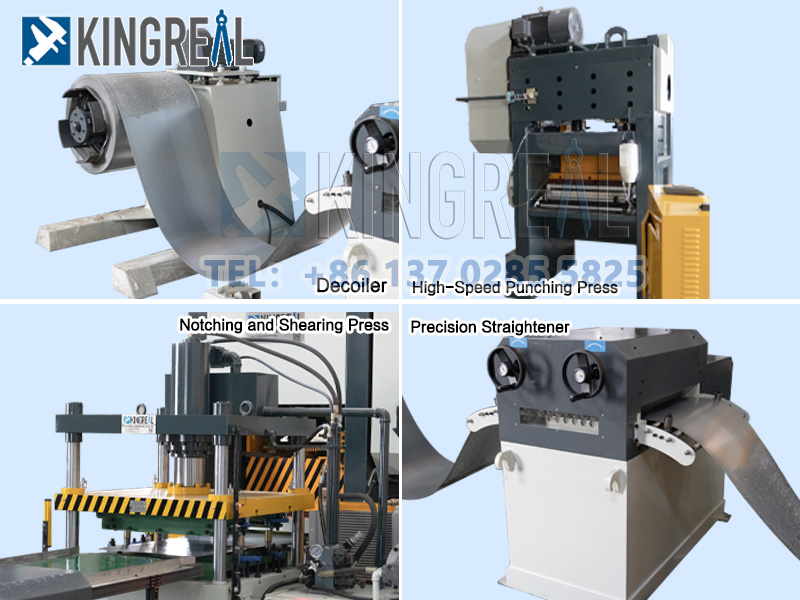

KINGREAL Metal Ceiling Tile Perforation Line is a kind of machinery and equipment specially used for processing ceiling punching, mainly including decoiler, leveling and perforate, which can meet different needs of customers.

| -Hydraulic Decoiler -Precision Straightener -Punching Press -Servo Feeder -Notching Shearing Press (Optional) -Product Output |

|

| 1.Diversity of Choice Our production line offers you a wide range of choices in various aspects: (1)Various tonnage presses are available (125Ton / 160Ton) (2)Compatible with different type ceiling (lay-in / clip-in) (3)Both aluminum and Gi steel materials is compatible with our production line |

|

|

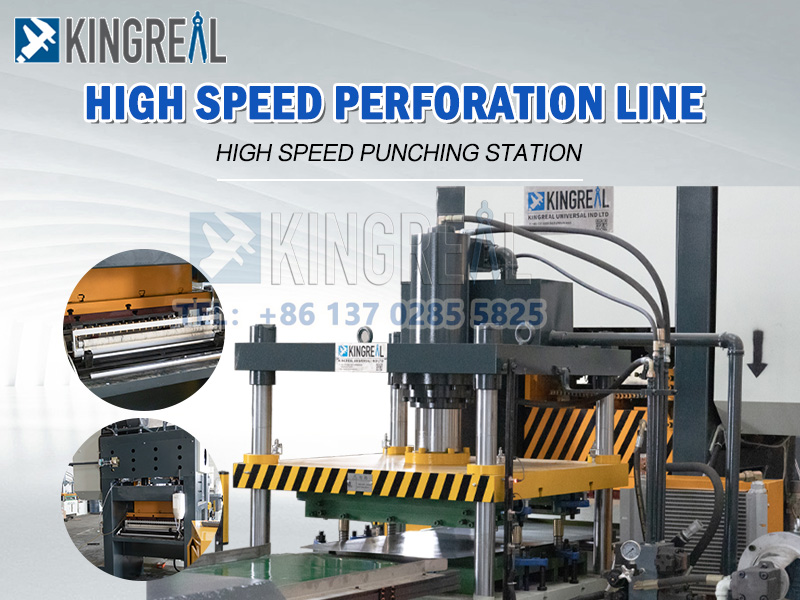

2.High Speed Production Line KINGREAL Metal Ceiling Tile Perforation Line is equipped with automated control system, realized the setting and adjustment of production parameters, as well as real-time monitoring and fault diagnosis of the production process. This automated control system is improved production efficiency and product quality. Our high speed production line realized: (1)180SPM perforation speed; (2) Production of 5 aluminum plates per minute and 3 iron plates per minute. |

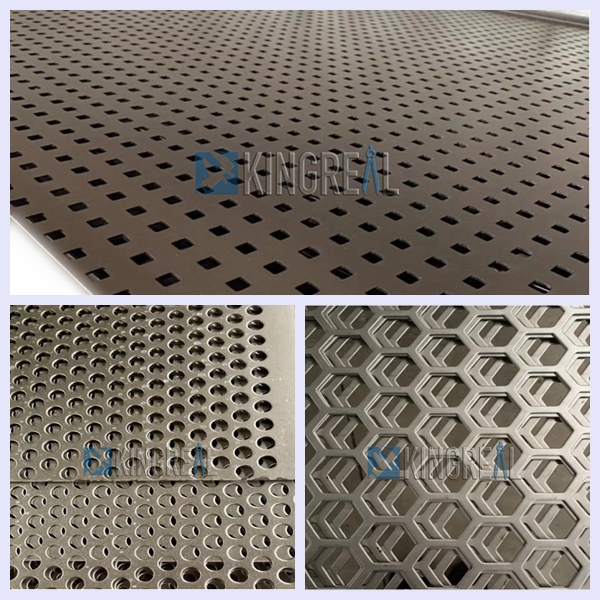

| 3.Meet Diversity of Production Needs Modern architectural design presents a diversified development trend. KINGREAL metal ceiling perforated line can fully cater to this trend. This line is mainly used for processing stainless steel, aluminum plate, aluminum alloy, steel plate, copper plate and other material punching, which can realize different types of punching processing, such as standard punching, special punching, round hole, etc. It can meet the customer‘s individual needs and diversity of production needs. |

|

| Maximum stamping width: | 1 . 25m |

| Punching speed: | 45-70 times/min |

| Maximum stamping thickness: | 2.0mm |

| Aspect: | 2500x1800x2000mm |

| Control way: | digital control |

| Power: | 7 . 5kw |

| Weight: | 5500kg |