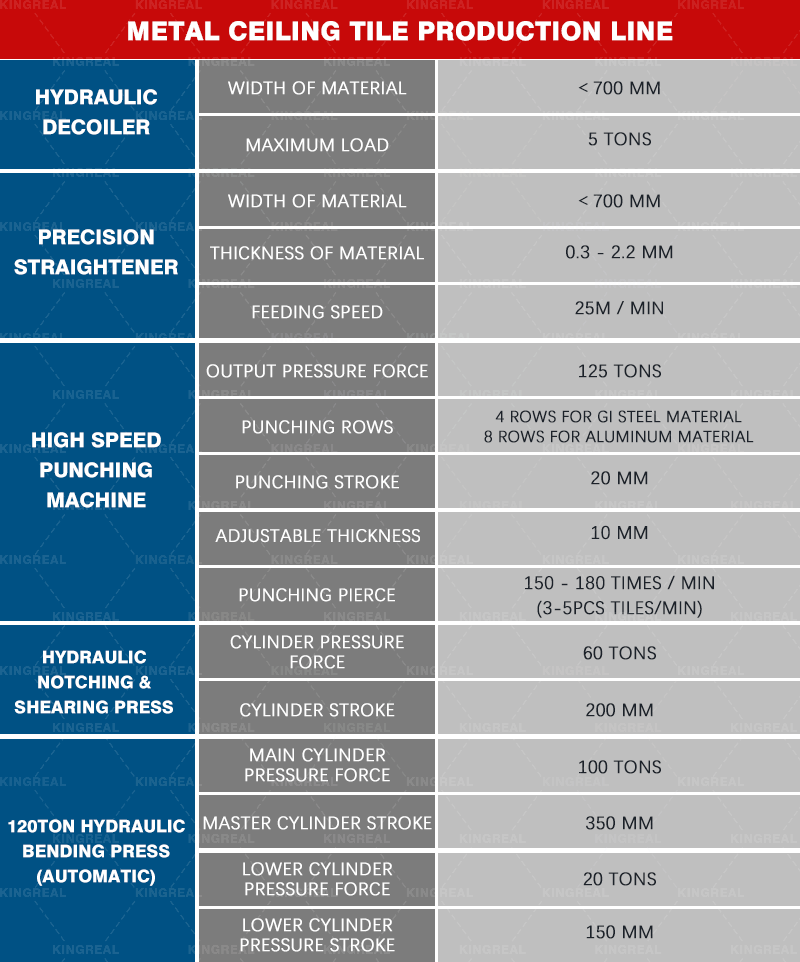

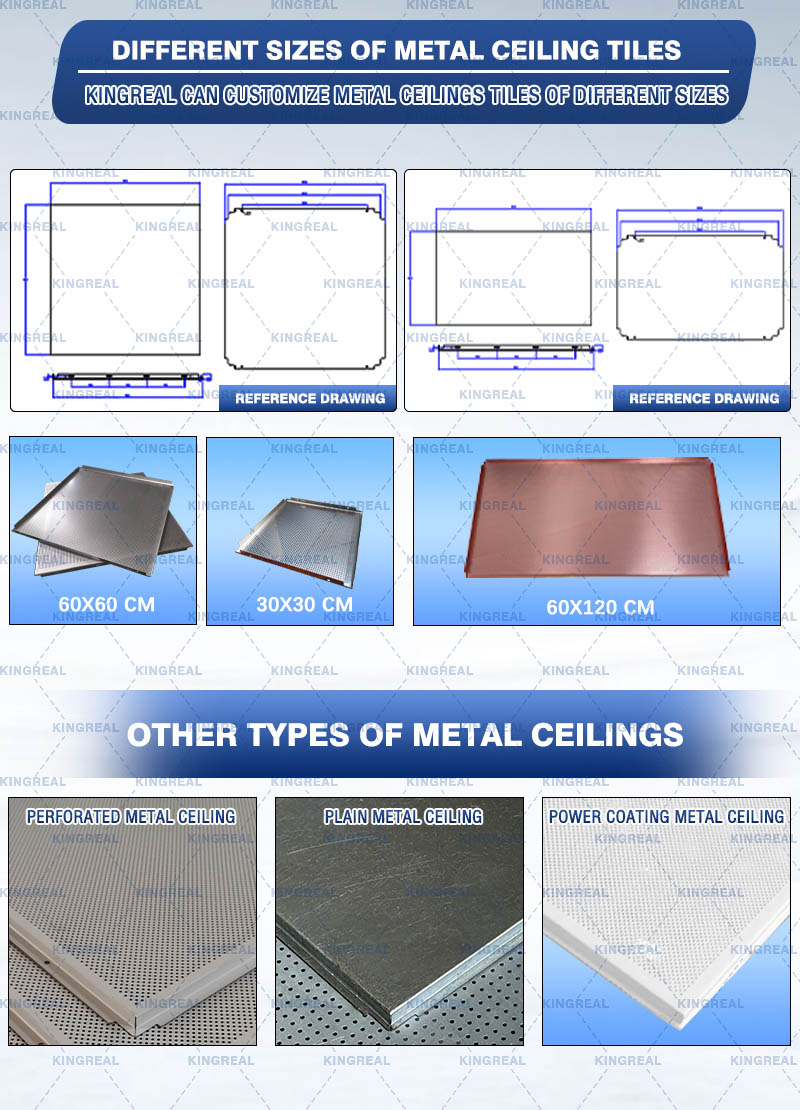

This 60X60CM ALuminum Ceiling Tile Production line is mainly used for the production of different kinds decoration ceiling tiles.

It adopt automatic material input, first flattening, holes punching, servo feeding, cutting to length, conveyor, second flatting, corner cutting and manual punch forming.

![]() Kingreal Suscessful Projects

Kingreal Suscessful Projects

| Hydraulic Decoiler&Precision Straightener Integration with Hydraulic Decoiler and Precision Straightener,reducematerial circulation between the two equipment processes. |

|

|

Perforation Press Machine 1.Various choice: ①Able to achieve punching requirementsof different shapes and sizes; ②Various tonnage presses available(125 / 160 ton) ③Able to produce different types of ceilings (lay-in / clip-in) 2.High speed: ①Punching speed:180 SPM; ②Production speed: aluminum panel 1min/5pcs ; iron panel 1min/3pcs |

| Washing and Drying Machine 1.Strong Cleaning Power:Using advanced automation technology and cleaning principles, the panel can be cleaned quickly and thoroughly to ensure its hygiene; 2.High Efficiency: The machine is fully automatic operation, greatly improving the work efficiency; 3.Integrated Washing and Drying: We equipped this cleaning machine with drying ovens. After cleaning, the panel will be automatically and quickly fed into the drying oven which make sure that sheets will not rust. |

|

|

Hydraulic Bending Forming Press 1.Fast and safe, with less material waste; 2.Manual operation:15PCS/min; automatic bending 10PCS/min; 3.Suitable for bending and forming of square metal ceiling tiles of different sizes; 4.By replacing different bending mold sets, metalay-in etc. |

| Auto Fleece Sticking Machine & Auto Drying Oven 1.Full Automatic:After bending forming, four mechanical hands quickly pull and spread the sound-absorbing cotton coated with glue to the ceiling; 2.Efficient and Safe:Replacing manual labor with mechanical hand to feed ceiling into machine, not only improve work efficiency, but also effectively avoid workplace injuries; 3.Sticking and Drying Integration:Equipped 2 auto drying ovens, it not only save many drying time but also improve marketing efficiency, because the acoustic ceilings can be packaged and go to market directly after drying. |

|

![]() Specification

Specification

![]() Different Metal Ceiling Tile Production Solution

Different Metal Ceiling Tile Production Solution

![]() Related Cases

Related Cases