![]() Specification

Specification

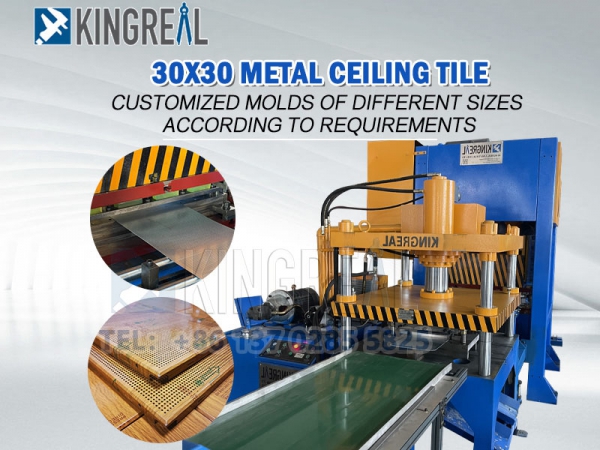

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons High-Speed Perforation Press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC Servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

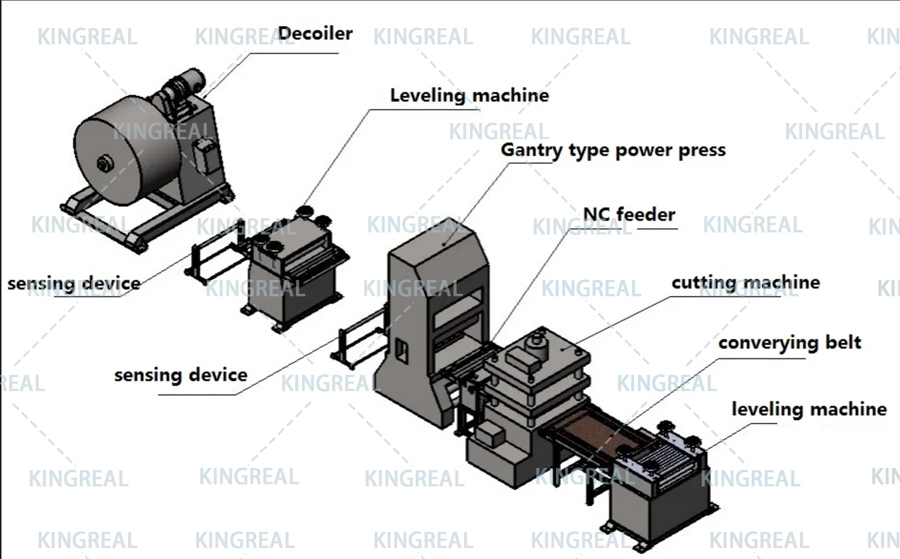

| Ceiling panel with perforation production line This production line focuses on the processing production for decorating ceiling. It consists of a series of procedures, decoiler, first time leveling. servo feeding, punching hook hole & hole arrangement, hydraulic cut-off device, conveying belt, second leveling, automatic feeding, hydraulic angle punching, manually stretching forming etc |  |

|

With this equipment, it can realize high machining precision, high processing speed, less operators etc. The equipment adopts servo motor by combining programmable PLC processor, some parts of which make use of Panasonic. Also, servo feeding is based on Yaskawa motor and all Schneider electric components. |

| The full automatical ceiling tile production line is used for producing different type of celing panels including full perforation ceiling plates and half perforation ceiling tiles, the types can be clip in, lay in, lay on and etc. |  |

![]() KINGREAL Installation Cases in Global

KINGREAL Installation Cases in Global

KINGREAL technical team in Russia

KINGREAL technical team in United Arab Emirates