Main Components

Main Components

Decoiler - Straightener -- Servo Feeder -- Perforation Press -- Notching & Shearing Press Machine -- Bending Forming Press -- Products Stacking System

|

|

|

| Leveling Machine |

Punching Press |

Notching & Shearing Press Machine |

Optional:

Automatic Cleaning Machine -- Fleece Gluing Machine -- Automatic Turn-over Machine -- Automatic Mechanical Arm -- Re-Straightener

|

|

|

| Cleaning and Drying Machine |

Acoustic Ceiling Tile Fleece Sticking Machine |

Automatic Turn-over Machine |

Advantages of Main Components

Advantages of Main Components

1. Precision straightening machine and 2nd straightening machine

Kingreal equipped this fully automated ceiling line with two straightening machine. The first one is after the uncoiler, a 21-roller precision leveler machine can highly level the coil before starting the forming operation. The second straightening machine is after corner cutting press. After punching and cutting the corners, the drop ceiling panels tend to bend easily, so the second straightening machine is very important for the quality control of the metal ceiling tile panels.

|

Specification

Thickness of material : 0.3 - 2.2 mm

Feeding speed : 25m / min

Upper rollers : 9

Lower rollers : 10

|

|

2.Perforated Punching Machine

(1)Various choice:

①Able to achieve punching requirements of different shapes and sizes;

②Various tonnage presses available(125/160 ton)

(2)High speed:

The punching speed of kingreal standard perforated punching machine can up to180 SPM, which can produce aluminum panel 5-6pcs/min, iron panel 4pcs/min.

If you want to upgrade your production speed, kingreal also can provide a high-end version of punch press, which can speed up to 240 SPM, can produce aluminum panel 6pcs/min and iron panel 6pcs/min.

Specification

Output pressure force : 125 tons

Punching stroke : 20 mm

Aperture of holes : Φ 2.5

Adjustable thickness : 10mm |

|

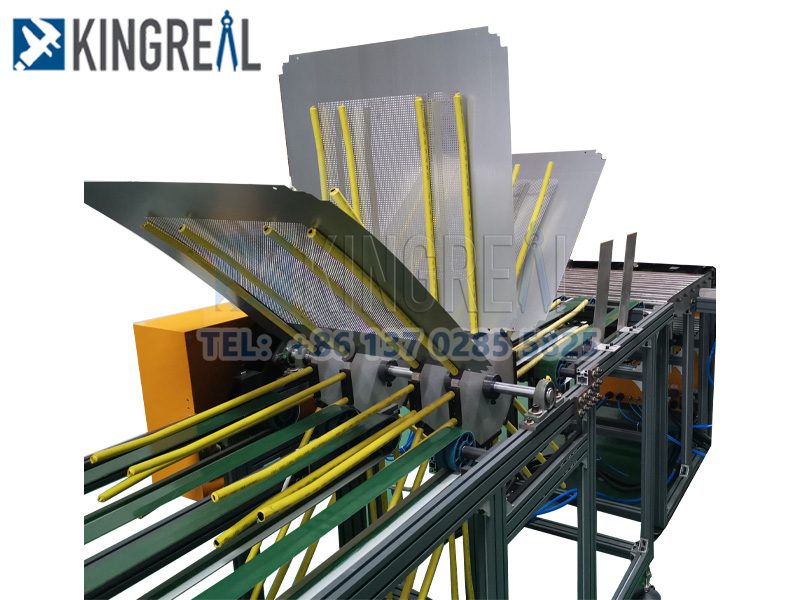

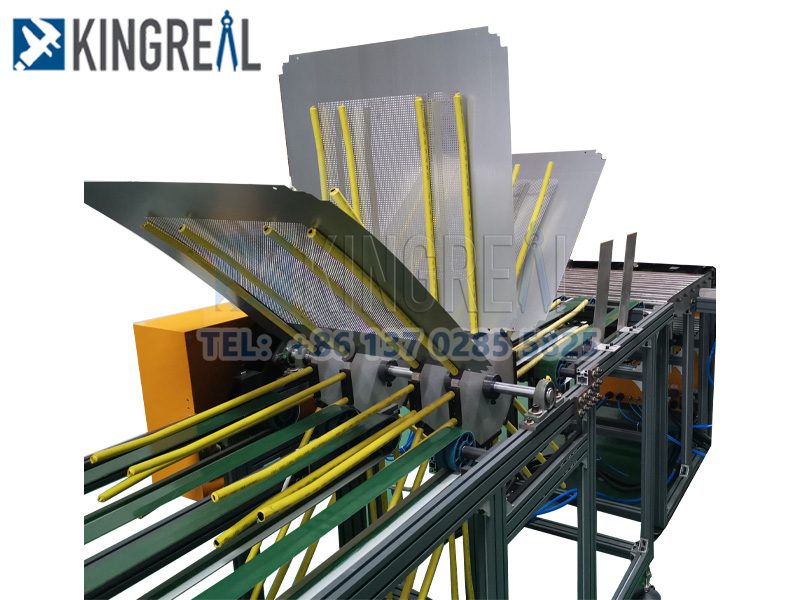

3. Notching And Shearing Press Machine

The notching and shearing press machine typically consists of a sturdy frame, a hydraulic or mechanical power source, and a cutting head with various cutting tools. The machine adopts four column oil press structure, and equipped a sharp cutting tool, which can be ensured the accurancy.

Specification

Cylinder pressure forcev : 60 tons

Cylinder stroke : 200 mm

Ground clearance of worktable : 850 mm

Machine size (W, L, H) : 2100 mm x 1100 mm x 2000 mm

Power consumption : 5.5 KW |

|

Customer Visit

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!

Kingreal in Canton Fair

Kingreal in Canton Fair