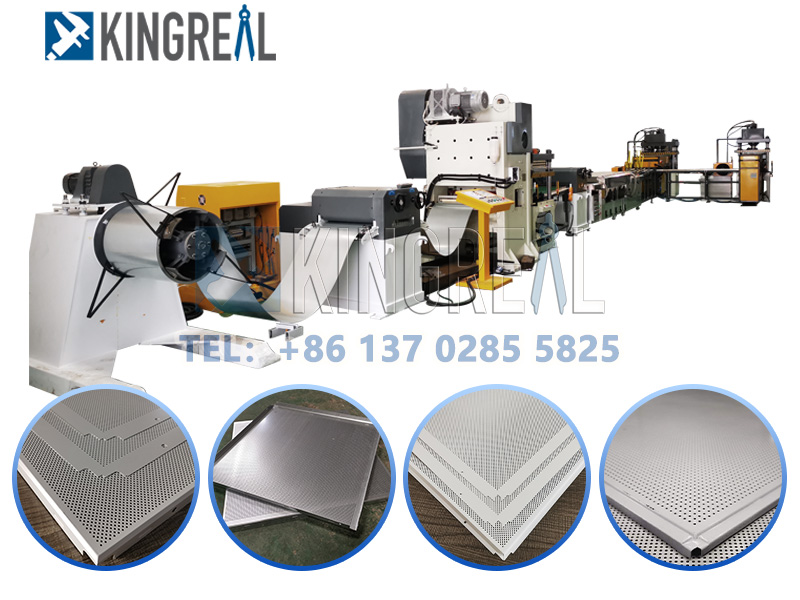

High Speed Full Automatic Metal Ceiling Perforation Production Line is one of Kingreal‘s best-selling production lines and has been successfully exported to Russia, Saudi Arabia, India, Argentina and other countries. The main features of this production line are high degree of automation, easy operation and high production precision.

Decoiler |

Precision Leveler |

Perforation Press |

Notching & Shearing Press Machine |

2nd Precision Leveler |

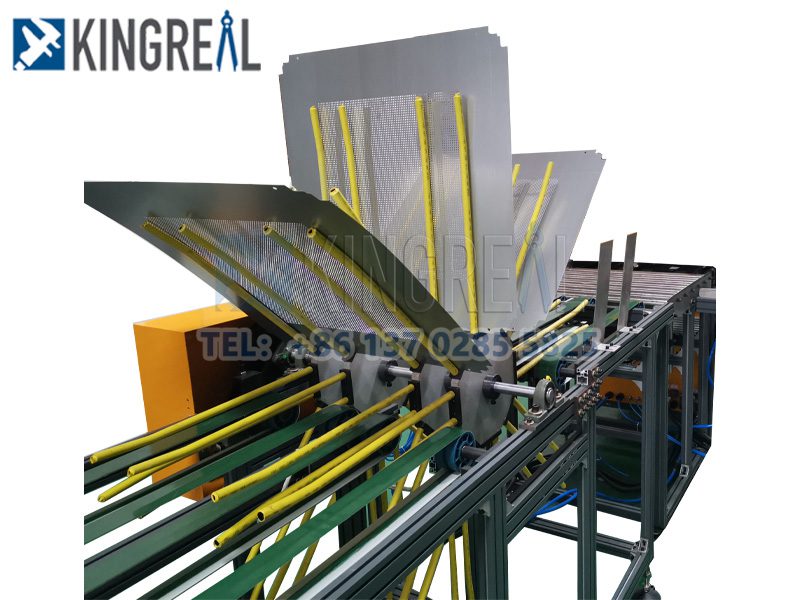

Auto Ceiling Tile Feeder |

Turn-over Machine |

Bending Forming Press |

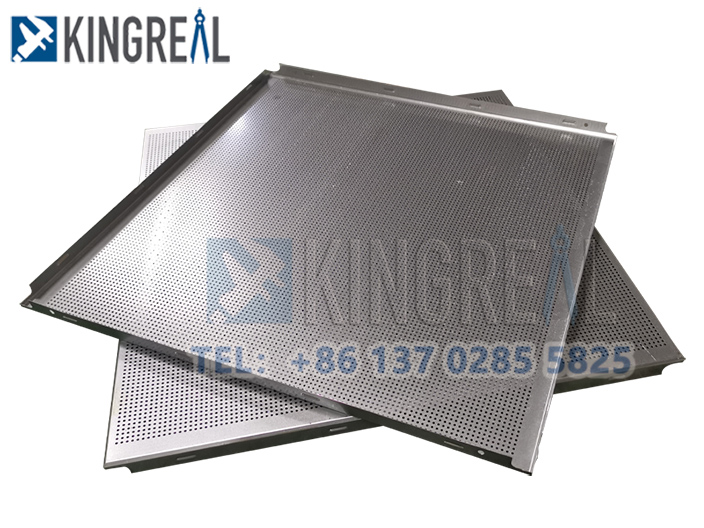

Finished Product |

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

| 1.Diversity of Choice Our production line offers you a wide range of choices in various aspects: (1)Various tonnage presses are available (125Ton / 160Ton) (2)Compatible with different type ceiling (lay-in / clip-in) (3)Both aluminum and Gi steel materials is compatible with our production line |

|

|

2.High Speed Production Line KINGREAL Metal Ceiling Tile Perforation Line is equipped with automated control system, realized the setting and adjustment of production parameters, as well as real-time monitoring and fault diagnosis of the production process. This automated control system is improved production efficiency and product quality. Our high speed production line realized: (1)180SPM perforation speed; (2) Production of 5 aluminum plates per minute and 3 iron plates per minute. |

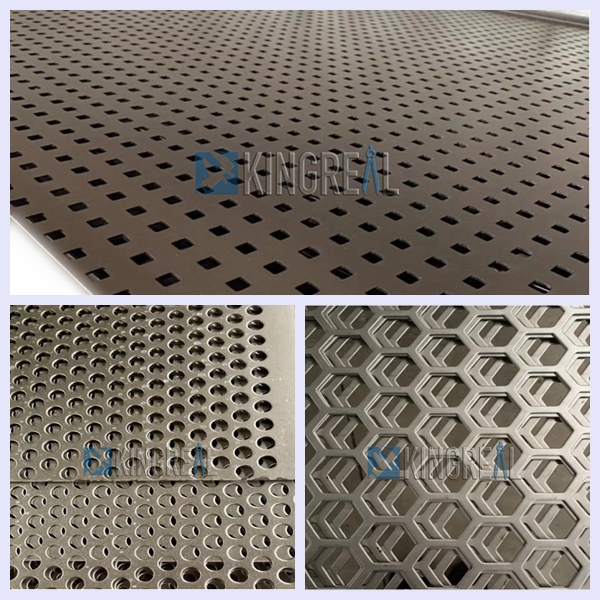

| 3.Meet Diversity of Production Needs Modern architectural design presents a diversified development trend. KINGREAL metal ceiling perforated line can fully cater to this trend. This line is mainly used for processing stainless steel, aluminum plate, aluminum alloy, steel plate, copper plate and other material punching, which can realize different types of punching processing, such as standard punching, special punching, round hole, etc. It can meet the customer‘s individual needs and diversity of production needs. |

|

| Acoustic Ceiling Tile Fleece Gluing Machine To upgrade the degree of sound absorbing, KINGREAL can provide a acoustic ceiling tile fleece sticking machine for you to gluing the fleece on the back of the metal ceiling panels automatically.

|

|

|

Metal Sheet Cleaning Degreasing Machine Machine

The oiling section is also optional, oiling of metal sheet can effectively protect its surface from corrosion and oxidation, and it can make the surface of sheet metal easier to clean and prevent dust and dirt from adhering. |

|