Precision Leveling: It uses a four-high roller system to ensure high-quality leveling performance, suitable for various metals including steel, aluminum, and copper.

Widened Roller: The widened design of the support roller and the design of the bearings at both ends ensure the very precise concentric operation of the support roller and improve the operating rigidity of the leveling roller. In addition, the leveling lines on the part surface caused by the support rollers are greatly reduced.

Robust Construction: The design of 4-high leveling machine includes support rollers that ensure the leveling rollers can bear heavy pressure without bending, maintaining the equipment’s rigidity

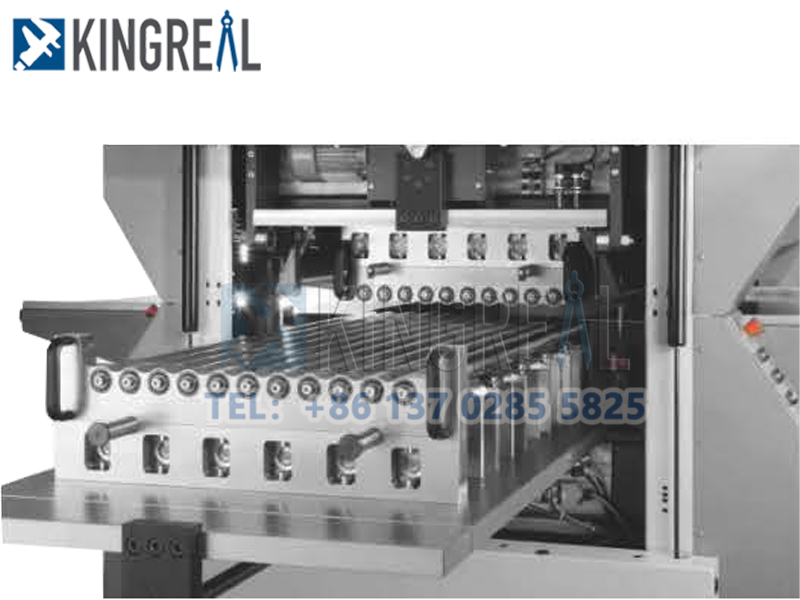

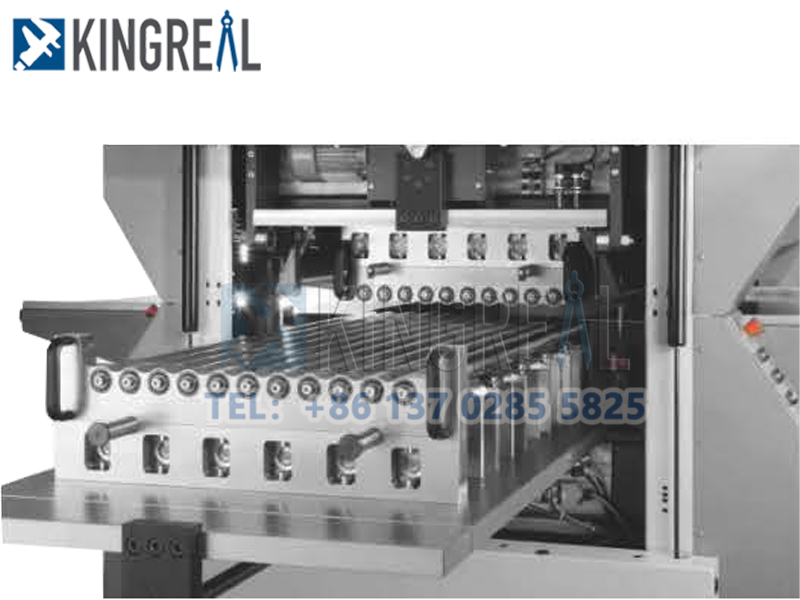

Special Technology -- Roller Box Pulling Technology

Special Technology -- Roller Box Pulling Technology

| The leveling roller supports and leveling roller bearings are mounted on a movable plate. When the upper leveling roller frame is electrically lifted, the movable plate is driven out of the equipment by the motor. After removing the front bearing shield, the rollers can be removed from the fixed rear bearing. In this way, the leveling rollers and support rollers can be cleaned outside the machine. The time required to clean leveling rollers, backup rollers, roller stands and gaps is significantly reduced due to good accessibility. |

|

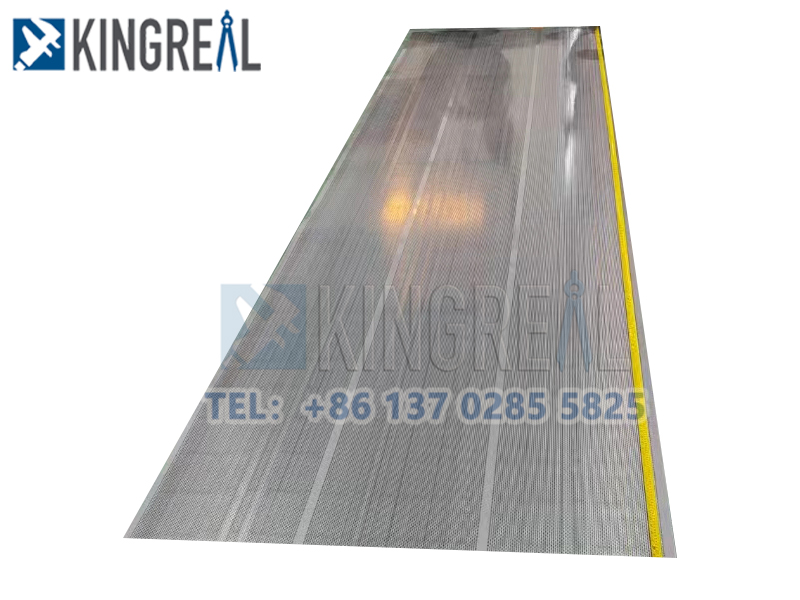

Products After 4-High Leveler Machine Process

Products After 4-High Leveler Machine Process

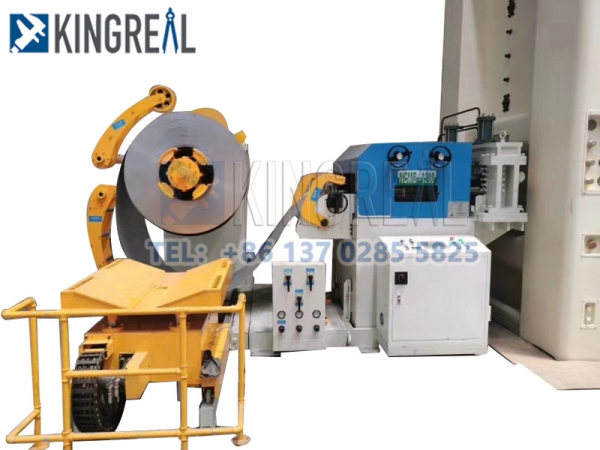

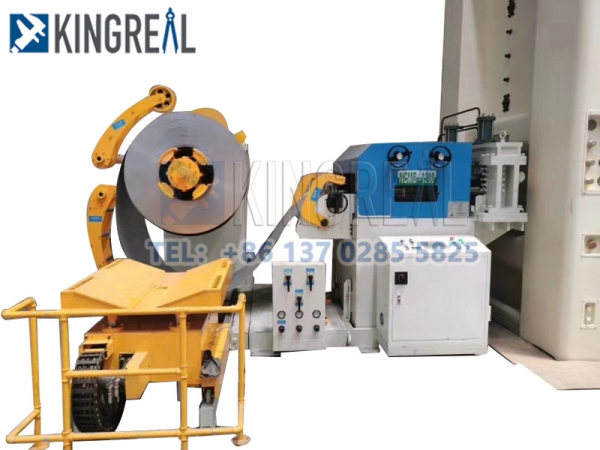

Decoiler - Feeder - Straightener 3 in 1

Decoiler - Feeder - Straightener 3 in 1

The 4-high leveler machine can combined with decoiler and feeder as a 3 in 1 machine to use. It is widely use in industrial production, the advantages of decoiler - Ffeeder - straightener 3 in 1 mainly include:

Highly integrated: Integrating multiple processes such as uncoiling, leveling, feeding and stamping into one production line, reducing the equipment footprint and improving work efficiency.

High degree of automation: Through the automatic control system, the production process can be automated, reducing manual operation errors and ensuring the consistency of product quality.

High precision: In a split production line consisting of a single material decoiler, leveling machine, and feeder, there is a waiting area between each piece of equipment. This prevents the running speed of each piece of equipment from being completely synchronized, thus affecting the production efficiency and Accuracy. The three-in-one feeder integrates the material decoiler, leveling machine, and feeder into one production line, making the machine‘s operation highly synchronized and ensuring the accuracy of the production line.

Material Saving: Due to precise material control, material waste can be reduced and production costs reduced.

Technology Support

Technology Support

KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements. After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

After-Sales Services

After-Sales Services  Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.